Report No. 12

Chemical Hazard Evaluation

Acrylamide in Fried Fritters

December 2003

Food and Environmental Hygiene Department

The Government of the Hong Kong Special Administrative Region

This is a publication of the Food and Public Health Branch of the Food and Environmental Hygiene Department of the Government of Hong Kong Special Administration Region. Under no circumstances should the research data contained herein be reproduced, reviewed,or abstracted in part or in whole, or in conjunction with other publications or research work unless a written permission is obtained from the Department. Acknowledgement is required if other parts of this publication are used.

Correspondence:

Risk Assessment Section

Foodand Environmental Hygiene Department

43/F,Queensway Government Offices,

66Queensway, HongKong.

Email:enquiries@fehd.gov.hk

Table of Contents

Conclusions and Recommendations

Abstract

Acrylamide formation during deep-frying of a wheat flour-based Chinese traditional food, fried fritters(油條), was studied. Samples of fried fritters were prepared under different combinations of frying temperature and frying time, with frying temperature set at 170°C, 190°C and 210°C and frying time ranged from 3 to 18 minutes at each temperature setting respectively. The degree of browning and the texture of the finished products were recorded as quality parameters. Results showed that the level of acrylamide increased with frying time at all three temperatures, and if the frying time was held constant, the level was higher if higher frying temperature was used. Fried fritters cooked at lower temperatures and longer frying time could produce products with lower levels of acrylamide without any change in organoleptic quality when compared with those products that are produced by higher temperatures and shorter frying time. The study showed that the critical points in minimizing the formation of acrylamide in foods were the control of cooking temperature and cooking time.

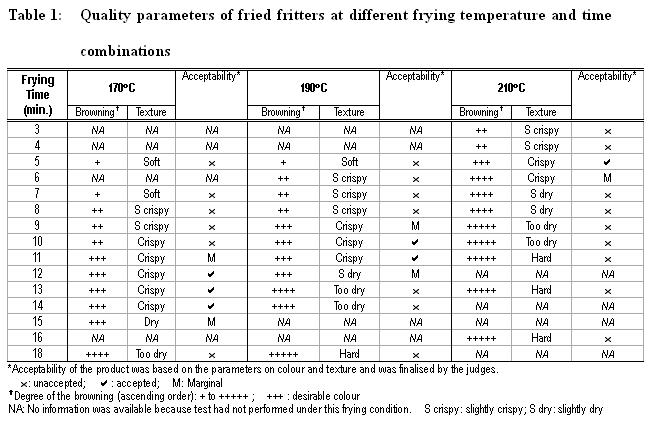

Risk Assessment Studies -

Acrylamide in Fried Fritters

Study on the effect of temperature and time of deep frying on the formation of acrylamide in Fried Fritters

BACKGROUND

Introduction

1. The Food and Environmental Hygiene Department (FEHD) analysed some 450 food samples for their acrylamide content in 2002 and 2003. Findings of the study were in line with those released by overseas food authorities and acrylamide was detected in a variety of common fried and baked foods such as chips (French fries), potato crisps, breakfast cereals, cookies, as well as Chinese style food items such as fried dumplings and fried fritter. Cooking temperature, length of heating, degree of dryness and composition of the ingredients seem to play a role alongside other possible factors.

2. To complement studies conducted by overseas food authorities which mainly involve Western foods like potato chips, FEHD has initiated a specific study on the effects of variation of frying temperature and frying time on the formation of acrylamide for a common traditional Chinese food, namely fried fritter (油條).

Fried Fritters

3. Fried fritter is one of the traditional Chinese foods. Its origin is lost in antiquity and could date back to Sung Dynasty (i.e. A.D. 960-1279). Fried fritter requires deep-frying in its preparation. Unlike fritters of Western style, the Chinese fried fritter has no stuffing. The combination of its slightly savory taste and crispy texture provide a unique sensation when freshly fried. Fried fritter is often served with congee in breakfast in the local diet.

