Introduction

According to the Frozen Confections Regulation (Cap. 132AC), frozen confection means any confection commonly sold for human consumption in a frozen or chilled state. Some examples are ice-cream (including hard ice-cream and soft ice-cream sale for serving in retail outlets, as well as pre-packaged ice-cream in original cups and wrappers), frozen yoghurt and sundae.

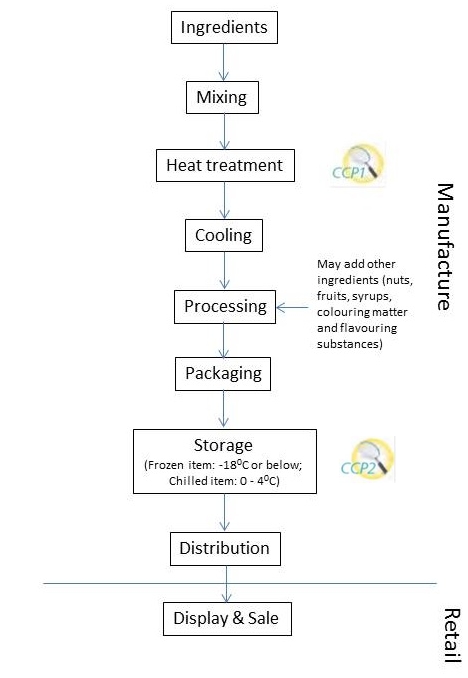

Flow Diagram for the Manufacture and Sale of Frozen Confections

Figure 1 shows a general schematic for the process of manufacture and sale of frozen confections:

In the manufacture of frozen confection, heat treatment, most commonly pasteurisation, is applied to minimise microbiological hazards. During heat treatment, the mixture of ingredients is heated for a prescribed temperature and time.1 As a result, pathogens and spoilage microorganisms can be effectively reduced without causing undesirable changes to taste, texture or appearance of the food.

The products should be kept at low temperature after heat treatment to prevent microbial growth at the subsequent storage. Rapid cooling following heat treatment is required to minimise the duration that the product is being held within the danger zone (4-60oC), at which microorganisms could grow rapidly.

After heat treatment, contamination by microorganisms in the environment or other ingredients is possible at any point during processing, packaging, storage, delivery and retailing. Therefore, the manufacturer should apply appropriate preventive measure to ensure their products are not contaminated with microorganisms. Good temperature control is essential along the whole process (include receiving, processing, storage, transport, distribution and retailing) for maintaining the safety and quality of frozen confections.

Key Points to Note

- Heat treatment is the Critical Control Point (CCP) to reduce the number of microorganisms in frozen confections.

- Improper storage temperature could lead to unsatisfactory microbiological quality of the frozen confections. Storage of frozen confections is also a CCP.

- Contaminated ingredients (e.g. nuts and flavouring materials contaminated with microorganisms) added after the heat treatment could introduce microorganisms to the frozen confections.

1 The conditions of heat treatment as stipulated in Cap. 132AC Frozen Confections Regulation are (a) at 66 degrees Celsius for not less than 30 minutes; or (b) the mixture shall be raised to and kept at a temperature of not less than 71 degrees Celsius for not less than 10 minutes; or (c) the mixture shall be raised to and kept at a temperature of not less than 79 degrees Celsius for not less than 15 seconds.

Food Safety Advice for Manufacture and Sale of Frozen Confections

Ingredients and Processing

-

Obtain ingredients from reliable sources and store ingredients at proper temperature:

- Frozen item: -18oC or below;

- Chilled item: 0-4oC.

-

Inspect ingredients and documents before acceptance to ensure that:

- There is no sign or indication of contamination or damage to ingredients;

- Chilled/ frozen ingredients have arrived at proper storage temperatures (e.g. frozen items: at -18oC or below; chilled item: at 0-4oC) and are free from observable evidence of temperature abuse.

-

Use the ingredients before their expiry dates and follow the first-in-first-out principle.

