Feature Article

Siu Mei and Food Safety

In June 2023, the Centre for Food Safety (CFS) investigated a series of food poisoning cases involving siu mei. The affected persons presented with gastrointestinal (GI) symptoms including abdominal pain, diarrhoea and vomiting. The incriminated food items were siu mei dishes and the causative agent was suspected to be Salmonella. Hygiene and food handling deficiencies, including preparation of siu mei too far in advance, prolonged storage in the temperature danger zone, inadequate cooking temperatures and cross-contamination with raw food, were detected in the siu mei kitchen in question.

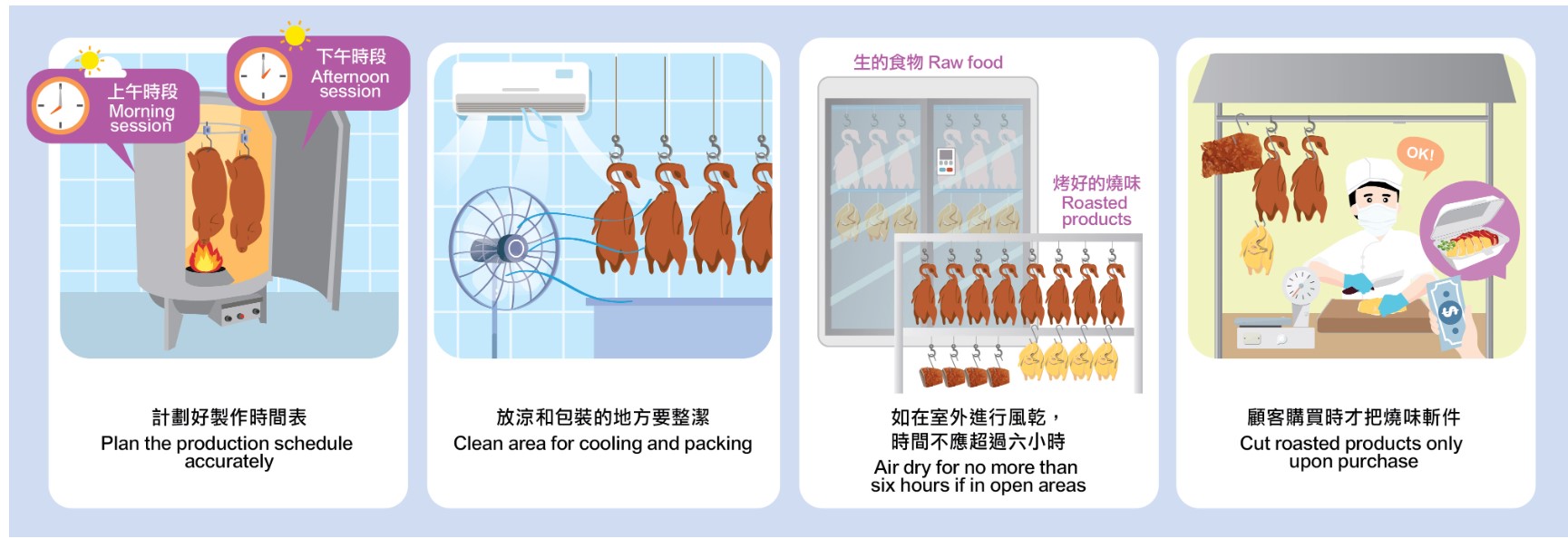

Good practices in preparing and selling siu mei

Common Pathogens in Siu Mei

Salmonella and Staphylococcus aureus were implicated in past siu mei food poisoning outbreaks. Salmonella causes GI illnesses within 6 to 72 hours after oral exposure, with symptoms such as nausea, vomiting, abdominal cramps, diarrhoea, fever and headache. While the infection is usually self-limiting in healthy individuals, it may be lethal to susceptible populations. Salmonella can be found in contaminated water, soil, food contact surfaces and hands, and in the GI tracts of animals and humans. It is spread mainly through the faecal-oral route and contaminated water. The process of slaughtering can also cause contamination of meat.

On the other hand, S.aureus, commonly found in the hairs, skin, nasal cavity, throat and wounds of humans, can contaminate food through food handlers’ hands, especially after cooking. For food involving post-cooking cutting and prolonged storage at room temperature, S.aureus can grow exponentially and form heat-stable toxins.