Preparation of fried fritters

4. The basic ingredients include wheat flour, water, salt and yeast. To prepare a fried fritter, the ingredients are evenly mixed with water until the dough holds its shape and the dough is rolled until it became smooth and elastic. The dough is allowed to rest for 2-3 hours for fermentation. The dough is then divided into portions and each portion is rolled out before cutting into strips. Two strips are then stacked up, stretched to a desired length (approx. 25 cm) and deep-fried. Deep-frying, usually operates at 170 - 210°C for 5 - 12 minutes, transforms the strips into light crispy fritters.

Health implications of acrylamide

5. Acrylamide is a chemical that has long been used to make polyacrylamide materials which have a variety of industrial uses e.g. treatment of drinking water and waste water, manufacturing of plastics, paper and cosmetics, etc. The main health concerns regarding acrylamide are on its potential to cause cancer in humans and its toxic effects on the nervous system. In its evaluation on acrylamide, the International Agency on Research of Cancer (IARC) classified acrylamide in Group 2A (probably carcinogenic to humans) based on that there is sufficient evidence of carcinogenicity in experimental animals but inadequate evidence of carcinogenicity in human. The World Health Organization (WHO) Consultation panel in June 2002 reaffirmed this IARC conclusion. [1] Concerning its adverse effects on the nervous system, acute toxicity is rare but acrylamide has been found to cause nerve damage in people who have long term exposure to high doses at work. The WHO has established a "No Observed Adverse Effect Level" (NOAEL) of 0.5mg (or 500µg) per kg body weight per day for acrylamide with respect to its effects on the nervous system.

Heating process and formation of acrylamide in food

6. In general, foods rich in carbohydrate and prepared at temperature above 160°C exhibit acrylamide formation and this may be related to the degree of browning. [2] Browning is a result of a series of reactions known as Maillard reaction. Maillard reaction, apart from providing desirable colour, contributes to the flavour and aroma of the final product.

7. Studies conducted so far indicated that foods with high carbohydrate content such as potatoes, develop high levels of acrylamide when heated at high temperature. It has been suggested that the amino acid asparagines and reducing sugars in Maillard reaction accounted for the majority of acrylamide in potato products. [3], [4]

8. At present, the mechanisms of acrylamide formation and the pathways involved have not been fully understood. It is believed that temperature, time, moisture and pH have their roles on the formation of acrylamide during the cooking of potato products.

OBJECTIVE

9. The study aims to study the effect of temperature and time of deep frying on the formation of acrylamide in fried fritters.

SCOPE OF STUDY

10. For the purpose of this study, three temperature models are tested. Fried fritters are deep-fried for various length of time at 170°C, 190°C and 210°C respectively. These temperatures are within the normal range of temperatures required for deep-frying. Frying temperature below 170°C may not able to perform the deep-frying process, while temperature above 210°C is considered too high at which smoking of oil appears.

METHODS

Preparation of samples

11. The preparation of fried fritters for the study was conducted in the training centre of a restaurant chain. A piece of 5-kilograms of dough was prepared from wheat flour, water, yeast, baking soda and salt, and set for about three hours. To ensure the consistency of raw materials for each temperature models, the piece of fermented dough was divided into three equal portions. The portions were rolled out and cut into 15 cm-strips of equal size. Two strips were stacked up and stretched to about 25cm long. About 15 of stacked strips were prepared for each temperature model.

Frying temperature and duration

12. Vegetable oil was used for deep-frying. The temperature of frying oil was maintained at 170+3°C and oil temperature was checked with a hand-held thermocouple probe. When the temperature was stabilized, all 15 prepared strips were deep-fried simultaneously. After a certain period of time, a piece of the fried fritter product was retrieved. It was set aside for cooling and draining away the excess oil before packing for subsequent laboratory testing.

