Food Safety Focus (181st Issue, August 2021) – Food Safety Platform

The Juicy Truth about Cold-pressed Juice

Reported by Mr. Arthur YAU, Scientific Officer,

Risk Communication Section, Centre for Food Safety

Vegetables and fruits are part and parcel of a healthy diet, yet we are often too busy to purchase and prepare them for consumption — a modern-life dilemma one may frequently encounter. In recent years, prepackaged juice has been marketed as a convenient way to get a boost of nutrients from a bottle of what hopefully is something delicious. However, making the prepackaged juice free from any disease-causing microorganisms is more important from the perspective of food safety.

What is Cold-pressed Juice?

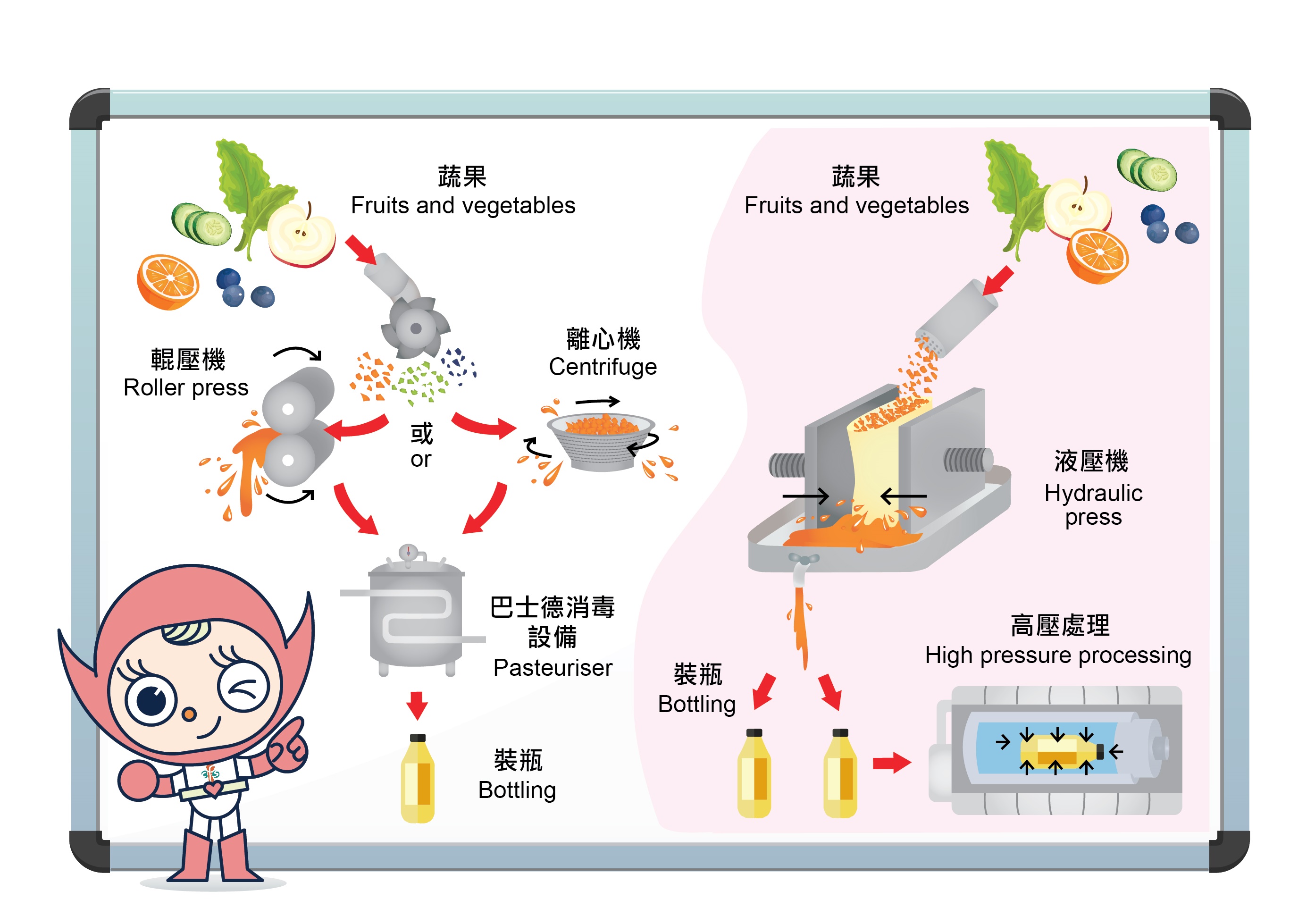

Conventional commercial juice production operations often produce juice by cutting produce into small pieces by machines with spinning metal blades, followed by separating the juice from fruit flesh with centrifuges. Lately, some local manufacturers have introduced “cold-pressing” as an alternative way of juicing. It involves pressing shredded fruits and vegetables with a hydraulic press to squeeze out most of the juice from the pulp. Cold-pressing does not reduce the microbial load in the products. Therefore, cold-pressed juice usually has a short shelf life of a few days under refrigeration. Studies so far do not reveal any significant differences in the nutrition contents between cold-pressed and comparable conventionally processed juices, despite the former claiming to involve less heat treatment.

Figure 2: Comparison of conventional (left) and cold-pressed juice processing

Food Safety Risks of Cold-pressed Juice

Fruits and vegetables may harbour bacteria that exist in soil or water in the farm environment, thereby contaminating the produce and its products. Fresh produce can also become contaminated after being harvested, such as during packing, transportation, storage or preparation. Consumption of contaminated produce or its products can lead to foodborne illness. This is especially serious in susceptible individuals such as the elderly, babies and young children, pregnant women and people with weakened immunity (e.g. persons taking antibiotics, antacids). Untreated juices have a greater risk of contamination by foodborne microorganisms such as Salmonella and E. coli O157:H7, both of which can survive in the acidic environment of most fruit and vegetable juices.

