Feature Article

Moulds on Food – Potential Health Risks?

Mould, which is found everywhere in nature, can cause food spoilage. When bread is left at home for several days, grey patches of mould may be found on the surface, especially under the warm and humid climate of Hong Kong. We will analyse mould and its potential health risks in this article.

Potential Health Risks of Mould on Food - Mycotoxins

Although mould on food has an unpleasant appearance, incidents of acute toxicity resulting from consuming mouldy food are uncommon. However, certain types mould (e.g., Aspergillus fumigatus) can cause infections in humans, especially in patients with weakened immunity. Moreover, certain types of mould can produce toxic substances, known as mycotoxins, which can be harmful to humans. Humans can be exposed to mycotoxins directly or indirectly from the consumption of contaminated foods or food products (e.g. milk) produced from animals fed with contaminated feed.

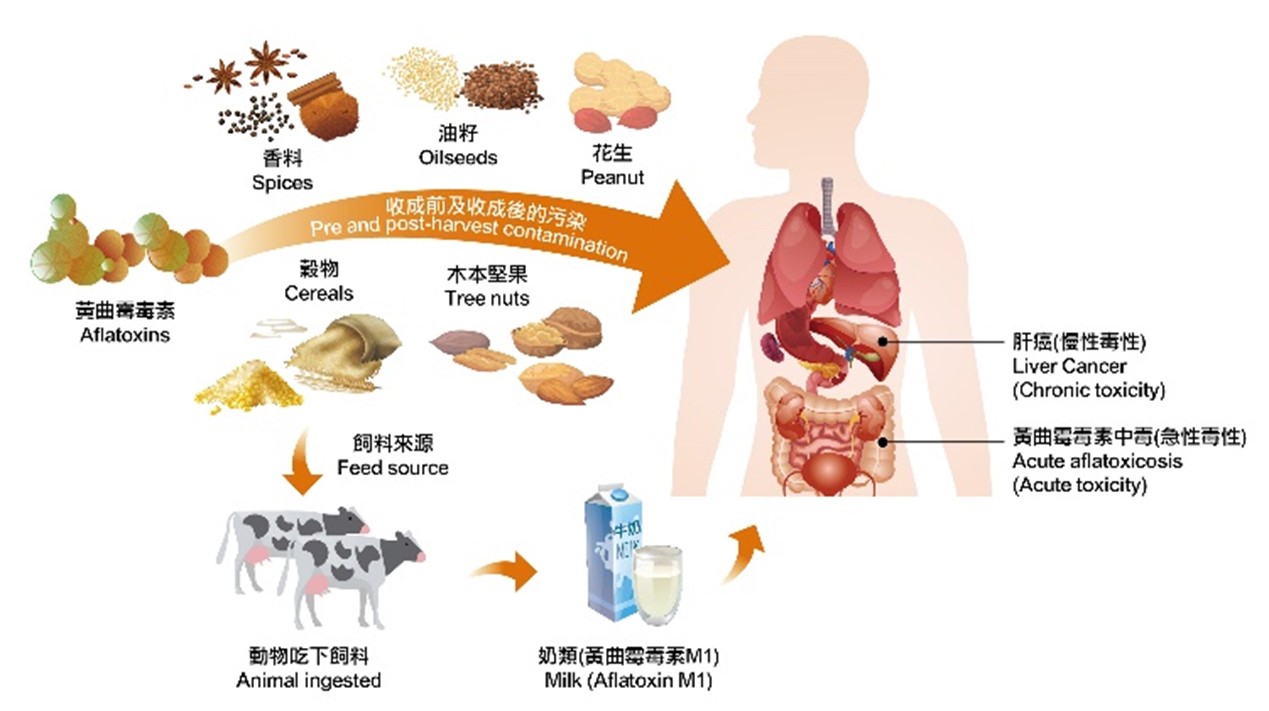

Figure 1: Various sources of human exposure to mycotoxins

Mycotoxins in Food

A wide variety of mould species have been identified to produce several hundred different mycotoxins. The most well-known ones are aflatoxins, patulin and deoxynivalenol, which will be further discussed in the following paragraphs.