13. The experiment was repeated at the frying temperatures of 190+3°C and 210+3°C respectively.

Acceptability of the final product

14. An "acceptable quality" of a fried fritter was judged by its appearance and texture. The fried fritters should look "golden brown" and be crispy outside and whilst the inside was soft upon completion of cooking. No under-cooked dough should be adhered onto the stick which was probed into the fried fritter. The inner structure of the fried fritter should look translucent. These parameters were assessed by a panel composed of an experienced cook, a food scientist and two chemists on-site.

Laboratory analysis

15. All fried fritters together with a piece of uncooked fermented dough were labelled and sent to the Food Research Laboratory (FRL) for acrylamide analysis. The method used was based on Liquid Chromatograph-Tandem Mass Spectrometer (LC-MS/MS) and had been validated by single-laboratory validation.

16. The fried fritter was homogenized and a representative portion (1-4 g) was tested. This portion was extracted by water and the extracts were cleaned up on various solid phase extraction columns, and subsequently tested on the LC-MS/MS. Acrylamide-1,2,3-C13 was used as an internal reference (surrogate) for the analysis. The limit of detection was 3 μg/kg.

RESULTS AND DISCUSSION

Change of colour and texture

17. Upon deep-frying, browning started to be observed on the surface of the dough. The surface of the product changed from soft to a slightly crispy crust with appreciable amount of browning after about eight minutes at 170oC, six minutes at 190oC, and less than three minutes at 210oC. Then the colour of the product darkened to golden and at the same time the crust became crispy. Extended frying resulted in dark brown, hard and dry but oily over-cooked products. Judging by the colour and texture of the product, it was found that the range of frying time for an "acceptable quality" product at 170oC was 12 to 14 minutes. When the frying temperature increased to 190°C, the range changed to 10 to 11 minutes, while at 210°C only a frying time of 5 minutes was found able to produce an "acceptable quality" product. As frying temperature increased, the frying time and the range of time for an "acceptable quality" product became shorter and narrower respectively. The quality parameters of the products fried at different temperature and time combinations are listed in Table 1.

18. Fried fritters were browned faster at higher temperature. Visually, there were differences in brownness among the fried fritters prepared at 170°C, 190°C and 210°C for the same period of time. At 170°C and 190°C, the surfaces of the fried fritters were slightly browned after 5-minute frying, whereas the sample was golden brown when fried at 210°C for 5 minutes.

Level of acrylamide

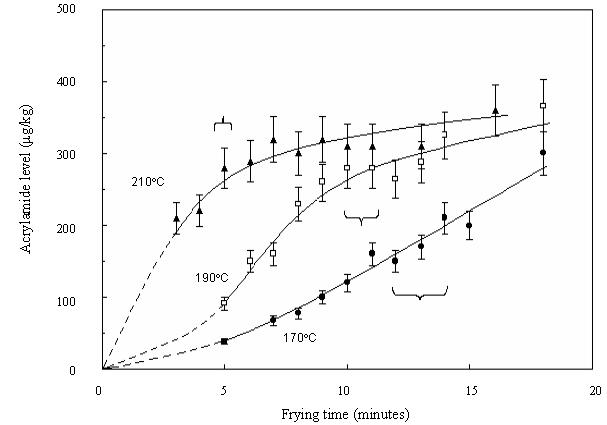

19. The data on acrylamide levels collected from various frying time at the three preset frying temperatures were summarized in Figure 1.

20. For all three models at different frying temperatures, the acrylamide levels in the samples showed a general trend of steady increase against frying time, from below detection limit in the raw dough to a levelling value of about 350 μg/kg in the over-cooked product. The increase in acrylamide at 170oC was gentle but steady throughout the 18-minute frying period. At 210oC, the acrylamide level increased very rapidly upon frying, but converged after about five minutes gradually approaching the levelling value. For the case of 190oC, the increase in acrylamide was in between the other two: a gentle initial rise to about five minutes, then a rapid increase in rate followed by converging after about 10 minutes.

