Slaughterhouses

The territory's fresh meat (beef, pork and mutton) supply comes from two licensed slaughterhouses, namely Sheung Shui Slaughterhouse and Tsuen Wan Slaughterhouse, with an average daily throughput of about 3,072 pigs, 25 cattle and 2 goats. The Food and Environmental Hygiene Department is responsible for the monitoring of slaughterhouses to ensure that their operations meet the required hygiene and environmental standards and that only meat fit for human consumption is released for sale in the market. Qualified health inspectors are stationed at the slaughterhouses to perform meat inspection and other related duties, including monitoring the operation of slaughterhouses and arrangement of meat delivery, etc.

Slaughtering processes

The process of slaughtering and dressing of food animals generally involves:

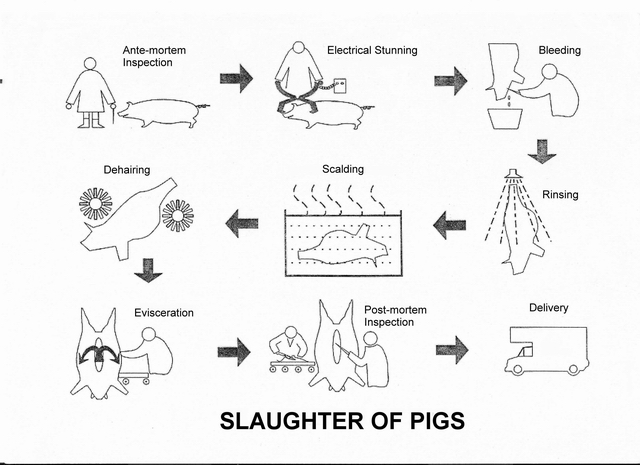

For pigs

- Ante-mortem Inspection - all pigs are inspected by the Ante-mortem Inspection Unit of the Slaughterhouse (Veterinary) Section. Suspected diseased or injured pigs are screened out for isolation slaughter. (http://www.cfs.gov.hk/english/import/import_ami.html)

- Electrical Stunning - pig is rendered unconscious electrically by an automatic stunning machine.

- Sticking and Bleeding - the unconscious pig is killed by the process of sticking into a group of veins and arteries at the neck and then bled over a bleeding trough.

- Rinsing - the animal body is rinsed by shower after bleeding to remove blood stains from its skin.

- Scalding - this is done by hanging pig forward into a long scalding chamber with hot water at about 58℃.

- Dehairing - pig is dehaired by a mechanical dehairing machine.

- Evisceration - a longitudinal incision is made from the pubis to the neck to remove the offal.

- Post-mortem inspection - every carcass and offal is inspected by Health Inspectors. Only meat and offal that are fit for human consumption will pass the inspection and unfit meat / offal / parts will be condemned.

- Stamping - the pig carcass and offal passed the inspection will be applied with "Government Inspected" stamp to signify that they are inspected.

- Marking - each carcass is marked with a production number in sequence and the shopsign of the meat stall corresponding to the tattooed farm and trade codes.

- Delivery - the pig carcasses and offal are transported by meat delivery vehicles to individual retail outlet.

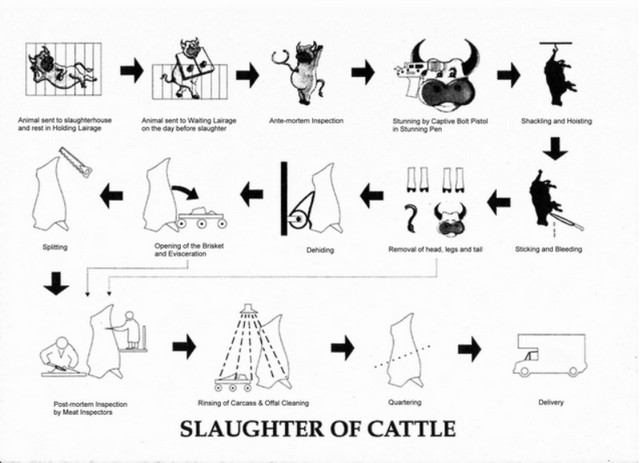

For cattle

- Receiving live cattle - cattle sent to slaughterhouse and rested in the Holding Lairage and then sent to the Waiting Lairage on the day before slaughter.