Aflatoxins

Aflatoxins are amongst the most toxic mycotoxins, most commonly found in cereals, oilseeds, spices and tree nuts. Ingesting a large amount of aflatoxins can result in acute poisoning, i.e., aflatoxicosis, which could cause liver damage or even death. Long-term consumption of food contaminated with aflatoxins can cause liver cancer, and the risk of liver cancer associated with exposure to aflatoxins in individuals with hepatitis B virus (HBV) infection is much higher than that in non-HBV infected individuals.

Patulin

Patulin is most commonly found in rotten apples and apple products, including apple juice. Excessive exposure to patulin could cause nausea, gastrointestinal disturbances and vomiting in humans.

Deoxynivalenol

Deoxynivalenol (DON), also known as vomitoxin, is most commonly found to contaminate cereals, particularly wheat and maize. The primary health concern of DON in humans is its potential to induce acute illness with symptoms including nausea, vomiting, diarrhoea, abdominal pain and fever within a short time after ingestion.

Regulation of Mycotoxins in Food in Hong Kong

In Hong Kong, the legal limits for mycotoxins in food are stipulated in the Harmful Substances in Food Regulations (Cap. 132AF). The regulatory control of mycotoxins was further updated and tightened in the amendment exercise of the regulations in 2021. For example, the maximum limits of aflatoxins in certain tree nuts, peanuts and dried fruit which are more susceptible to aflatoxin contamination were tightened up (from 15-20 µg/kg to 10-15 µg/kg) considering the high food safety risks posed by aflatoxins to the local population. Moreover, given that DON is more commonly found in cereal-based food, and that infants and young children are more vulnerable to the toxic effects of DON, a maximum limit of 200 µg/kg has been established for food containing cereal intended to be consumed by infants and young children under the age of 36 months. For patulin, a maximum limit of 50 µg/kg has been established for patulin in apple juice and other beverages to which apple juice has been added.

How to Minimise the Risk of Mycotoxins?

Most mycotoxins are heat stable, and therefore cannot be removed by home cooking methods like roasting, baking and frying. As mycotoxins cannot be completely destroyed by cooking, prevention is the key to minimising our exposure to mycotoxins. Mould usually does not grow in properly dried and stored foods, so proper storage is an effective measure against mould growth and mycotoxins production. The Codex Alimentarius Commission has issued different codes of practice for the prevention and reduction of mycotoxins in various food commodities. The Centre for Food Safety (CFS) has also issued relevant guidelines for the food trade for the prevention and reduction of aflatoxin contamination.

Key Points to Note

-

Mould that produces mycotoxins can grow in a variety of foods, including cereals, oilseeds, spices and tree nuts.

-

Most mycotoxins are heat stable, and therefore cannot be removed by home cooking methods like roasting, baking and frying.

-

Mould usually do not grow in properly dried and stored foods, so proper storage is an effective measure against mould growth and mycotoxins production.

Advice to Consumers and the Trade

-

Purchase food from reliable shops and store them properly (e.g. follow the manufacturer’s instructions to keep them in a cool and dry place).

-

Discard food that looks mouldy or damaged.

-

Buy small amounts of food and consume them as soon as possible to prevent the food from turning mouldy.

-

Follow the relevant guidelines issued by the CFS and international authorities.

-

Maintain a balanced and varied diet to avoid excessive exposure to contaminants, including mycotoxins, from a small range of food items.