Antimicrobial Resistance (AMR) Bacteria

AMR bacteria are not necessarily pathogens and can be commensal bacteria that derive benefits from their association with humans. Similar to other environmental organisms or commensal bacteria in humans, AMR bacteria can contaminate food if food and hand hygiene is neglected. Although AMR infections can be asymptomatic, microorganisms can still gain resistance spontaneously by gene mutation or gene transfer among each other. The strategies provided in the “Five Keys to Food Safety” for preventing foodborne diseases can also effectively reduce the risk of AMR infections.

Addressing Food Safety Issues Related to Siu Mei

Although pathogens can be easily killed by thorough cooking, some common malpractices can lead to contamination of siu mei.

-

Unhygienic air drying process, where siu mei can become contaminated due to dirty environment or prolonged drying time;

-

Contamination due to poor protection of siu mei after cooking and during subsequent handling, including display, cutting and transportation;

-

Dirty equipment and poor personal hygiene;

-

Cross-contamination by raw or partially cooked food;

-

Prolonged display of cooked siu mei due to over-production.

Food Safety Measures for Production of Siu Mei

Production

Plan the production schedule accurately ahead of time to avoid over-production and prolonged storage of cooked siu mei at room temperature. Arrange for two or more sessions of roasting daily to cater for the demand during peak hours at lunch and dinner, thereby minimising the storage time. Defrost frozen meat in a refrigerator at 4℃ or below or under running water. Do not defrost the frozen meat at room temperature.

Post-production Handling

Designate a clean area away from raw food for cooling and packing cooked siu mei with dedicated tools to prevent cross-contamination. Keep the area clean. Vehicles for transporting siu mei should not have been previously used for transporting raw food or chemicals to prevent contamination. Cover the siu mei while leaving adequate room to avoid moisture build-up.

Display and Sale

Minimise the display time with accurate production planning. Display siu mei in insect-proof and dust-proof showcases, in which no raw food should be stored. Avoid stacking of siu mei. Follow the “2-hour / 4-hour” rule for display of siu mei at room temperature. Cut roasted siu mei only upon purchase. Roasted products, especially pre-packaged ones, kept in the temperature danger zone should preferably be sold within two hours after chopping.

Key Points to Note:

- Pathogens such as Salmonella and aureus can be present in meat and meat products as many animals harbour them naturally;

- Thorough cooking of food can kill many pathogens and AMR bacteria;

- Proper planning, production and handling of siu mei, as well as maintenance of personal and environmental hygiene can prevent microbiological contamination.

Advice to the Trade

- With proper planning, production and handling as well as maintenance of hygiene, the chance of pathogen contamination can be minimised. For details, please refer to the CFS's Siu Mei – Food Safety Guidelines for Food Businesses.

English

English

Mascot ON in Lesson

Sapovirus – Pathogenic Virus Similar to Norovirus

In a recent local food poisoning case involving raw oysters, Sapovirus was detected in the stool samples of an affected consumer and a food handler who handled the oysters. Sapovirus taxonomically belongs to the same family as Norovirus. Both viruses can cause acute gastroenteritis and the clinical symptoms caused are indistinguishable. This article tells you more about sapoviruses in food and the preventive measures.

Sapovirus

Sapovirus, previously known as “Sapporo-like virus”, was named after an outbreak of acute infectious diarrhoea that occurred in an orphanage in Sapporo, Japan in 1977. Gastroenteritis outbreaks associated with sapoviruses are less common than those caused by noroviruses both globally and locally. According to a review by the Centre for Health Protection, among the 182 outbreaks of acute gastroenteritis voluntarily reported by institutions and schools in 2017, only two (1.1%) involved sapoviruses.

Similar to noroviruses, sapoviruses are primarily transmitted through the faecal-oral route and person-to-person contact (e.g. contact with faeces, vomitus or contaminated materials/surfaces) or via contaminated food and drinking water. Outbreaks in institutional settings are therefore not uncommon. Although dose-response study for sapoviruses is currently not available, it is believed that their infectious dose is low, comparable to that of noroviruses.