- Ante-mortem inspection - all cattle are inspected by the Ante-mortem Inspection Unit of the Slaughterhouse (Veterinary) Section. Suspected diseased or injured cattle are screened out for isolation slaughter. (http://www.cfs.gov.hk/english/import/import_ami.html)

- Stunning - cattle is rendered unconscious by a shot from a pneumatic captive bolt into the brain.

- Shackling and hoisting - the stunned animal is shackled by the left hind leg. It is then hoisted onto the overhead conveyor railing and pushed to the sticking point.

- Sticking and Bleeding - a cut is made at the neck to sever a group of blood vessels including jugular veins. The animal is bled by passing slowly over the bleeding trough.

- Removal of the head, legs and tail - the forelegs, the head and the tail are removed from the carcass. The tail and forelegs are put into a plastic bag to prevent contamination to the carcass. Whilst the head is hanged up for inspection.

- Dehiding - the hide is chained and pulled off at the flank by a hide puller.

- Open the brisket and evisceration - the brisket is cut by an electric saw. Offal is taken out and dropped onto the large moving viscera table.

- Carcass splitting - the carcass is split longitudinally by an electric saw along the vertebral column into two halves.

- Carcass and offal inspection - the carcass and offal are inspected by Health Inspectors. Only meat and offal that are fit for human consumption will pass the inspection and unfit meat / offal / parts will be condemned.

- Stamping - the inspected carcass and offal which are fit for human consumption will be officially stamped.

- Rinsing of carcass and offal cleaning - The carcass is then rinsed in rinsing chamber, and offal is cleaned at offal washing room.

- Quartering - each side of the beef carcass is cut into two quarters between the 5th and 6th ribs by mechanical scissors in the Quartering Area.

- Meat delivery - beef quarters, offal and other parts of cattle are sent to the Meat Despatch Bank, and then are collected and delivered by meat delivery vehicles to individual retail outlet.

For goats

- Ante-mortem inspection - all goats are inspected by the Ante-mortem Inspection Unit of the Slaughterhouse (Veterinary) Section. Suspected diseased or injured goats are screened out for isolation slaughter. (http://www.cfs.gov.hk/english/import/import_ami.html)

- Stunning - the goat is rendered unconscious by a hand held electrical stunner.

- Sticking and Bleeding - the unconscious goat is killed by the process of sticking into a group of veins and arteries at the neck and then bled over a bleeding trough.

- Rinsing - the animal body is rinsed by shower after bleeding to remove blood stains from its skin.

- Scalding - this is done in a scalding tank with hot water at about 60℃.

- Dehairing - the goat is then dehaired by a mechanical dehairing machine.

- Evisceration - a longitudinal incision is made from the pubis to the neck to remove the offal.

- Rinsing of carcass and offal cleaning - the carcass and offal are then rinsed.

- Post-mortem inspection - the carcass and offal are inspected by Health Inspectors. Only meat and offal that are fit for human consumption will pass the inspection and unfit meat / offal / parts will be condemned.

- Stamping - the inspected carcass and offal which are fit for human consumption will be officially stamped.

- Delivery - the goat carcass and offal are transported by meat delivery vehicles to individual retail outlet.

Management & Hygiene of Slaughterhouses

With the introduction of private sector commitments to manage and operate the slaughterhouses, the Department is responsible for the supervision, inspection and enforcement of meat hygiene therein. Our aim is to safeguard public health through fair, consistent and effective enforcement of hygiene and inspection regulations, namely the Public Health and Municipal Services Ordinance, Cap. 132 and its subsidiary legislations, such as the Slaughterhouses Regulation and the Food Business Regulation.

We station qualified and specialised staff in the licensed slaughterhouses so as to monitor the operation of the slaughterhouse by the respective operators and ensure good hygiene practices. In addition, we liaise closely with overseas controlling authorities and keep in view the development of the legislations, policies, strategies and the code of practices about the management and hygiene of slaughterhouses in other countries so as to improve the quality of our services.