Mascot ON in Lesson

Vacuum Packaging – Keep Food Airtight and Safe

Having been used for preserving meat products since the 1950s, vacuum packaging has now become a widely adopted technique in the food industry. It offers a fast and effective way to preserve food by sealing it into packets, thereby reducing freezer burn, preventing odour transfer, enabling packaging and portioning of different foods, as well as extending the shelf life and reducing wastage through decreased spoilage. It is used by both commercial producers and domestic users. This article will examine the science behind vacuum packaging for food preservation, its synergy with other food processing techniques, and key points to note for storing vacuum-packed food.

Why is Vacuum Packaging Widely Adopted?

Vacuum packaging extends the shelf life of food by removing air, especially oxygen, around the food in the package, which is commonly achieved by vacuum pumps. This food preservation method is versatile and applicable to a wide range of food, including raw, cooked and ready-to-eat ones. The reduced-oxygen (anaerobic) environment slows down the growth of most microorganisms present in food and hence reduces the rate of deterioration. Besides, the airtight sealed packages prevent the surrounding air and water vapour from contacting the food surface, thus reducing the risk of cross-contamination.

One major benefit of vacuum packaging is that it can retain food in its natural state (in terms of juices, sauces, flavour and freshness) without the use of chemical preservatives. Chemical preservatives may alter the texture or taste of food. However, some food like fresh meat may undergo colour changes due to the absence of oxygen as natural pigments like myoglobin in meat will turn from bright red to purple red in vacuum condition. While this change may affect the appearance, it causes no food safety concern, and the colour of the food can be restored upon contact with air.

Figure 2: Examples of vacuum-packed food

Synergy between Vacuum Packaging and Other Food Processing Techniques

While vacuum packaging can be used alone to preserve food, it is often combined with other preparation and preservation methods to achieve optimal results. Sous vide refers to heating vacuum-packed food, such as raw meat and fish, at temperatures usually between 47℃ and 88℃ for 2 to 48 hours. Within the temperature danger zone, the moisture and nutrients in food favour bacterial growth. The vacuum pack plays an important role in preserving sous vide food by forming a physical barrier to prevent the food, in which its water content and nutrients favour bacterial growth in the temperature danger zone, from contamination by the surroundings.

Dehydration and freeze drying are common food preservation methods by reducing the moisture of food like cereals, fruits and vegetables. Dehydrated foods have a lower water content than fresh foods, making them less favourable for bacterial and fungal growth. Vacuum packaging complements these preservation methods by preventing dehydrated foods from re-absorbing moisture, thus further extending the shelf life of these foods.

Vacuum-Packed Food Is Not Sterile and Should be Stored Properly

Some believe that food kept in vacuum is safe irrespective of the storage temperature. Although vacuum packaging can protect food from external contaminants and limit its oxygen exposure, thereby slowing microbial growth, it is definitely not a sterilisation method. Therefore, additional food preservation methods, including refrigeration or freezing, may be required for storing vacuum-packed food. While aerobic microorganisms cannot thrive without oxygen, certain anaerobic pathogens, such as Clostridium botulinum and Listeria monocytogenes, can still survive and pose risks. For example, hot smoked fish and fresh chilled pasta have been reported to have Clostridium botulinum even when vacuum packed, whereas Listeria monocytogenes has been found in vacuum-packed smoked fish products. If a shelf-stable food product is desired, canning (in cans, jars or retort pouches) is required. During canning, food undergoes adequate heat treatment such as processing with steam under pressure, which destroys bacteria and spores, ensuring the food remains safe for extended periods without refrigeration.

Figure 3: Properly store vacuum-packed food and check the labels before consumption

Vacuum-packed food products should be stored at proper safe temperatures according to manufacturers’ instructions listed on the food labels, like refrigerating at 4℃ or below or freezing at -18℃ or below, and their expiry dates should be checked before consumption. Damaged packaging, even for vacuum-sealed food products, increases the risk of environmental contamination and spoilage. When in doubt about the packaging condition, the safest approach is to discard the product.

