Food Safety Focus (229th Issue, August 2025) – Article 2

Keeping Non-prepackaged Frozen Confections Safe

Reported by Mr. Kenneth YIP, Scientific Officer,

Risk Communication Section, Centre for Food Safety

Frozen confection refers to any confection such as soft ice-cream and frozen yogurt commonly sold for human consumption in a frozen or chilled state. While some may assume that frozen confections are always safe due to low storage temperatures, the lack of prior heat treatment to eliminate pathogens before consumption makes them high-risk foods. This article will highlight foodborne pathogens that may be found in frozen confections, discusses the food safety challenges at points of sale, outlines control measures in reducing food safety risks, and offers tips for safe consumption.

Freezing Does Not Eliminate Microbiological Hazard:Pathogens Can Still Survive

Listeria monocytogenes is ubiquitous in the environment and may be present in frozen confections. The bacteria have been detected in milk harvested from cattle in ruminant farms used for producing the flavours of frozen confections. Listeria monocytogenes is able to survive at low temperatures, and can even grow in refrigerated food. Consuming food contaminated by the bacteria can result in listeriosis with gastrointestinal symptoms and even severe complications like septicaemia. Listeria monocytogenes infection is particularly risky for pregnant women as it can lead to miscarriage, stillbirth, preterm birth and septicaemia or meningitis in the newborns.

When manufacturing frozen confections, eggs are another ingredient which provides the desirable texture. Salmonella can be found in contaminated eggs from infected hens. Using unpasteurised egg products for food preparation can further increase the microbiological risk. Patients infected by Salmonella can come down with salmonellosis with symptoms such as watery diarrhoea, stomach cramps and vomiting.

Be Vigilant to Inadequate Cleaning and Disinfection Practices

While cleaning such as mopping or rinsing aims to physically remove germs, dirt and foreign substances from surfaces, disinfection serves to kill the remaining microorganisms by disinfectants. In general, cleaning should be performed before disinfection. Incomplete or improper cleaning and disinfection during food preparation are contributing factors of contamination of frozen confections, which raise the food safety risk.

When preparing non-prepackaged frozen confections, various equipment and utensils are used. These include ice- cream or frozen yogurt dispensing machines and scoops for collecting ice-cream. Since some of the machinery parts such as nozzles are unavoidably exposed to non-sterile conditions at room temperature during operation, these parts are prone to environmental contamination and might promote bacterial growth in the trace amounts of frozen confections left in the machines. Scoop handling may involve repeated manual workflows and multiple contacts between the scoop and different containers, thus raising the risk of cross-contamination between different surfaces. Incomplete or improper cleaning and disinfection practices of equipment and utensils could lead to the proliferation of pathogens.

Proper Hygiene is Indispensable to Securing Food Safety

As stipulated in the Frozen Confections Regulation (Cap. 132AC), food premises selling frozen confections should possess relevant food business licences. Frozen confections for sale should not contain more than 50 000 bacteria per gram or more than 100 coliform bacteria per gram. In addition, every refrigerating device used for storing frozen confections should be kept in a clean condition and maintained in good order. Utensils used for serving or handling frozen confections are required to be kept clean and free from the risk of contamination. Staff handling frozen confections should keep good personal hygiene.

To reduce food safety risks of non-prepackaged frozen confections, cleaning is essential as it removes dirts and food residues which allow microorganisms to grow. Soft ice-cream and frozen yogurt dispensing machines should be cleaned and disinfected according to the manufacturer’s instructions. Approved bactericidal agents and food-grade disinfectant solution should be used for washing and immersing the machine parts. The unused food ingredients should be drained and discarded after food business operation. All removable parts should be dismantled, washed by disinfectant and rinsed by drinking water.

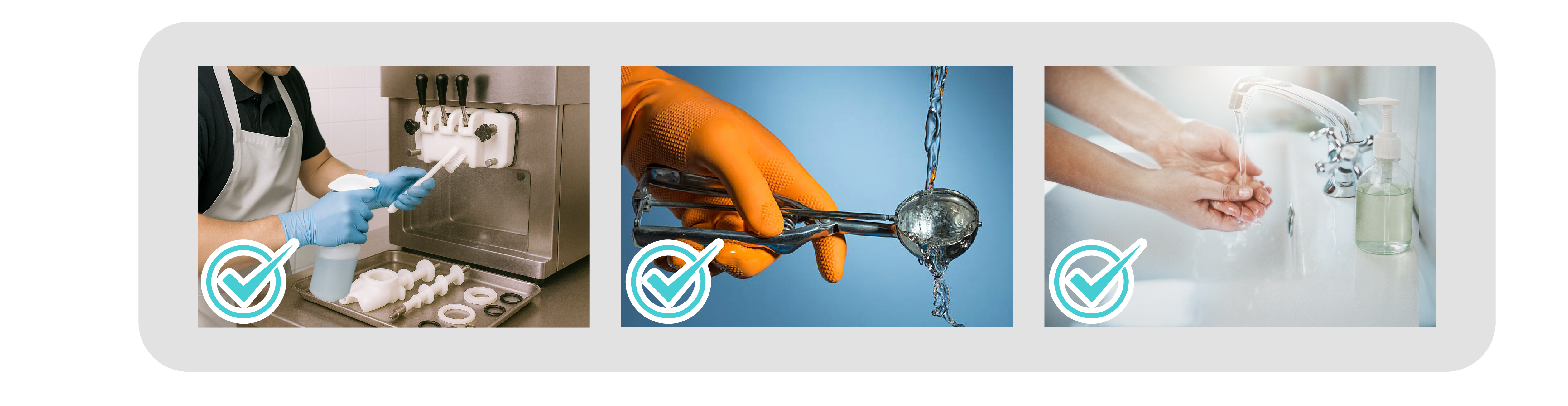

For scoop serve frozen confections, clean and disinfect all utensils, including scoops, before and after use, as well as regularly during operation. Wash, disinfect and dry the lids of the frozen confection containers before placing them back on the containers. Separate washing facilities should be available for hand washing and food preparation to reduce the risk of cross-contamination. Food premises should also adhere to Good Hygiene Practice during food preparation. The figures below illustrate some salient hygienic measures that can be adopted to minimise the risks of non-prepackaged frozen confections.

Figure 2: Hygienic measures including (i) dismantle the machine parts (left), (ii) rinse and disinfect the scoop (middle), and (iii) wash hands thoroughly (right) minimise the risk of non-prepackaged frozen confections