Risk Assessment Studies

Report No. 21

THE MICROBIOLOGICAL QUALITY OF

EDIBLE ICE FROM ICE MANUFACTURING

PLANTS AND RETAIL BUSINESSES

IN HONG KONG

December 2005

Food and Environmental Hygiene Department

The Government of the Hong Kong Special Administrative Region

Correspondence:

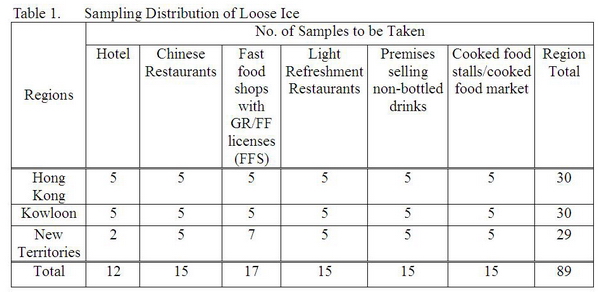

Risk Assessment Section

Food and Environmental Hygiene Department

43/F, Queensway Government Offices,

66 Queensway, Hong Kong

Email: enquiries@fehd.gov.hk

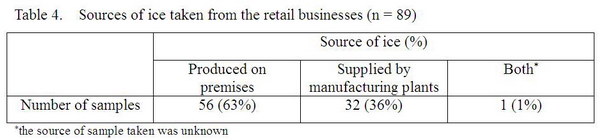

| Table of Contents |

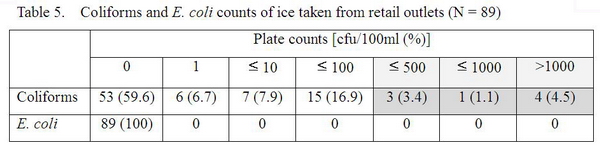

|---|

| Abstract |

| Objectives |

| Introduction |

| Scope of Study |

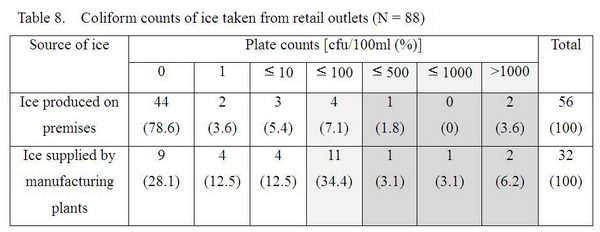

| Methodology |

| Results |

| Discussion |

| Conclusion |

| References |

| Annex : Guidelines on Hygienic Production and Handling of Ice in Food Premises |

Abstract

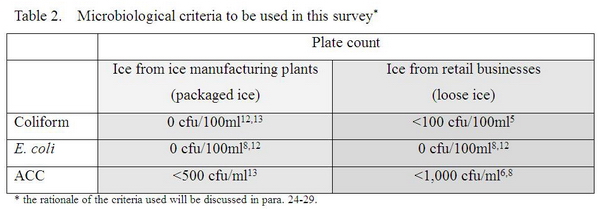

A survey was undertaken to assess the microbiological quality of edible ice from ice manufacturing plants and retail businesses (e.g. hotels, Chinese restaurants, fast food shops, etc.) in Hong Kong. A total of 89 samples from retail businesses and 12 samples from ice manufacturing plants were analysed for aerobic colony counts (ACC), coliforms and E. coli. E. coli, the indicator organism for faecal contamination, was not detected in all samples. All the 12 samples taken directly from the ice manufacturing plants met the microbiological criteria used in the study. Of the 89 samples from retail businesses, 8 (9%) and 3 (3%) samples exceeded the criteria for coliform (i.e. < 100 cfu per 100ml) and ACC (i.e. <1,000 cfu per ml) used in this study respectively. Coliform and ACC are indicators for hygienic practices and do not represent food hazard directly. In the retail sector, ice can be produced on premises or supplied by manufacturing plants. Although packaged ice sampled from manufacturing plants was shown to have satisfactory quality, significantly higher percentages of those sourced from manufacturing plants but sampled from retail outlets had higher coliform counts and ACC. The reason for this phenomenon might be that the surface of ice bags had been contaminated during transportation and storage. The contaminated surface might subsequently contaminate the ice during opening and emptying of the ice bags. Overall, this survey showed that the microbiological quality of ice samples was satisfactory and the likelihood of enteric infection through the consumption of ice from food retail businesses was low. Recommendations and advice were given to food premises on the improvement of hygienic quality of ice intended for human consumption.