Spot Check

Safe Preparation of Pre-Cut Fruits and Fruit Juices

Pre-cut fruits and fruit juices are widely popular, especially during summer, as their convenience and refreshing qualities allow people to easily enjoy the nutritional benefits of fresh produce. However, large-scale food poisoning outbreaks involving cut fruits and fruit juices have been reported in various regions worldwide, with many cases linked to contamination with pathogenic microorganisms during various stages of production. Improper handling of these food products may pose significant risks of foodborne illnesses. This article will explore how to prepare and handle pre-cut fruits and fruit juices for commercial sale to ensure that consumers can enjoy them with peace of mind.

Understanding the Risks

Pre-cut fresh fruits and juices are considered high-risk foods because they often involve extensive manual handling and are typically consumed without undergoing heat treatment. Improper handling during preparation will significantly increase the risk of harmful bacteria surviving in the final product. Key pathogens of special concern include Listeria monocytogenes, Salmonella species and Shiga toxin-producing Escherichia coli (STEC), which can pose health risks like diarrhoea, fever and, in severe cases, kidney failure. Additionally, mouldy or damaged fruits may contain mycotoxins, specifically patulin. For example, patulin can persist in juices made from damaged apples and cause symptoms like nausea, gastrointestinal disturbance and vomiting in humans. By understanding these potential health risks and implementing appropriate control measures throughout the production process, contamination and deterioration can be minimised, ensuring the safety and quality of these products.