Gastroenteritis Caused by Sapoviruses

Sapovirus gastroenteritis symptoms are usually self-limiting and patients usually recover within a couple of days. The symptoms, severity and duration of the disease depend on one's health status. Symptoms include diarrhoea and vomiting, nausea, stomach/abdominal cramps, chills, headache, myalgia or malaise. The incubation period ranges from less than one day to four days. Sapoviruses shedding in faeces may continue after symptoms disappear.

Sapovirus gastroenteritis occurs throughout the year in people of all ages, while sporadic cases mainly take place in the cold season. In addition, sapovirus cases appear to be more common in younger children than in adults and older children. On the other hand, sapovirus-related gastroenteritis outbreaks have been reported in various settings such as child care centres, kindergartens, nursing homes and schools, where susceptible individuals gathered and person-to-person transmission was likely involved.

Sapoviruses in Foods

Sapoviruses may be present in shellfish or water environment as a result of human faeces discharged to the environment. Oysters and clams as well as river water and wastewater have been detected with sapoviruses that are genetically indistinguishable from those clinical isolates. It is believed that sapoviruses can be spread by contaminated shellfish in a way similar to noroviruses. Hence, the preventive measures for noroviruses are also applicable to sapoviruses.

Since oysters feed by filtering a large amount of water through their gills, they are susceptible to contamination if grown in contaminated waters. To reduce the risk of contracting sapoviruses, oysters and other bivalves should be cooked thoroughly until the core temperature reaches 90°C for 90 seconds. The following are some suggested cooking time for different preparation methods:

- Boil for 3 to 5 minutes at 100°C

- Fry for at least 3 minutes at 190°C

- Steam for 4 to 9 minutes at 100°C

- Bake for at least 10 minutes at 230°C

Susceptible populations (the elderly, young children, pregnant women and people with weakened immunity) should avoid eating raw oysters.

As food handlers can also be a source of contamination, it is very important for them to maintain personal hygiene. They should wash their hands thoroughly with clean running water and soap for 20 seconds after using the toilet and before handling food. If they have symptoms of vomiting or diarrhoea, they should not handle food until they are symptom-free for at least two days and should seek medical advice.

Figure 1: Given the high risk of pathogenic contamination for raw oysters, food handlers should adopt corresponding food safety measures.

Securing Food Safety during Adverse Weather and Extreme Conditions

Hong Kong often experiences adverse weather and extreme conditions caused by tropical cyclones and storm surges, which could result in flooding and power outages, especially during summer. While members of the public may stock up on food in preparation for such emergencies, flooding and power outages could expose food to improper storage conditions, causing spoilage and contamination of food. This article discusses the strategy to make preparations for food storage and highlights the steps for securing food safety when facing flooding and power outages.

Plan Wisely and Store Suitable Amount of Food

Some people may consider buying and storing food beyond their need before the advent of adverse weather and extreme conditions. It is essential to store food properly to avoid spoilage and it is preferable to buy only the quantity needed. Before you go shopping for food, keep a running list of meals and their ingredients and reserve sufficient storage capacity. Do not buy food that is near or past its expiry date.

After shopping, keep the food according to storage instructions, for example keep the food refrigerated at ≤4°C or frozen at ≤-18°C. Cooked and perishable foods (for example fresh meat and poultry, aquatic products and milk) should be refrigerated within two hours. To prevent contact between raw food and ready-to-eat or cooked food, they should be stored separately in covered or sealed containers. Do not overload the refrigerator so as to maintain good circulation of cold air. Non-perishable food items should be kept in a cool and dry place.

Salvage Food after Floods – Safe or Not?

All perishable food that has not been refrigerated or frozen properly due to power outages should be discarded. During flooding, food may be immersed in floodwater. Floodwater may contain pathogens and can contaminate food. It is therefore important not to eat any food that has been immersed in floodwater and has not been packaged in a waterproof container. All non-prepackaged food items and those without waterproof packaging that have been immersed in floodwater should be discarded. Only commercially manufactured metal cans with double-seamed lids and retort pouches are regarded as waterproof food packaging. Food with such packaging may be salvageable after thorough washing, sanitising and labelling. Any food with an unusual odour, colour or texture should be thrown away.