OBJECTIVES

The purpose of the study is to determine the microbiological quality of edible ice from ice manufacturing plants and retail outlets. The results will provide scientific information to assess the risk of edible ice to public health and to assist in developing hygienic handling guidelines on ice for retail businesses and in making management decision on the way forward for the control of production and handling of edible ice.

INTRODUCTION

2. Ice is sometimes contaminated with pathogenic microorganisms where a contaminated water source is used in its production or where there are lapses in hygiene in their handling. Outbreaks of gastroenteritis due to contaminated ice have been reported[1] [2] [3] in other parts of the world. The possible causes of these outbreaks were due to the consumption of ice contaminated with pathogens such as Norovirus and Giardia lamblia. Investigation revealed that a server's hands might have contaminated ice machines with Norovirus[2] and there was direct transfer from the hands of a Giardia lamblia carrier who scooped up ice for restaurant customers with her contaminated bare hands[3]. Recently, a major outbreak of hepatitis A in Lampang and Chiang Rai, Thailand, affecting about nine hundred people, was also reportedly due to contaminated ice[4]. Initial investigations pointed to an ice factory in Chiang Rai Province which drew its water from contaminated artesian wells.

3. Studies from many countries have shown that the microbiological quality of ice manufactured for use in foods and drinks could be a cause for concern[5] [6] [7] [8] [9]. These studies showed that E. coli, coliforms and a variety of microorganisms could be present in ice demonstrating either the poor quality of source water used or a lack of hygiene in production or handling or both.

4. If the quality of source water is not good, harmful microorganisms may be present and the process of freezing cannot destroy them. In fact many microorganisms can survive in ice, although their numbers reduce gradually with time. When ice is thawed the microorganisms remaining may be injured, but they tend to recover their viability so that when the ice melts into drinks, they may be able to survive there too. This means that if harmful microorganisms are present in the source water from which the ice is made, they may also be viable in the ice when it is used, and capable of causing infection in the customer.

5. Equally, microorganisms contaminating ice through poor hygiene practices or by other means can survive in thawing ice too and thus also represent a risk to the consumer. In short, potable water supply, good hygiene and good handling practices are all prerequisites to the production of good quality ice.

SCOPE OF STUDY

6. Target samples were those which were likely to be used in food in retail businesses such as cold drinks for human consumption. Some samples were also taken directly from ice manufacturing plants so as to obtain baseline data on the microbiological quality of packaged ice supplying retail businesses.

METHODOLOGY

Sampling

7. The sampling period was between April and June 2005.

8. A total of 101 ice samples were collected from different locations:

(a) 89 samples from various retail outlets; and

(b) 12 samples from ice manufacturing plants.

9. Ice (i.e. packaged ice) from ice manufacturing plants was sampled directly from an intact pack. As for retail businesses, ice (i.e. loose ice) was taken directly from ice buckets or containers used for holding or storing edible ice temporarily. The ice sample was transferred to a 500 ml sampling bottle provided by Public Health Laboratory Centre (PHLC) of the Department of Health for sampling purpose.

10. Six major ice manufacturing plants were reportedly operating in Hong Kong and they were located in Kowloon (KLN) and New Territories (NT) regions. Two samples (one taken in April and another in May to ensure the samples were from different lots) were taken from each of these manufacturing plants. For the rest of the samples, Food Inspectors of Hong Kong (HK), KLN and NT regions took about 30 samples from each region from the following categories of retail businesses:

- Hotels (H);

- Chinese restaurants (CR);

- Fast food shops with General Restaurant/Food Factory licenses (FFS);

- Light refreshment restaurants (LRR);

- Premises selling non-bottled drinks (NBD); and

- Cooked food/market stalls (CFS).

During sampling, Food Inspectors also noted down the source of loose ice (i.e. whether the ice was produced on premises or supplied by ice manufacturing plants) and observed any handling practices that might compromise the microbiological quality the ice. The sampling distribution among these categories is outlined in Table 1.

Laboratory analysis

11. All samples were kept at 4oC or below during transport and delivered to PHLC within 4 hours of sampling for microbiological analyses.