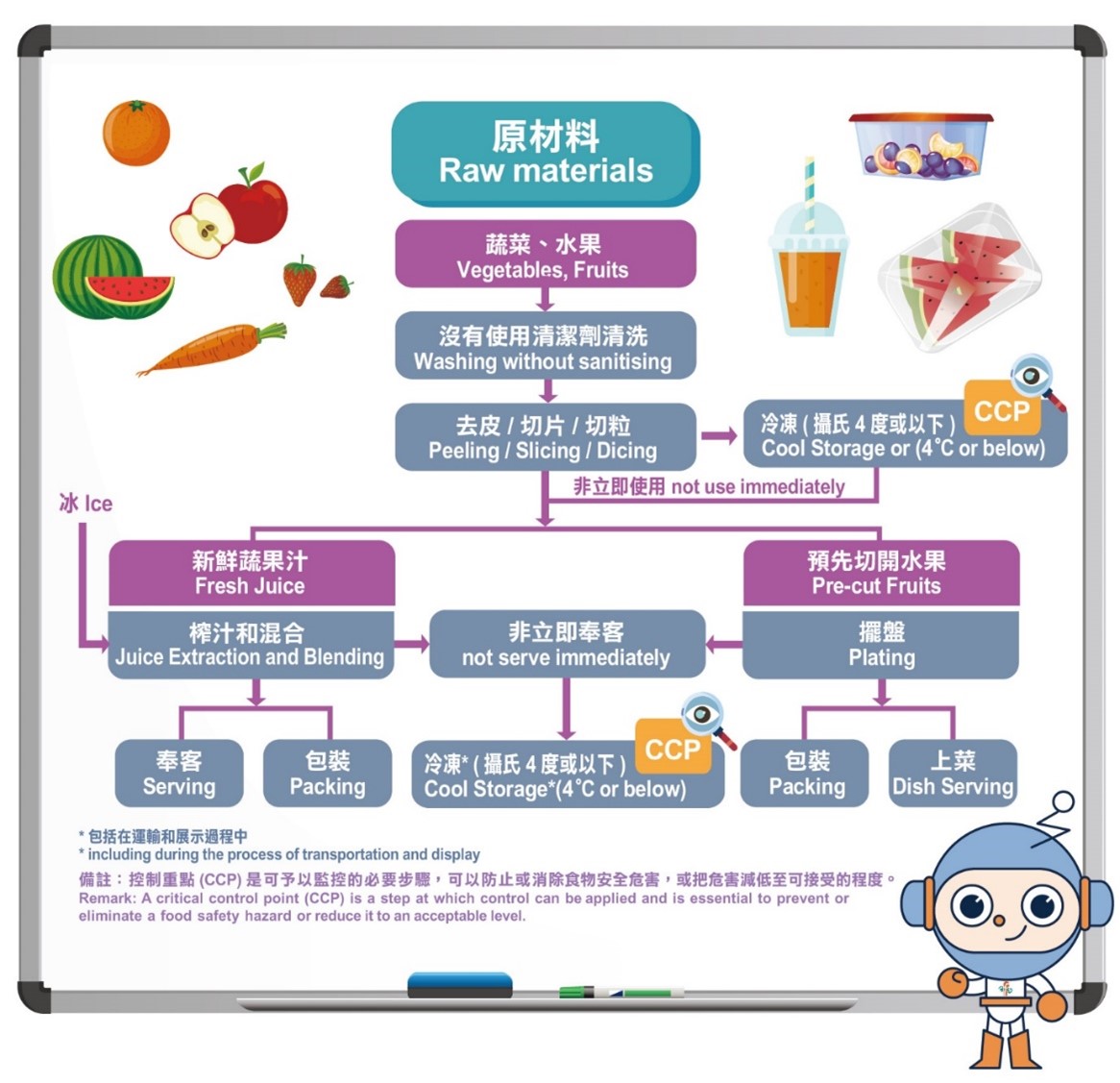

Figure 4: Flow diagram for preparing pre-cut fruits and fresh fruit and vegetable juices

Best Practices for Preparing Pre-cut Fruits and Fruit Juices

1. Choosing Fresh Produce

When purchasing fruits and vegetables as ingredients, always purchase from reliable suppliers and choose produce that is fresh, undamaged and free from bruises. Inspect fruits carefully upon receipt, as external damage may indicate internal issues. Chilled ingredients should be free from signs of temperature abuse, such as water or fluid stains on the packaging.

2. Proper Storage

Handle fresh produce with care to avoid bruising or damage. Store fresh fruits in the refrigerator and keep them away from raw food to prevent cross-contamination. Store fruits in a cool and dry place, preferably in the refrigerator at a temperature of 4°C or below. Highly perishable items like berries and grapes should be refrigerated immediately. All utensils, including disposable ones, should be stored in a clean and sanitary manner.

3. Washing Fruits

Always wash hands thoroughly with soap and water before handling any food. Before cutting or juicing, remove any damaged or mouldy produce and discard any rotten ones. Wash all fruits thoroughly under running water, ideally in a sink designated solely for this purpose. For firm-skinned fruits like melons, use a clean produce brush to remove surface dirt. Ensure that all utensils, machines and food preparation surfaces are cleaned and sanitised before use.

4. Cutting and Preparing

Use clean knives and cutting boards to cut fruits. Remove any bruised or damaged parts, as they can harbour harmful bacteria. Check the presence of internal mould when cutting the fruits and discard the mouldy ones. Use separate equipment and utensils for handling fresh ready-to-eat produce to minimise cross-contamination. If preparing fruit juices, ensure that any machinery used, such as juicers or blenders, is cleaned and sanitised.

5. Storing Pre-cut Fruits

Store cut or peeled fruits in airtight containers or wrap them tightly in plastic wrap before refrigerating them immediately at 4°C or below. Do not leave pre-cut fruits at room temperature for more than two hours. If water or ice is required for preparing juices, use only food grade ice or distilled or boiled water. Discard any leftover pre-cut fruits.

6. Serving and Consumption

It is best to serve pre-cut fruits or juices immediately after preparation. If the products are not consumed immediately, store them in clean containers with close-fitting cover at 4°C or below and label them with a use-by date. Do not leave pre-cut fruits or juices at above 4°C for more than two hours. Keep the display area clean and inspect the products regularly. Discard any items showing signs of deterioration.