Examples of food items eligible and not eligible for food salvage

How to Wash and Disinfect Utensils after Flooding?

For those containers and dishware made of waterproof materials that may have come into contact with food, they can be reused after thorough washing and sanitising. Take metal pans and ceramic dishes for example. Simply wash them with soap and water and then rinse. Sanitise the cleaned utensils by boiling them in clean water or immersing them in 1:99 diluted household liquid bleach for 15 minutes, and then allow them to air dry. Wooden and plastic utensils like cutting boards should be discarded if they have been immersed in floodwater as they cannot be safely cleaned.

Keeping Food Safe during a Power Outage

Most refrigerators and freezers do not have backup power supply. When electricity is cut off, cold air will stop circulating, which could expose food to unsafe temperatures. Keeping frozen gel packs, ice cubes and dry ice in refrigerators before a power outage can help store food at safe temperatures for a longer period of time. It is advisable to keep a thermometer in the refrigerator to indicate the temperature, which helps determine afterwards whether the foods stored are still safe to eat. When a thermometer is not available, we can still determine whether the foods stored are still safe by keeping track of the downtime. Keeping refrigerator and freezer doors closed can maintain cold temperature. If the doors have not been opened, the food stored will stay safe for 2 to 4 hours in the chiller, 24 hours in a half-full freezer and 48 hours in a full freezer.

When the power returns, check the temperature of the refrigerator and the freezer to see whether perishable foods like fresh meat and poultry have been exposed to the temperature danger zone (i.e. between 4°C and 60°C). For high-risk food that has been kept within the temperature danger zone, follow the “2-hour/4-hour rule”. Some frozen foods may still contain ice crystals, they are safe to be refrozen or cooked. However, ice-cream should be discarded even if it feels cold as if refrigerated. Never taste foods to determine whether they are safe to eat, as they might not give off an abnormal taste or odour even if they are spoiled.

Tips on food safety before the advent of adverse weather and extreme conditions, after flooding and after electric outages

Securing food safety during adverse weather and extreme conditions is essential. In addition to making preparations for food reserve, the trade and the public should be well-prepared for flooding and power outages. Food business operators should ensure that food is fit for human consumption and discard spoiled food. The public should carefully identify food items eligible for recovery and salvage them properly before consumption.

Spot Check

Ensuring Food Safety: Proper Cooling, Defrosting and Reheating

The risk of food poisoning increases in summer as warmer weather accelerates the growth of bacteria. Proper temperature control throughout all stages of food preparation, including cooling, defrosting and reheating, is essential for preventing food poisoning. In this article, we will explain important food safety concepts that food businesses should pay special attention to, including the temperature danger zone, proper cooling techniques, as well as key points on defrosting and reheating.

What is the Temperature Danger Zone?

The temperature danger zone refers to the temperature range where bacteria can rapidly multiply in food and thus increase the risk of foodborne illnesses. It typically ranges from 4℃ to 60℃. Harmful bacteria can grow in food left at dangerous temperatures, and sometimes can produce heat-resistant toxins, which cannot be destroyed even by reheating. Therefore, it is crucial to minimise the time that food is exposed to the temperature danger zone to prevent bacterial multiplication, spore germination and the formation of heat-resistant toxins that can cause foodborne illnesses. Cooling food quickly and storing it at proper temperatures after cooling can reduce food safety risk.

Cooling Food – Best to Make it Fast

Prepared food that will not be consumed immediately should be cooled properly. Proper cooling can reduce the time that food is exposed to the temperature danger zone, and thus lower the risk of bacterial growth. In general, a two-step cooling approach can be used for cooling food. First, cool the food from its cooking temperature to 20℃ within two hours. Then, cool it further from 20℃ to 4℃ in a refrigerator within the next four hours (Figure 2). To speed up the cooling process, it is desirable to cut the food into smaller pieces or spread it out in shallow covered containers, and place them in a well-ventilated area.

Some food business operators may use specialised equipment such as blast chillers to quickly cool hot food to a safe temperature at 4℃ or below within 1.5 hours, which further shortens the time of food being exposed to the temperature danger zone. When blast chilling is done, the food should be stored in refrigerators or freezers.