12. The analyses included quantitative analysis of aerobic colony count (ACC), total coliform count and E. coli count.

Result analysis

13. Data on the microbiological quality of edible ice samples were analysed by the Risk Assessment Section of the Food and Environmental Hygiene Department. The microbiological quality of the ice was assessed against the criteria used in this study as listed in Table 2 (the rationale of using the criteria will be discussed in para. 24-29.):

RESULTS

Ice manufacturing plants

14. A total of 12 samples were taken from 6 ice manufacturing plants. Coliforms and E. coli were not detected in these samples. As regards ACC, only half of the samples had positive ACC with counts <10 cfu per ml (Table 3). The counts of these samples were 1, 1, 2, 2, 3 and 4 cfu per ml respectively.

Retail outlets

15. Eighty-nine samples were taken from various retail businesses (i.e. hotels, Chinese restaurants, fast food shops, light refreshment restaurants, premises selling non-bottled drinks, cooked food/market stalls). Among which 56 (63%) were reported to be produced on premises and 32 (36%) were supplied by ice manufacturing plants (Table 4). One sample had an unknown source because the premises produced ice on premises and, where necessary, also obtained ice from a manufacturing plant.

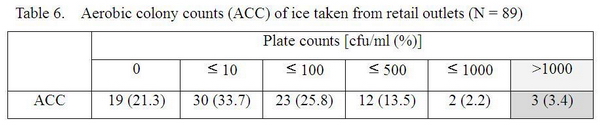

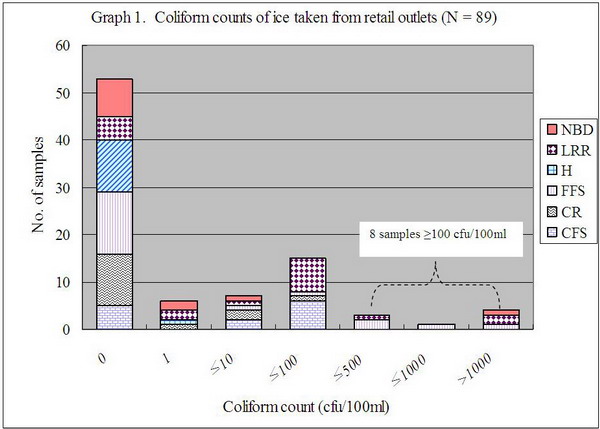

16. The indicator organisms and ACC results are shown in Tables 5 and 6 respectively. E. coli was not found in all the ice samples. While 53 (60%) samples contained no coliforms, 8 (9%) contained coliforms  100 cfu per 100ml (Table 5). The counts of these 8 samples were 130, 390, 400, 560, 1 200, 1 700, 2 300 and 9 600 cfu per 100ml respectively.

100 cfu per 100ml (Table 5). The counts of these 8 samples were 130, 390, 400, 560, 1 200, 1 700, 2 300 and 9 600 cfu per 100ml respectively.

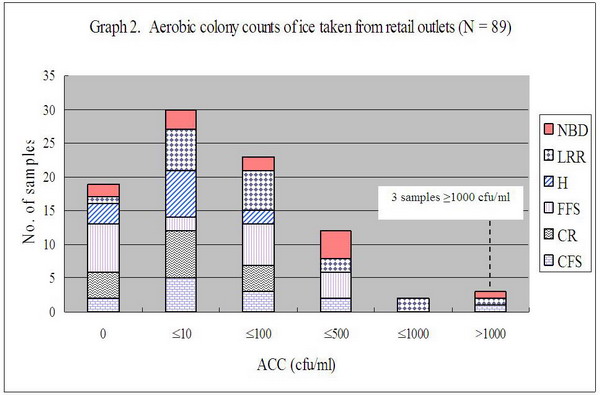

17. Only 3 (3%) samples had ACC  1,000 cfu per ml. The counts of these samples were 1 400, 1 900 and 2 500 cfu per ml respectively. (Table 6)

1,000 cfu per ml. The counts of these samples were 1 400, 1 900 and 2 500 cfu per ml respectively. (Table 6)

Types of retail businesses versus ice quality

18. Graphs 1 shows the distribution of coliform counts among different types of retail businesses. Coliforms at levels greater than 100 cfu per 100ml were found more frequently in samples taken from fast food shops (FFS), light refreshment restaurants (LRR) and premises selling non-bottled drinks (NBD). The coliform counts (in cfu per 100ml) of these samples were:-

- 130, 390, 560 and 2 300 in FFS;

- 400, 1 700 and 9 600 in LRR; and

- 1 200 in NBD.