Conclusion

Pre-cut fruits and fruit juices require extensive manual handling and are often consumed without heat treatment, making strict adherence to safe handling practices critical. A preventive food safety management system such as a Food Safety Plan Note 1 based on Hazard Analysis and Critical Control Points should be implemented for identification and control of food safety hazards at every stage of food production. Food businesses should strictly adhere to the established hygiene and safety guidelines when preparing and selling pre-cut fruits and fresh juices. For more information, please refer to the full set of guidelines on the CFS's webpage.

Note 1: To learn more about how to implement a Food Safety Plan, please visit:

https://www.cfs.gov.hk/english/programme/programme_haccp/programme_haccp_industry_safe.html

Safe Kitchen/Food Safety Guidelines

Introduction to "Safe Kitchen" Scheme

To facilitate the adoption of the 5 Keys to Food Safety and Good Hygiene Practices (GHPs) by trade members, and ensure food safety in their daily operation, the CFS has integrated the existing channels of risk communication and launched a new platform, namely “Safe Kitchen”, to communicate with the trade. The platform provides food safety information of greater practical importance to meet the operational needs of catering outlets.

The "Safe Kitchen" platform disseminates up-to-date food safety information (including food safety guidelines and legislative amendments) to the trade through a host of channels including WhatsApp, emails and dedicated websites.

Under the "Safe Kitchen" Scheme, training materials tailor-made for the trade and workshops for kitchen staff will be provided to enhance their food safety and hygiene awareness. Members of the trade are welcome to scan the relevant QR code to download the registration form for the “Safe Kitchen” Scheme in order to receive the latest food safety information in a timely manner

Food Safety Guidelines:

Street Food Stalls – Food Safety Guidelines for Food Businesses

Hong Kong's street food is renowned far and wide, but the hectic operating environment makes the trade prone to overlook food safety. Street Food Stalls – Food Safety Guidelines for Food Businesses ("the Guidelines") published by the CFS provides practical advice for both permanent and temporary food stalls, assisting the trade in ensuring food quality within limited spaces.

The Guidelines cover five major areas:

- Personal hygiene: staff should wear clean clothing, treat their wounds or cuts properly, and wash their hands thoroughly before handling food;

- Environment management: keep the work area clean, sanitise utensils regularly, and ensure that the drainage system is clear;

- Handing of food ingredients: store raw food from cooked food separately and strictly control refrigeration temperatures (hot food above 60°C and cold food below 4°C);

- Notes for temporary stalls: organisers are required to provide water, electricity and waste disposal facilities, while vendors should adopt simple cooking methods and retain records of food ingredient sources;

- Temperature monitoring: use a food thermometer and follow the “2-hour/4-hour” rule for displaying food at room temperature to avoid the risk of deterioration.

The Guidelines also include an illustrated guide, enabling staff to quickly grasp the key points. By adopting these voluntary measures, the trade can enhance hygiene standards while upholding Hong Kong’s reputation as a "culinary capital". Members of the trade could click the following link or scan the relevant QR code to view or download the Guidelines online for reference.

https://www.cfs.gov.hk/english/multimedia/multimedia_pub/files/Street_Food_Stalls_Booklet_eng.pdf

News on CFS

1. Watch and Learn – Let’s Subscribe to the CFS WhatsApp Channel

A verified Blue Check badge has been added to the CFS’s newly launched official WhatsApp channel. This certification shows that WhatsApp has confirmed the authenticity of the CFS's channel. By subscribing to the channel, one can obtain timely updates on local food safety matters and food safety information. These include links to educational videos, food alerts and various food safety related activities. The posts on the channel are enhanced with graphic illustrations and clear explanations to help the public grasp key food safety messages effectively.