Figure 2: Two-step cooling approach and techniques of speeding up cooling

Defrosting – Better to Thaw Food at Safe Temperatures

Even if food is frozen at 0℃ or below, some harmful bacteria present in the food may still be alive but just inactive. Once frozen food is thawed, its core temperature will rise and bacteria may start to be active again and multiply. Therefore, proper food defrosting is crucial for preventing the growth of harmful bacteria.

Proper food defrosting can be achieved by using a refrigerator set between 0℃ and 4℃, running cold tap water or a microwave oven. To keep food safe, it is preferable to defrost frozen food in a refrigerator. For food that needs refreezing, it should be defrosted in a refrigerator, which allows the food to be kept out of the temperature danger zone throughout defrosting. Do not defrost food at room temperature, as this exposes the food to dangerous temperatures for an extended period of time, promoting bacterial growth.

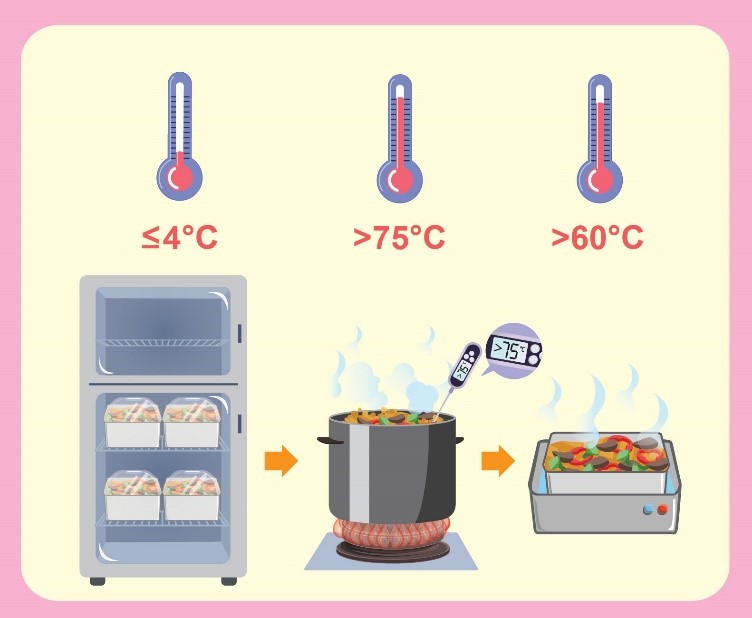

Reheating – Key to Secure Food Safety Before Consumption

Reheating precooked food means cooking again, not just warming up. When reheating, like cooking, ensure that the core temperature of the food reaches at least 75℃ for 30 seconds and then serve it at a proper hot holding temperature at above 60℃ (Figure 3). Avoid refrigerating reheated food because bacteria can grow if it stays at dangerous temperatures for too long. Of note, do not heat food using bain maries or other devices designed solely for keeping food hot. This may take too long or fail to heat the food adequately to keep it safe.

Figure 3: Reheating and serving food at proper temperatures

Proper temperature control throughout all stages of food preparation is fundamental to ensuring food safety. Effective cooling, defrosting and reheating procedures are essential for minimising the risk of foodborne illnesses. Proper record keeping for temperature monitoring at each stage is also important as it ensures that food is prepared at safe temperatures and helps evaluate the performance of hot-holding and chilling equipment, which are vital for maintaining food safety standards. Equally important is the provision of comprehensive training to staff, equipping them with the necessary knowledge and techniques relevant to their specific roles. Ongoing training plays a pivotal role in staff’s skill development in respect of safe handling of food.

Safe Kitchen/Trade Talks/Food Safety Guidelines

Safe Kitchen

Introduction to “Safe Kitchen” Scheme

To facilitate the adoption of the “5 Keys to Food Safety” and Good Hygiene Practices (GHPs) by trade members, and ensure food safety in their daily operation, the CFS has integrated the existing channels of risk communication and launched a new platform, namely “Safe Kitchen”, to communicate with the trade. The platform provides food safety information of greater practical importance to meet the operational needs of catering outlets.