Click the topics below if you wish to learn more about the management and hygiene of slaughterhouses

Food Safety / Inspection, AMI (American Meat Institute)

Food Safety and Inspection Service (FSIS), United States Department of Agriculture (USDA), United States of America

Foodlaw - Reading Department of Food Bioscience, The University of Reading, United Kingdom

Meat inspection (ante-mortem inspection and post-mortem inspection inclusive)

All animals intended for human consumption and admitted to the licensed slaughterhouses for slaughtering and dressing are subject to both ante-mortem and post-mortem inspections. Before food animals are slaughtered, they are kept in the lairages for ante-mortem inspection carried out by the Ante-mortem Inspection Unit of the Slaughterhouse (Veterinary) Section. (http://www.cfs.gov.hk/english/import/import_ami.html)

Ante-mortem inspections aims to screen out suspected diseased or injured animals for isolation slaughter. During ante-mortem inspection, the welfare of food animals in slaughterhouses is also taken care of by preventing avoidable pain, suffering or excitement in the course of handling and waiting for slaughter.

Post-mortem inspections are also conducted by health inspectors at the slaughter halls or isolation slaughter rooms as soon as the food animals are slaughtered and dressed. Post-mortem inspections include:

Post-mortem inspections are also conducted by health inspectors at the slaughter halls or isolation slaughter rooms as soon as the food animals are slaughtered and dressed. Post-mortem inspections include:

- visual inspection of the animal carcass and offal;

- examination of lymph nodes, in particular the submaxillary and bronchial, by multiple incisions along their main axis;

- palpation of the organs, in particular the lungs, the liver, the spleen, the uterus, the udder, and in cattle, also the tongue;

- investigation for abnormalities in consistency, colour and smell;

- examination for parasitic infections by multiple incisions of the parasites' predilection sites, such as the internal and external masseters for cysticercosis in pigs, the gastric surface of the liver for fascioliasis in cattle and goats; and

- whenever necessary, taking pork samples for microscopic examination of trichinosis and fatty tissue samples for boiling test of jaundice.

Conditions warranting condemnation of the carcasses, offal and blood

Only animal carcasses and offal which have passed the meat inspections can be marked with a "Government Inspected" stamp and released for sale in the market. If, upon inspection of any carcass and offal, the health inspector is satisfied that the animal is suffering from any disease or condition rendering the carcass or the affected parts unfit for human consumption, he/she shall condemn the animal carcass, offal or the affected parts, as the case may be, and order for their destruction.

The carcass, offal and blood of a food animal will be totally condemned if it exhibits any of the following diseases or conditions:

| Actinobacillosis (generalized) | Actinomycosis (generalized) | Anaemia (advanced) |

| Anthrax | Blackleg | Bruising (extensive and severe) |

| Caseous lymphadenitis with emaciation | Caseous lymphadenitis (generalized) | Cysticercus bovis (generalized) |

| Cysticercus cellulosae | Cysticercus ovis (generalized) | Decomposition (generalized) |

| Emaciation (pathological) | Fever | Foot and mouth disease associated with febrile condition |

| Gangrene (moist) | Glanders | Harmful residues of antibiotics, hormones or chemicals |

| Imperfect bleeding accompanied by systemic changes | Jaundice | Malignant catarrhal fever |

| Mastitis (acute septic) | Melanosis (generalized) | Melioidosis |

| Metritis (acute septic) | Oedema (generalized) | Pericarditis (acute diffuse septic) |

| Pleurisy (acute diffuse septic) | Pneumonia (acute septic) | Pyaemia (including joint-ill) |

| Sarcocysts (generalized) | Septicaemia | Sparganosis |

| Toxaemia | Swine erysipelas (acute febrile) | Swine fever |

| Tetanus | Trichinosis | Tuberculosis (generalized) |

| Tuberculosis with emaciation | Tumours (malignant with secondary growths) | Tumours (multiple) |

| Uraemia |

Other duties of health inspectors

Health inspectors working in the licensed slaughterhouses, apart from meat inspection duties, have to monitor/control the slaughtering operations with proper regard to:

- the prevention of cruelty to animals;

- the method of slaughtering and meat hygiene;

- the general cleanliness and hygiene of the premises, the slaughtering equipment, and the meat delivery vehicles;

- disposal of condemned meat and offal; and

- the contract management on slaughterhouse operators.

They must make regular inspections of all parts of the licensed slaughterhouses, including the slaughtering facilities, meat delivery vehicles and enforce the relevant legislation, such as the Public Health and Municipal Services Ordinance, the Food Business Regulation, the Slaughterhouses Regulation and the Prevention of Cruelty to Animal Ordinance.