To subscribe to our official WhatsApp channel (in Chinese only), one can scan the QR code in the illustration below, press "Follow" and click the "bell". Besides, the CFS posts regularly on various social media platforms, such as Facebook and Instagram, and uploads different videos on YouTube to enhance its communication and interaction with the public

2. Webinars on "Safe Food at School" and "Food Safety of Student Lunch Boxes" for 2025/26 School Year Held by CFS

The CFS is committed to ensuring food safety at school by conducting yearly and territory-wide inspections of licensed food factories supplying lunch boxes for schools and organising trade talks to remind lunch box suppliers to adhere to Good Hygiene Practices when preparing food. With the approach of the 2025/26 school year, the CFS held webinars on “Food Safety of Student Lunch Boxes” for student lunch box suppliers on 26 June and 19 August and "Safe Food at School" for school staff on 11 July. They covered the safety issues of lunch boxes, high-risk foods, the risk of choking and food allergies, etc. Suppliers were also reminded to follow basic food hygiene/safety principles and ensure that staff members observe good personal and environmental hygiene.

3. Food Safety Talks for Designated Catering Service Providers of National Games

To support the preparation work for the 15th National Games (NG) in 2025 and ensure the highest standards of food safety and hygiene for athletes and guests during the event, the CFS organised food safety training talks for management personnel and catering staff of designated reception hotels for the 15th NG on 7 August, 26 August, 30 September, 21 October and 5 November 2025.

4. Specialised Talks on Food Safety Advice for Manufacture of Frozen Confections Held by CFS

Food traders, particularly those handling high-risk foods such as frozen confections, need to be vigilant in summer, when the hot and humid climate of Hong Kong presents a higher food safety risk. To enhance the trade’s awareness in this area, the CFS held specialised talks on 27 August and 11 September 2025 to provide food safety advice for the manufacture of frozen confections, and explain the keys points on food safety control in the manufacture and sale of frozen confections to prevent food poisoning incidents.

5. Technical Meeting with the Trade on the Food and Drugs (Composition and Labelling) (Amendment) Regulation 2025 for Regulation of Konjac-containing Jelly Confectionery

The Food and Drugs (Composition and Labelling) (Amendment) Regulation 2025 (Amendment Regulation) was passed by the Legislative Council on 20 August 2025 and is scheduled to take effect on 1 April 2026 to strengthen the regulation of prepackaged konjac-containing jelly confectionery. The Amendment Regulation stipulates that mini-cup konjac-containing jelly confectionery with a height or width not exceeding 45 millimetres is prohibited for sale, and that other konjac-containing jelly confectionery must be labelled with choking warning statements on their packaging to remind consumers, especially children and the elderly, to exercise caution during consumption. Given that the product design and texture of mini-cup konjac jellies may increase the risk of choking, the Government has also been promoting relevant health education through various channels to enhance public awareness of safe consumption of konjac jellies. To facilitate the trade’s understanding of and compliance with the new requirements, the CFS has developed a set of guidelines for the trade, and held a technical meeting with the trade on 28 August 2025.

6. The 90th Meeting of the Trade Consultation Forum

The 90th meeting of the Trade Consultation Forum was held on 19 September 2025. The CFS and the trade exchanged their views on topics including “Food Safety Guidelines for Street Food Stalls”, “Food Safety Advice on Prepared Dishes”, “The Food and Drugs (Composition and Labelling) (Amendment) Regulation 2025 for Regulation of Konjac-containing Jelly Confectionery”, and “Food Labelling of Prepackaged Food in Hong Kong”. For details of the event, please visit the following webpage or scan the relevant QR code:

https://www.cfs.gov.hk/english/committee/Notes_and_Presentation_Materials_TCF90_20250919.html

Ask Our Mascots

Observe Hand Hygiene

Why did Mascot ON switch to food-handling gloves?

Oh, so he’s making sandwiches. Washing hands thoroughly is surely the most effective way to maintain hand hygiene (Please visit the following website or scan the relevant QR code for the hand washing steps: https://www.cfs.gov.hk/english/trade_zone/safe_kitchen/Hand_hygiene.html)

If you need to wear gloves when handling read-to-eat food, make sure you use them properly, otherwise you might actually increase the risk of cross-contamination of food. Imagine if you wear the same pair of gloves to take out the garbage, clean tables, cut raw meat, and then make sandwiches, bacteria around the area are likely to be transferred to the read-to-eat food via the gloves. If someone eats them, the consequences could be unimaginable!