Figure 1: Level of acrylamide in fried fritters prepared at different temperature and time

21. For the same frying duration, it was found that higher levels of acrylamide were detected at higher temperatures. At 5 minutes, frying at temperature of 210oC, resulted in 8 times and 3 times higher levels of acrylamide than those at 170oC & 190oC respectively.

22. Considering the judgement made by the panel on the quality of the product according to the colour and texture, the acrylamide content in the acceptable fried fritters prepared at 170oC was about 150μg/kg to 200μg/kg, while the level was above 250μg/kg for those products prepared at 190oC and 210oC respectively. Within the "acceptable quality" range, the shorter the frying time, the lower the level of acrylamide was found.

23. Formation of acrylamide in the product was affected by heating process. The reaction accounted for the formation of acrylamide was initiated on the surface of the dough by direct heat from the hot oil, while the reaction in the interior of the dough was controlled by the heat transfer process, partly through radiation/conduction and partly via diffusion of hot oil into the food matrix. At the lower temperature of 170oC, the reaction for acrylamide formation was slow. The overall formation of acrylamide, both on the surface and in the interior of the dough, was relatively controlled by the heat transfer process. This accounted for the gentle but steady rise in acrylamide content of the product. On the other hand, the reaction at 210oC proceeding rapidly on the surface that received direct heat from the oil dominated the formation of acrylamide, resulted in steep rise in the overall acrylamide content. Eventually, the formation kinetic was dominated by the slower heat transfer process. For the case of 190oC, an intermediate temperature, a short induction period was still observed for the dough to pick up the heat for initiating the reaction. Then the process proceeded as in the case for 210oC.

24. The findings are consistent with the proposal of acrylamide formation through the Maillard reaction in carbohydrate-rich food at high temperature. The reaction, as indicated by the browning of the food, was initiated mainly on the surface of the food upon deep-frying.

CONCLUSIONS AND RECOMMENDATIONS

25. This study provides useful information to understanding the formation of acrylamide in food during the deep-frying process. As illustrated in the preparation of fried fritters, the acrylamide content in the food product depended on the frying temperature and time. Both increase in frying temperature and increase in frying time resulted in higher levels of acrylamide. Deep-frying at high temperature caused rapid rise in acrylamide content of the food product.

26. While the cooking condition used in the study is not an absolute directive for the trade, it can serve as guidance in the production of fried fritter and other deep-fried products. In light of our findings, the trade is advised to observe the following in a bid to reduce the levels of acrylamide in their products. -

(a) to avoid overcooking the fried fritters with excessive high-temperature (e.g. 210°C or above);

(b) to fry fitters as briefly as possible and avoid excessive browning (i.e. only until the products are cooked through and golden brown).

(c) to avoid repeatedly frying the fried fritters and discard the left-over;

27. For the general public, it is advised to avoid eating fried foods which are over-cooked as they tend to have higher acrylamide contents. The public is also advised to have a balanced and varied diet, eat more fruits and vegetables, and should moderate consumption of fried and fatty foods.

REFERENCES

[1] WHO. Health Implications of Acrylamide in Food: Report of a Joint FAO/WHO Consultation, WHO Headquarters, Geneva, Switzerland, 25-27 June 2002. Geneva: WHO; 2002.

[2] The Joint Institute for Food Safety and Applied Nutrition (JIFSAN). Acrylamide in Food Workshop: Scientific Issues, Uncertainties and Research Strategies. Maryland: JIFSAN; 2002. [cited 2002 Nov 21] Available from: URL: http://www.jifsan.umd.edu/Acrylamide/acrylamide_workshop.html

[3] Stadler RH, Blank I, Varga N, Robert F, Hau J, Guy PA, et al. Food Chemistry: Acrylamide from Maillard reaction products. Nature 2002; 419:449 - 50.

[4] Mottram DS, Wedzicha BL et al. Food Chemistry: Acrylamide is formed in the Maillard Reaction. Nature 2002; 419: 448-9.