19. Graph 2 shows the distribution of ACC among different types of retail business. Three samples taken from CFS, LRR and NBD respectively had ACC at levels >1 000 cfu per ml, with plate counts being 1 400, 1 900 and 2 500 cfu per ml respectively. Although there are differences in the ACC or coliform counts among different types of businesses, it may not be meaningful to compare them statistically due to the relatively small sample size.

Sources of ice versus ice quality

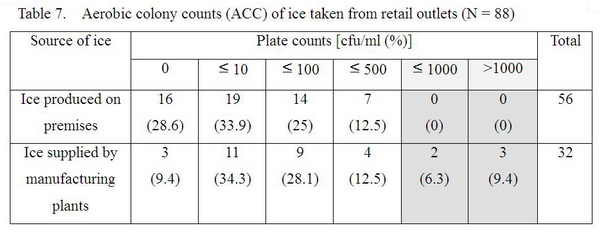

20. Fifty-six samples taken from the retail outlets were produced on premises (i.e. loose ice) while another 32 were supplied by manufacturing plants (i.e. packaged ice). Among those produced on premises, all had ACC  500 cfu per ml. However, those supplied by manufacturing plants had 5 samples with ACC >500 cfu per ml (Table 7). The differences in ACC between loose ice and packaged ice are statistically significant (χ2 = 9.28, df = 1, p < 0.05 and χ2 = 5.44, df = 1, p < 0.05 respectively).

500 cfu per ml. However, those supplied by manufacturing plants had 5 samples with ACC >500 cfu per ml (Table 7). The differences in ACC between loose ice and packaged ice are statistically significant (χ2 = 9.28, df = 1, p < 0.05 and χ2 = 5.44, df = 1, p < 0.05 respectively).

21. As regards coliform in ice samples, among the 56 samples produced on premises, 7 (13%) had coliform count >10 cfu per 100ml, whereas among the 32 samples supplied by manufacturing plants, 15 (47%) had coliform count >10 cfu per 100ml (Table 8). The difference between the two groups is statistically significant (χ2 = 12.83, df = 1, p <0.05).

DISCUSSION

Indicators

22. The three microbiological parameters examined in this survey reflect different aspects of the hygiene of ice used in retail businesses. E. coli is commonly found in the gastrointestinal tract and faeces of human beings. Its presence provides direct evidence of faecal contamination, probably resulting from handling of the ice or from serving utensils.

23. The presence of high coliform and ACC counts in ice is an indication of unsanitary conditions or poor hygiene practices during or after production. Testing for total coliform or ACC is not intended to detect faecal contamination, but rather to reflect general hygiene during production or handling of ice and the quality of the measures used to minimise bacterial contamination.

Guidelines on microbiological quality of ice

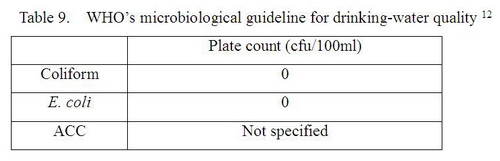

24. In many previous studies on the quality of ice[5] [10] [11], microbiological criteria for drinking water, similar to those recommended by World Health Organization[12], were usually applied (Table 9). This is because many countries do not have specific national microbiological guidelines for ice.

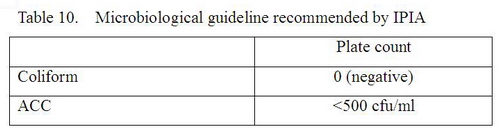

25. In the United States, the International Packaged Ice Association (IPIA) produced guidelines[13] for the industry aiming at assuring the microbiological quality of packaged ice. These guidelines require that ice must not contain coliforms and ACC <500 cfu per ml. (Table 10)

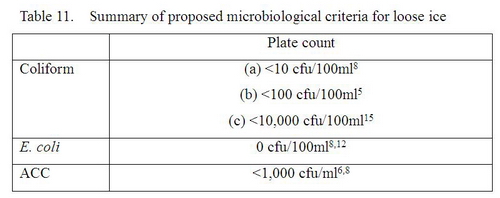

26. The use of the above microbiological criteria for all types of edible ice has been criticised by some authors[6] [8] as too stringent and unrealistic, resulting in high failure rate of ice sampled in the market. The authors commented that these criteria were too idealistic for loose ice sitting in a bucket (i.e. ice already undergone a handling process) and exposing to airborne and environmental contamination. They proposed that loose ice used to cool drinks should be of a microbiological quality at least as good as that for ready-to-eat foods stated in the Guidelines for the microbiological quality of some ready-to-eat foods sampled at the point of sale established by Public Health Laboratory Service (PHLS)[14] of the United Kingdom. Their proposed criteria, together with others, are summerised in Table 11.

