Food Safety Focus (230th Issue, Sep 2025) – Article 1

Prepackaged Cold Cuts to be Eaten Cold or Cooked?

Reported by Dr. Violette LIN and Dr. Ken CHONG, Scientific Officers

Risk Assessment Section, Centre for Food Safety

Prepackaged cold cuts contaminated with bacteria leading to food recalls is a known and concerning practice globally. This July, a salami (Salmonella-contaminated) and a turkey bacon (Listeria monocytogenes- contaminated) were imported but were later recalled under the instructions of the Centre for Food Safety. These cold cuts can be kept in the refrigerator for use within a certain period of time. Some cold cuts are ready-to- eat (RTE), while some require further cooking. So how long can they be stored? Do we need to cook them? This article will discuss these questions and illustrate how to use their food labels in making informed choices.

What are cold cuts?

Cold cuts (aka deli meats, cold meats, etc.) are usually precooked and/or cured meats that are served cold, while they also include cured meats that require further cooking. Curing is the addition of appropriate amounts of salt and nitrates/nitrites among other substances to raw or cooked meat for preservation, colour and flavour enhancement. They started as a way to survive food shortages, then transitioned into a popular and premium delicacy enjoyed by nobles and later by everyone. While curing extends the shelf life of cold cuts, they are perishable (i.e. need to be kept under refrigeration), and those RTE ones (i.e. further cooking is not necessary before consumption) are high-risk foods. They are vulnerable to contamination from production facilities to our homes if traders and consumers mishandle or improperly store them.

The shelf life of cold cuts is controlled by multiple “hurdles”

Heating is one preservation method in making cold cuts from raw meat and other methods (e.g. smoking, drying, curing, vacuum packaging, and fermentation) have been used in combination to extend the shelf life of these products. These create inhibitory factors (“hurdles”) that are unfavourable environments for microbial growth. Table 1 shows some of these factors which can be included in the Hazard Analysis and Critical Control Point (HACCP) plan in the cold cuts manufacturing processes.

Table 1: Examples of hurdles for slowing microbial growth in cold cuts

| Hurdles | Examples |

| Physical |

|

| Chemical |

|

The growth of bacteria including the pathogenic bacteria on cold cuts is determined by a number of physical factors such as temperature, salt content, water activity (aw) (i.e. water available for microbial growth), pH and so on. Each type of bacteria has an optimum temperature, salt content, aw and pH for growth. For example, Listeria monocytogenes grows from pH 4.4 to 9.4, while the growth rate would be reduced under conditions close to the extremes of the pH range. Each factor, if not at optimum, can be a hurdle to microbial growth, and hurdles originating from different factors can be combined for retarding microbial growth. For cured meat, salt reduces the aw in meat to about 0.98 to 0.96 which helps to slow bacterial growth. The addition of the preservative nitrite also inhibits microbial growth as well as producing the pink colour in cured meat.

Storing and handling cold cuts according to the instructions on the food label

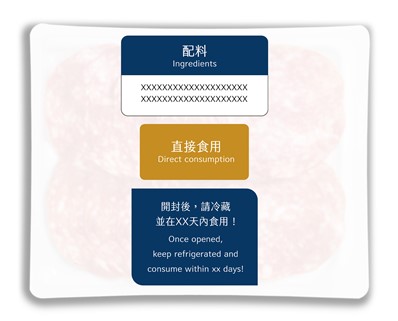

Despite the presence of hurdles to microbial growth, cold cuts have a defined shelf life. In addition, mishandling by consumers, e.g. extended storage after opening, may create microbiological risks. Thus, manufacturers should convey important food safety messages for consumers on the food labels (Figure 1), for instance:

- recommendations on further heat treatment; and

- storing instructions (e.g. temperature and duration) for unopened (the use-by date) and the remaining product (e.g. use within certain days).

Apart from adhering to the label instructions, consumers should not eat the product if any of the spoilage signs are present (e.g. mould, slimy texture and foul smell). Moreover, susceptible populations should avoid cold cuts or reheat them before eating.

Key Points to Note

- Prepackaged cold cuts are usually prepared by cooking and curing raw meat which are high-risk foods, and heat treatments may be needed for some.

- Cold cuts are perishable. Refrigerate them properly to prevent bacterial growth.

- Handle cold cuts according to the food label instructions.

Advice to the Trade

- Source cold cuts from reliable suppliers.

-

Keep cold cuts under refrigeration and monitor the temperature of storage, transportation, and

display of these products.

- Provide storage conditions and instructions for use on prepackaged cold cuts for consumers to handle the products safely.

Advice to the Public

- Read the food label for the storage directions and handling instructions.

- Consume the prepackaged cold cuts as soon as possible and finish any refrigerated remaining products before the recommended duration.

- Susceptible populations should avoid cold cuts. If necessary, reheat them before consumption.

Figure 1: Examples of food labels showing the storage and usage instructions for cold cuts