The “Safe Kitchen” platform disseminates up-to-date food safety information (including food safety guidelines and relevant legislative amendments) to the trade through a host of channels including WhatsApp, emails and dedicated websites. In response to food poisoning outbreaks in restaurants, the platform will also issue food alerts to remind the trade of the points to note in preventing future occurrences so that the risk of food poisoning can be minimised.

New dedicated websites and risk information exchange platforms will be rolled out under the “Safe Kitchen” Scheme. In addition, training materials tailor-made for the trade and workshops for kitchen staff will be provided to enhance food safety and hygiene awareness among them. Members of the trade are welcome to scan the QR code to download the registration form for the “Safe Kitchen” Scheme in order to receive the latest food safety information in a timely manner.

Trade Talks

Trade Talks 2024

The CFS will organise food safety talks and workshops on GHPs for Food 2024 from March through October to publicise proper food handling to employees of food businesses, with a view to promoting GHPs for Food through active participation from the trade and its collaboration with the government, and encouraging the development of a Food Safety Plan in food processing, thereby enhancing food safety.

The talks will be conducted in Cantonese. Participants will be awarded a certificate of attendance. Details can be found under “What's New” on the CFS's website.

https://shorturl.at/txBOU

Food Safety Guidelines:

Oysters Intended for Raw Consumption - Food Safety Guidelines for Food Businesses

As oysters and other shellfish are filter-feeders that concentrate microorganisms in sea-water, they are easily contaminated by viruses (e.g. Hepatitis A and Norwalk-like viruses). Consumption of undercooked oysters contaminated with viruses may result in illness caused by viral infection.

Ensuring food safety relies on tripartite collaboration among the food trade, the general public and the government. It is incumbent on the food trade to ensure food for sale is fit for consumption. To ensure consumers’ food safety, food handlers should always stay vigilant. In the preparation of oysters (e.g. deep-fried oysters, braised oysters with ginger and spring onion, and braised oysters with port), food handlers should observe environmental and utensil hygiene, and keep in mind the food safety risks and precautions.

In view of this, the CFS published a pamphlet, namely “Oysters Intended for Raw Consumption - Food Safety Guidelines for Food Businesses”, which covers the trade’s GHPs in sourcing, receiving, storing, preparing and delivering raw oysters for reducing risks of contamination. The pamphlet also provides safe ways to cook oysters.

Members of the trade can browse or download the guidelines by clicking the following link or scanning the QR code next to it.

News on CFS

1. CFS's Press Briefing for Announcing Risk Assessment Study Results on Industrially Produced Trans Fatty Acids Content in Prepackaged and Non-Prepackaged Food

The CFS announced on 9 November 2023 the results of a risk assessment study on industrially produced trans fatty acids (IP-TFA) content in prepackaged and non-prepackaged food. The CFS collected 149 samples from five food categories, namely fats and oils, margarines and spreads, prepackaged foods, ready-to-eat foods and miscellaneous local specialities for IP-TFA content analysis. Results revealed that the levels of IP-TFA in 143 out of the 149 samples were below the World Health Organization (WHO) guidance level of 2 grams per 100 grams total fat, while six samples contained IP-TFA higher than the WHO guidance level.

For details of the study report, please visit the following webpage or scan the relevant QR code:

https://www.cfs.gov.hk/english/programme/programme_rafs/programme_rafs_n_01_32_IpTFA_Content_in_Prepackaged_and_Non_prepackaged_Food.html

The press briefing is hosted by Dr. Sze Kwan Lok, Chemist (Risk Assessment) (left), Dr. Cheung Yung Yan, Consultant (Community Medicine) (Risk Assessment & Communication) (middle) and Mr. Hung Chi Tat, Senior Chemist (Risk Assessment) (right).

2. Talk on the Daya Bay Contingency Plan Held by CFS

The CFS jointly organised an annual talk on the Daya Bay Contingency Plan with relevant government departments (including the DH, the Electrical and Mechanical Services Department and the Food and Environmental Hygiene Department (FEHD)) on 23 November 2023. On the day of the talk, departmental representatives took turns to share on topics relating to their respective scope of work, such as nuclear power generation, radiation monitoring, radiation exposure pathways, surveillance of imported food, management of contaminants and wastes, radiation devices, and protective equipment monitoring, so as to update our colleagues on the contingency plan.