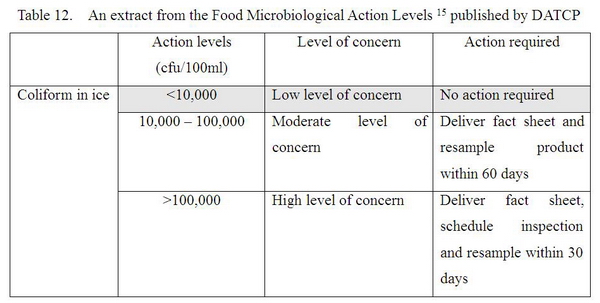

27. The Department of Agriculture, Trade and Consumer Protection (DATCP) of the State of Wisconsin, the United States is the only governmental authority found during our review to have action levels[15] specific for coliform content of ice. No action is recommended for ice sample with coliform count <10 000 cfu per 100 ml (Table 12).

28. After reviewing the previous studies on the quality of ice and taking the authors' opinions into consideration, two microbiological criteria are used for studying the quality of the ice in the current study. Table 2 lists the criteria for packaged ice sampling directly from ice manufacturing plants. The criteria combine WHO's coliforms and E. coli guidelines in drinking-water with IPIA's microbiological guidelines in packaged ice. Packaged ice from manufacturing plants is expected to have a better quality than loose ice because they are protected from the airborne and environmental contamination by a plastic bag.

29. Table 2 also lists the criteria for loose ice sampled from various retail outlets. These samples of ice are either produced on premises or supplied by manufacturing plants (in the form of packaged ice) and unpacked by the premises. The ice is therefore subject to airborne and environmental contamination. The criteria for loose ice at retail outlets in Table 2 therefore is a balance of bacterial counts which generally can be achieved through good hygiene practices against those which indicate unacceptable risk.

Ice samples from manufacturing plants

30. All samples from manufacturing plants conformed to the criteria in Table 2 (i.e. 0 cfu/100ml for E. coli and coliform and <500 cfu/ml for ACC). Although limited by the small sampling size, there is no evidence that packaged ice supplied by manufacturing plants is of unsatisfactory microbiological quality.

Retail businesses

31. Ice used for human consumption in retail outlets is of two major sources: ice supplied by manufacturing plants in a packaged form or produced on premises by food businesses themselves.

32. The satisfactory quality of packaged ice supplied by manufacturing plants has already been mentioned. As regards ice produced on premises, a good quality water supply is a prerequisite to the production of good quality ice. In Hong Kong, the public mains water is supplied by the Water Supplies Department and the quality of the water conforms to the Guidelines for Drinking-water Quality recommended by the WHO[12] (i.e. E. coli and coliforms are absent in 100 ml of water sample).

33. Because provision of public mains water is a standard licensing requirement stipulated by the Food and Environmental Hygiene Department, it is reasonable to believe that the source of water for producing ice on premises is primarily from the tap and this guarantees the microbiological quality of the source water.

34. The results showed that no E. coli was detected in the ice samples taken from retail businesses, suggesting that the likelihood of enteric infection through consumption of loose ice is low.

35. The results also showed that there were some 9% (8 out of 89 samples) and 3% (3 out of 89 samples) of the samples did not conform to the coliform and ACC levels listed in Table 2 (i.e. coliform < 100 cfu per100ml and ACC <1,000 cfu per ml respectively). Of the retail businesses, the ice sampled from hotels and Chinese restaurants seems to have a better quality than that from the other groups. However, the sampling size of each group is too small to give a statistically significant conclusion.

36. Ice samples from retail businesses that sourced from manufacturing plants had significantly higher percentages of samples with coliform counts >10 cfu per 100ml and ACC >500 cfu per ml. Since packaged ice from manufacturing plants was shown to have a satisfactory microbiological quality, the findings of significant higher counts in ACC and coliform in ice originating from manufacturing plants reflect certain underlying causes, during the handling of packaged ice, that may be conducive to post-production contamination.