-

Keep documentation of ingredients for traceback purposes.

-

Proper documentation and monitoring system should be in place to ensure that the heat treatment steps are properly carried out.

-

In case ice-cream is produced by freezing of ice-cream pre-mix, without heat treatment process, only pasteurised pre-mix should be used. Trader should clarify with the supplier and ensure that the ice-cream pre-mix has been subjected to heat treatment.

-

After the mixture has been subjected to heat-treatment, it shall be reduced to a temperature of not more than 7oC within one and a half hours and shall be kept at a temperature lower than 7oC until frozen.

-

Ingredients (e.g. nuts, fruits, syrups, colouring matter and flavouring materials) added after the heat treatment should be properly treated (e.g. heat treatment) to prevent the contamination of the product.

-

All equipment (e.g. ice-cream making machine and different tanks) should be cleaned and disinfected thoroughly before and after use, according to the manufacturer instruction.

-

For situation that air is incorporated into the product, it may be a source of microbial and foreign matter contamination. It should be of good quality and filtered.

Packaging, Storage and Distribution

-

Store final products at proper temperature:

- Frozen item: -18oC or below;

- Chilled item: 0-4oC.

-

Check the temperature of refrigerators, freezers and soft ice-cream dispensing machines regularly.

-

Maintain a first-in-first-out principle to avoid prolonged storage which affects the freshness and safety of frozen confections.

-

Single-use containers for the frozen confections and other utensils liable to come into direct contact with the frozen confections should be stored in lidded containers or sealed plastic bags to avoid contamination and should be disinfected, if necessary, before use.

Display and Sale

-

Discard the defrosted ice-cream products and do not re-freeze melted products.

-

For soft ice-cream: drain off and discard the leftover of soft ice-cream in the dispensing machines daily. The dispensing machine should be thoroughly cleaned and subsequently sterilised with steam or clean boiling water every day before and after use, according to the manufacturer instruction. Cleaning process of the dispensing machine should be properly recorded.

-

Newly opened or freshly prepared frozen confections should not be mixed with the leftover of the previous batch.

-

Arrange regular inspection, maintenance and repair of soft ice-cream dispensing machine with the manufacturer.

-

For food display and selling, frozen confections should be placed in well-maintained, clean and hygienic refrigerator and freezer equipped with thermometer.

-

Clean, disinfect or replace ice-cream scoops regularly.

Environmental Hygiene

-

Defrost the refrigerator and freezer regularly to maintain the correct temperature.

-

Use approved disinfectants to clean and sanitise the refrigerator and freezer regularly according to the manufacturer instruction, and maintain a documented cleaning schedule.

-

All utensils and equipment that come in contact with food (e.g. strainers, mixing bowls and stirrers) should be cleaned and disinfected thoroughly before and after use. Replace damaged and cracked utensils.

-

All work surfaces should be impervious. All utensils should be easy to clean and kept away from the ground. Clean overhead structures as often as necessary and prevent condensation dripping on the product.

- Use covered rubbish bins, and empty and disinfect them regularly.

Personal Hygiene

-

Wash hand thoroughly with soap and water before and after handling food.

-

Wear clean clothing.

-

Cover open wounds and septic sores on hands and arm with water-proof dressings.

-

Stop handling food if suffering from sore throat or gastrointestinal disturbances, like diarrhoea and vomiting.

-

Wear gloves and use clean and disinfected utensils when handling food. Change gloves frequently, discard gloves after use and never reuse gloves.

Food Safety Management

-

Establish and maintain a preventive food safety management system to ensure that effective control measures are in place.

-

Provide regular training to food handlers on the operation of equipment (include cleaning of soft ice-cream dispensing machine) and hygienic practices.

-

Carefully plan the preparation schedule and do not entertain orders beyond the production capacity of the manufacturing factory.

-

Traders are reminded to comply with the requirements in manufacturing of frozen confections as stipulated in the Frozen Confections Regulation (Cap. 132AC).