3. Briefing for Students of Bachelor Programmes, Chinese University of Hong Kong (CUHK)

Like previous years, the CFS held a briefing for students of Bachelor of Science in Community Health Practice and Public Health programmes, Faculty of Medicine, CUHK on 4 December 2023 to give information on the role of the FEHD in food safety surveillance and control in Hong Kong so that the students can have a preliminary understanding of the work of the CFS, thereby facilitating their career planning for professional development.

4. Food Safety Seminar for Trade 2023 Held by CFS

On 7 December 2023, the CFS held the Food Safety Seminar for Trade 2023, which aimed to provide an opportunity for the Government and food trade to exchange information and views on current and important food safety issues in Hong Kong, and encourage continuous improvement and collaboration in securing food safety among the local food trade.

Dr. Wong Wang, Controller, CFS officiates and delivers an opening address at the Food Safety Seminar for Trade 2023.

The seminar, held at Charles K. Kao Auditorium, Hong Kong Science Park, consisted of four sessions, namely Expert Sharing, Control Measures and System Implementation, Legislation and Guidelines, and Producing Safe and Healthy Food & Food Safety Promotion. The seminar was divided into the morning and the afternoon parts, with question and answer sessions for the trade representatives to ask questions.

For details of the event, please visit:

https://www.cfs.gov.hk/english/whatsnew/whatsnew_act/Food_Safety_Seminar_for_Trade_2023.html

5. The 83rd Meeting of the Trade Consultation Forum

The 83rd meeting of the Trade Consultation Forum was held on 20 December 2023. The CFS and the trade exchanged their views on various topics including “Food Safety Advice for Handling Ready-to-eat Food”, “Risk Assessment (RA) Study on IP-TFA Content in Prepackaged and Non-Prepackaged Food”, “RA Study on Partially Hydrogenated Oils (PHOs) in Food”, “RA Study on Sodium Content in Chinese Congee”, “Further Advice for Food Traders on Importing Japanese Food”, and “Fee Adjustment for Food Inspection Certificate and Health Certificate for Foods of Animal Origin”. For details of the event, please visit:

https://www.cfs.gov.hk/english/committee/Notes_and_Presentation_Materials_TCF83_20231220.html

6. Promotion of Food Safety by CFS at the 57th Hong Kong Brands and Products Expo

The annual Hong Kong Brands and Products Expo is one of the major outdoor trade fairs in Hong Kong. The 57th Expo was held at Victoria Park starting from late December 2023. Same as previous years, the CFS joined the Expo to disseminate food safety messages to the public. For two consecutive days on 3 and 4 January 2024, the CFS set up a booth in the Expo to distribute publicity leaflets, pamphlets and souvenirs to visitors to promote food safety. The booth was bustling with visitors.

Ask Our Mascots

Soufflé Pancakes and Salmonella

In mid-August last year, the CFS conducted an investigation of suspected food poisoning cases related to the consumption of soufflé pancakes from a local restaurant. The investigation revealed the causative pathogen was likely Salmonella. The investigation also found irregularities in the preparation process of soufflé pancakes, namely improper storage temperature of pooled eggs, baking temperature of the soufflé pancakes not properly monitored and the use of unpasteurised whole shell eggs.

Potential Risk of Consuming Undercooked Egg Dishes

Eggs can be contaminated by Salmonella during their formation. If they are stored improperly, Salmonella will proliferate. Salmonella can also survive in undercooked foods, which pose a very high risk of food safety as inadequate heat treatment cannot eliminate pathogens completely and may cause food poisoning upon consumption. Besides Salmonella, undercooked egg dishes may also contain bacteria with antimicrobial resistance (AMR).

How to Store Egg Ingredients and Prepare Soufflé Pancakes Safely?

Field investigation by the CFS found that the storage temperature of raw pooled eggs in the restaurant concerned was above 10°C, which was within the temperature danger zone (i.e. between 4°C and 60°C). Storing food at temperatures within the temperature danger zone allows various types of bacteria to grow rapidly. Dried egg powder, once opened, should be stored in airtight containers placed in a cool and dry place. Refrigerators should include temperature displays, which should be constantly monitored and reported at least twice a day. If any deviations higher than 1°C are identified, checking of the devices is warranted. In addition, following the first-in-first-out (FIFO) principle for the use of egg ingredients is essential to keeping egg dishes safe. Unused egg products in the refrigerator should be stored in covered containers separately to avoid cross-contamination.