37. The most probable causes of the contamination of packaged ice in retail businesses are:-

- unhygienic handling, during transport, of packaged ice resulting in the contamination of the external surface of a ice bag;

- unhygienic storage of packaged ice in food premises resulting in contamination of the surface of a ice bag;

- cross-contamination from the surface of a ice bag to ice when transferring ice from the ice bag to an ice bucket.

38. Although not common, Food Inspectors, during sampling, also found the following handling activities that might compromise the microbiological quality of ice. These included:-

- ice bucket did not have a cover;

- food handler forgot to cover the ice bucket after scooping; and

- handles of serving utensils were too short and hands touched the ice during scooping.

39. Authors in other similar studies also discovered some malpractices that may also be associated with poor quality of ice. These factors include :

- ice-making machines were located in neglected areas of premises which might receive less regular cleaning[8];

- staff were not adequately trained or motivated in the cleaning and maintenance of ice-making machines[8]

- food handlers, without washing their hands properly, contaminated ice-producing machines with pathogens[2] [3],

- melt water was present in ice buckets, indicating that the ice buckets were filled repeatedly without being cleaned[6]

- equipment such as ice buckets and scoop were infrequently cleaned[6]

- bare hands touched the ice.

CONCLUSION

40. This study found that all the ice samples taken from the manufacturing plants satisfied with the criteria for total coliforms and E. coli (absence in 100ml) as specified in the WHO drinking water guideline.

41. As regards ice taken from retail businesses, E. coli was not detected in all the samples, implying that the likelihood of enteric infection from the consumption of ice is low. A small proportion of samples did not satisfy our suggested criteria with respect to total coliform and ACC. That is, 9% and 3% of samples from retail outlets did not satisfy the criteria for total coliform (100 cfu/100ml) and ACC (1 000 cfu/ml). Ice samples sourcing from manufacturing plants had a significantly higher ACC and coliform counts. Contamination of external surface of ice bags during transport and storage as well as contamination of ice during opening and unpacking of the ice bags are the most probable causes for the findings.

42. Potable water supply, good handling and good hygiene practices are prerequisites to the production of good quality ice. The Food and Environmental Hygiene Department has developed "Guidelines on Hygienic Production and Handling of Ice in Food Premises" (Annex) for retail food businesses producing and handling ice for human consumption.

Risk Assessment Section

Food and Public Health Branch

December 2005

REFERENCES

- Pedalino, B., Feely, E., McKeown, P., Foley, B., Smyth, B., and Moren, A. An outbreak of Norwalk-like viral gastroenteritis in holidaymakers travelling to Andorra, January-February 2002. European Communicable Disease Bulletin 2003; Vol. 8 No. 1

- Khan, A.S., Moe, C.L., Glass, R.I., Monroe, S.S., Estes, M.K., Chapman, L.E., Jiang, X., Humphrey, C., Pon, E., Iskander, J.K. and Schonberger, L.B. Norwalk virus-associated gastroenteritis traced to ice consumption aboard a cruise ship in Hawaii: comparison and application of molecular method-based assays. Journal of Clinical Microbiology 1994; 32(2), 318-322.

- Quick, R., Paugh, K., Aldiss, D., Kobayashi, J. and Baron, R. Restaurant associated outbreak of Giardiasis. Journal of Infectious Diseases 1992; 166(3), 673-676.

- APEC-EINet. Thailand: Embargo on ice production after hepatitis outbreak. APEC 2005

Available from: http://depts.washington.edu/einet/?a=printArticle&print=483 - Anonymous. 2002. Microbiological Quality of Ice for Cooling Drinks. Food Safety Authority of Ireland

Available from: http://www.fsai.ie/surveillance/food/ice_cooling_drinks.pdf - Nichols, G., Gillespie, I, deLouvois, J. The Microbiological Quality of Ice Used to Cool Drinks and Ready-to-Eat from Retail and Catering Premises in the United Kingdom. J.Food Prot. 2000; 63: 78-82.

- Vieira, R.H.S.F., de Souza, O.V. and Patel, T.R., 1997 Bacteriological Quality of Ice used in Mucuripe Market, Fortaleza, Brazil. Food Control 1997; 8(2): 83-85.