Pasteurisation and High Pressure Processing

Locally, chilled prepackaged juices often have undergone heat treatment, such as pasteurisation, during production. The heat treatment aims to kill harmful microorganisms, reduce the amount of spoilage organisms, and inactivate enzymes that lead to quality loss. On the other hand, cold-pressing itself is only a juice extraction process. To extend the shelf life of cold-pressed juices without applying heat, some producers choose to use high pressure processing (HPP) to reduce the microorganisms in juices.

HPP subjects foods to high pressures of thousands of times of atmospheric pressure. The technique kills bacteria by disrupting their cell membranes beyond repair. HPP is a relatively new food preservation method, and studies find that HPP alone at ambient temperature does not destroy spores from foodborne pathogens like Clostridium botulinum. Some overseas food authorities require the manufacturers to combine HPP with other processes, usually elevated temperature, to effectively inactivate spores. Whichever food preservation method, thermal or non-thermal, is used, the manufacturers should validate all control points of the juice production to ensure sufficient reduction of the pertinent microorganisms is achievable.

Advice to the Trade

- Follow Good Manufacturing Practices from purchasing raw materials to the whole production process.

- Any food preservation methods, thermal or non-thermal, applied in the juice production process should be validated to secure sufficient microbial reduction.

- Store all fruits and vegetables at 4°C or below once cut. Regularly clean and sanitise all utensils and equipment thoroughly.

- Maintain good personal hygiene at all times.

- Avoid prolonged storage, which affects the quality and safety of juices. Distribute and sell finished products on a first-in-first-out basis.

Advice to the Public

- Cold-pressed juice usually has a short shelf life. If not consumed immediately after purchase, cold-pressed juice must be refrigerated and consumed before expiry.

- Susceptible populations should avoid drinking juices without pasteurisation or equivalent processes to kill harmful bacteria.

- Consume the whole fruit instead of juice in order to also get the benefits of dietary fibres and reduce intake of free sugars.