Key points on proper use of gloves:

- Wash hands thoroughly before putting on and after taking off gloves. Rub hands with water and liquid soap for 20 seconds;

-

If there are wounds on hands, cover them properly with waterproof bandages before wearing gloves;

-

Gloves should be replaced at the appropriate time, such as when they become dirty or torn, or after switching jobs or procedures.

Keep in mind that wearing gloves is no substitute for hand washing. To eat with peace of mind, pay attention to hand hygiene. Let’s go over the key points of handwashing :

https://www.cfs.gov.hk/english/consumer_zone/safefood_all/clean_hygiene.html

Enhancement Quiz

- Regarding the regulation of mycotoxins in food in Hong Kong, which of the following statements is in line with the information provided in the article?

-

The limits of mycotoxins were significantly relaxed in the amendment exercise of the Harmful Substances in Food Regulations in 2023.

-

The maximum level of DON in cereal-based food for infants and young children is 200 µg/kg.

-

The limit of patulin in apple juice is 100 µg/kg.

-

A uniform limit of 5 µg/kg has been established for aflatoxins in all tree nuts.

-

- Which of the following statements about vacuum packaging is correct?

-

Vacuum packaging can completely eliminate bacteria and preserve food for extended periods without freezing or refrigeration

-

Vacuum packaging slows down the growth of microorganisms by reducing the oxygen content, thereby prolonging the shelf life of food

-

Vacuum-packed food does not undergo colour changes due to the absence of oxygen and always looks fresh

-

Vacuum packaging cannot be used in combination with food processing techniques like dehydration and sous vide

-

- Which of the following measures is most effective in reducing the food safety risks associated with pre-cut fruits and fruit juices?

-

Attract customers by storing fruits in brightly coloured containers

-

Wash fruits thoroughly under running water and use a clean produce brush before cutting them

-

Store pre-cut fruits at room temperature to maintain their fresh taste

-

Only use disposable knives to cut fruits to reduce costs

-

Diary of Mascot ON

Little-known Facts about Fried Rice

To make fried rice that’s fluffy and dry, many may opt for chilled rice. The key to food safety for frying "cold rice" actually lies in how you cool the rice down!

Many people simply leave cooked rice at room temperature and then add ingredients to make fried rice. This is very risky indeed! If the rice is contaminated with Bacillus cereus while cooling at room temperature, and remains in this temperature danger zoneNote1 for a long time, spores will germinate and produce toxins that can cause food poisoning in those who consume the fried rice. It turns out that the spores and toxins produced by Bacillus cereus are heat-stable. Even if cooked, "cold rice" contaminated with Bacillus cereus cannot eliminate the spores and toxins already produced.

So what is the proper way to fry rice then? Keep in mind the "two-stage cooling method".

- The first stage

Freshly cooked food (i.e. rice) must be cooled down to 20°C within two hours.

Tips for speeding up the cooling process: spread out the food or cut it into small portions, place it in a shallow covered dish in a well-ventilated area to speed up cooling.

- The second stage

Cool food from 20°C to 4°C within four hours.

Tips for refrigeration: Cooked food to be refrigerated must be wrapped properly or put in an airtight container and kept separate from raw food in the refrigerator.

Make sure the chilled rice mixed with ingredients must be cooked thoroughly before serving!

Key points review:

https://www.cfs.gov.hk/english/trade_zone/safe_kitchen/cooling.html

Note1: To learn more about the temperature danger zone and the 2-hour/4-hour rule, please visit the following webpage or scan the relevant QR code:

https://www.cfs.gov.hk/english/trade_zone/safe_kitchen/Temperature_Danger_Zone.html