- Wilson, I.G., Hogg, G.M. and Barr, J.G. Microbiological Quality of Ice in Hospital and Community. J. Hospital Infect. 1997; 36:171-180.

- Moyer, N.P., Breuer, G.M., Hall, N.H., Kempf, J.L., Friell, L.A., Ronald, G.W. and Hausler, W.J. Quality of Packaged Ice Purchased at Retail Establishments in Iowa. J Food Prot. 1993; 56: 426-431.

- Falcao, J.P., Dias, A.M.G., Correa, E.F. and Falcao, D.P. Microbiological Quality of Ice Used to Refrigerate Foods. Food Microbiology 2002; 19:269-276.

- Schmidt, R.H., Rodrick, G.E. Microbial, Physical and Chemical Quality of Packaged Ice in Florida. J. Food Prot. 1999; 62:526-531.

- WHO Guidelines for Drinking-water Quality, Vol. 1. (3rd ed.) 2004

Available from: http://www.who.int/water_sanitation_health/dwq/GDWQ2004web.pdf - International Packaged Ice Association

Available from: http://www.packagedice.com/ - PHLS. Guidelines for the microbiological quality of some ready-to-eat foods sampled at the point of sale. Communicable Disease and Public Health 2000; 3:163-167

- State of Wisconsin, Food Microbiological Action Levels 2002.

Available from:

http://datcp.state.wi.us/fs/business/food/publications/pdf/microfactsheets/dfs-3052Microbioactionlevelstable.pdf

Annex

Guidelines on Hygienic Production and Handling of Ice in Food Premises

(These Guidelines apply to ice intended for human consumption)

Ice is widely used in food premises for a number of reasons. Normally ice is either made by machines on premises (generally as ice cubes or ice flakes) or supplied by a specialist supplier (as packaged ice).

If not properly handled, ice can be a vehicle of spreading foodborne diseases. It is the responsibility of the management of a food premises to ensure that sufficient instruction and training are given to employees on good hygiene practice in order to minimise the potential for contamination of ice.

(A) Mode of ice production

(i) Packaged ice

Source

Packaged ice intended for human consumption should be obtained from reliable and reputable suppliers.

Transport and storage

Packaged ice should be transported and stored in a hygienic manner so as to minimise contamination of the external surface of the package.

Re-filling ice buckets

Ice should be handled hygienically when being transferred from the package into ice buckets:-

- clean ice buckets and the surrounding surfaces before loosening packaged ice;

- clean and dry the surface of packages with a clean cloth before re-filling ice buckets;

- use clean utensils to open ice packages; and

- external surface of packages and bare hands should not touch the ice.

(ii) Ice produced on premises

Source

The ice machine should be connected to a mains water supply to ensure that ice is not made from water already contaminated by microorganisms.

Machine Location

The machine should be sited in an area away from potential sources of contamination.

Machine Servicing

The machine should be serviced in accordance with manufacturer's instructions. Most machines require servicing at least twice a year.

Machine Cleaning

- The ice storage compartment should be cleaned regularly (e.g. daily according to the instructions of the manufacturer) to prevent the build up of bacteria.

- The ice that has been removed from the machines to allow for cleaning should be disposed of and it should not be returned to the ice machine.

- The exterior of the machine particularly the door/hatch of the ice storage compartment should be cleaned on a regular basis.

(B) Handling, Storage and Service of Ice

- The person dispensing ice from the machine or the storage bin should wash and dry their hands thoroughly before starting the task.

- The ice should always be removed from the machine using a clean utensil such as a scoop (hand should never be used). Do not use breakable utensils such as a drinking glass to dispense ice.

- Scoops and other utensils in contact with the ice should be cleaned at the end of every working day. This equipment should be checked throughout the day for any sign of contamination, and cleaning should take place when necessary.

- Ice buckets should be cleaned at the end of each day and any ice remaining in ice buckets should be disposed of. After cleaning, ice should not be returned to the ice buckets.

- The handle of the scoop should not come into contact with the ice. The scoop should be positioned in such a way that staff does not touch the ice when taking hold of the handle.

- Ice storage bins and ice buckets should always be kept covered.

- Ice storage utensils should not be used for the cooling/storage of other items (e.g. bottles of beer, cans of soft drinks or cartons of milk).

Risk Assessment Section

Food and Public Health Branch

December 2005