Lack of proper monitoring of the baking temperature of soufflé pancakes may explain the survival of harmful pathogens like Salmonella in this case. To prevent food poisoning, it is advisable to cook egg dishes thoroughly until the core temperature reaches 75°C or above, or the whole egg products are firm. Prolonged storage of cooked egg products at room temperature is also a common cause of food poisoning. Therefore, it is important to store hot dishes at above 60°C and cold dishes at 4°C or below, and plan ahead to avoid preparing them too far in advance.

Use Pasteurised Egg Products Wisely

Choosing safe egg ingredients is the crucial step to ensure food safety. Pasteurised shell or liquid eggs are recommended as the pasteurisation process involves heating eggs to a specific temperature for a set time, aiming to prevent spoilage and extend their shelf-life. It can reduce the risk of foodborne illness, especially when preparing egg dishes that are not intended to be cooked thoroughly for achieving the required texture. The occurrence of recent food poisoning cases related to egg products clearly illustrates the risk of using unpasteurised whole shell eggs for preparing these types of egg dishes. If pasteurised egg products are to be used later, store them in sealed containers in the refrigerator and only take out the amount required. Use all of them on the same day and do not top up with new batches of pasteurised egg products.

Key Points to Note:

- Undercooked egg dishes may contain pathogens like Salmonella and AMR strains that could lead to food poisoning and AMR transmission respectively upon consumption.

- Store egg ingredients properly and bake egg dishes thoroughly.

- Use pasteurised egg ingredients to prepare egg dishes that are not intended to be cooked thoroughly, and observe Good Hygiene Practices (GHPs).

Advice to the Trade

- Avoid preparing egg products too far in advance

- Refrigerate egg ingredients at 4°C or below

- Monitor the storage and cooking temperatures of egg ingredients and dishes

- Observe GHPs

Enhancement Quiz

- Which of the following will lead to contamination of siu mei?

- Unhygienic air-drying process, i.e. dirty environment or prolonged drying time

- Poor protection of siu mei after cooking and during subsequent handling, including display, cutting and transportation

- Cross-contamination by raw or partially-cooked food

- Prolonged display of cooked siu mei due to over-production

- All of the above

- The following are the suggested temperatures and time for preparing oysters. Which one is incorrect?

- Boil for 3 to 5 minutes at 100°C

- Fry for at least 3 minutes at 190°C

- Steam for 4 to 9 minutes at 100°C

- Bake for at least 3 minutes at 230°C

- Which pathogen can contaminate eggs during egg formation?

- Sapovirus

- Ciguatoxin

- Salmonella

- Norovirus

Answers:

Diary of Mascot ON

Say No to Cross-Contamination!

Becoming the greatest sword master in the world is not only a promise to my peers, but also a commitment to protect everyone against cross-contamination between raw and cooked food.

Spreading Pathogens and Superbugs

If food is handled improperly, for example, purge and juices from the raw meat or seafood dripping onto ready-to-eat food, or ready-to-eat food being handled with hands, utensils and worktops that have been in contact with raw meat and seafood without proper cleaning beforehand, the food will be contaminated with pathogens or even “superbugs”, which have resistance. This may result in food poisoning, and even cause “superbugs” to spread through food!

Tips on Preventing Cross-Contamination

However, my own power is limited and may not be able to safeguard everyone. Therefore, I have decided to pass on to all of you my unique and exquisite skills in food safety.

- Keep hands clean: Wash hands thoroughly with liquid soap after touching raw food and right before handling cooked and ready-to-eat food, such as sandwiches, siu mei, lo mei.

- Separate raw and cooked food: Place food in the fridge by following the rule of “cooked food at the top, raw food at the bottom”.

- Use separate utensils to handle raw and cooked food: Apply the “Three Swords Skill” by using separate knives to handle raw and cooked food.

- Keep the kitchen clean: Wash utensils and worktops with hot water and detergent before and after handling food each time.

Remember, maintain a strict control on food safety to protect yourself and the people around you.