Contents

- Chapter 1: Introduction

- Chapter 2: What is a Food Safety Plan

- Chapter 3: How to implement a Food Safety Plan

- Stage 1: Planning

- Stage 2: Draw a flow diagram

- Stage 3: Develop a Food Safety Plan

- Step 1 List hazards

- Step 2 Identify preventive measures and their control limits

- Step 3 Establish monitoring procedures

- Step 4 Establish corrective actions

- Step 5 Keep records

- Step 6 Check and review

- Chapter 4 Basic requirements for a Food Safety Plan

- Chapter 5 Relevant websites

Chapter 1

Introduction

Recently, a number of foodborne illnesses occurred worldwide have aroused the concern and anxiety of the public about food safety. Most of these foodborne illnesses are caused by mishandling or improper preparation/ storage of food by food handlers (Appendix 1). In order to ensure food safety and prevent food poisoning, all food businesses including food service organizations should comply with the existing food regulations as well as prepare their own Food Safety Plan (FSP) based on the principles of Hazard Analysis and Critical Control Point (HACCP) system.

HACCP adopts a proactive approach to anticipate the occurrence of potential problems during the food production process and to implement measures designed to prevent the occurrence of these problems.

HACCP system has been adopted worldwide by many food manufacturing companies. However, a "classical" HACCP system is generally considered not feasible in the food service organizations due to the multiplicity of food products, lack of standardised methods, lack of systematic production planning as well as lack of expertise to develop the system. This document contains an FSP based on the principles of HACCP in order to assist managers of food service organizations to tackle the above problems and ensure food safety, including

1. an outline of the stages involved in developing an FSP;

2. a list of potential problems that may occur during food production in catering operations; and

3. a list of control measures that can be applied generally to most catering operations and advices on when and how these control measures can be applied.

Chapter 2

What is a Food Safety Plan?

An FSP is designed to identify and prevent possible food safety problems (hazards) in order to enhance food safety. The problems may relate to the purchase, receiving, storage, preparation, cooking, packaging, transport or display of food.

There are six elements in an FSP:

1. List food safety problems (hazards) at each step of the food processing (e.g. purchase and receiving of food)

2. Identify preventive measures and their control limits

3. Establish monitoring procedures

4. Establish corrective actions

5. Keep records

6. Check and review

Appropriate implementation of the above elements, together with the application of some basic practices (e.g. cleaning and sanitation, personal hygiene, pest control, waste disposal and staff training), will certainly prevent food safety problems during the food production.

Appropriate implementation of the above elements, together with the application of some basic practices (e.g. cleaning and sanitation, personal hygiene, pest control, waste disposal and staff training), will certainly prevent food safety problems during the food production.

Chapter 3

How to implement a Food Safety Plan?

Stage 1 Planning

Preliminary planning and preparation will be essential before developing your FSP. A coordinator for developing an FSP should be appointed and adequate authorities and resources should also be provided. The coordinator must have basic knowledge of food safety and must be familiar with the properties of food as well as its processing procedures.

Staff should be made aware of the changes and benefits that will result from the introduction of the FSP. The FSP will only work if each staff member knows their role in the plan, and is committed to making it work. To reduce the anxiety of staff, the FSP should be introduced in phases over a period of time. For example, the FSP could be introduced initially for just the first step of the catering operation (i.e. purchase of raw materials), making sure that the first step is working properly before moving onto the next step.

Staff should be made aware of the changes and benefits that will result from the introduction of the FSP. The FSP will only work if each staff member knows their role in the plan, and is committed to making it work. To reduce the anxiety of staff, the FSP should be introduced in phases over a period of time. For example, the FSP could be introduced initially for just the first step of the catering operation (i.e. purchase of raw materials), making sure that the first step is working properly before moving onto the next step.

Stage 2 Draw a flow diagram

A flow diagram should be drawn showing each step in the operation, from purchase of raw materials to serving food to consumers. The flow diagram shown here is a generic example for a catering operation which should be tailored to each individual operation. Each of the steps of the operation can be considered a control point to prevent food safety problems.

* Note: "Display" is applicable to businesses providing buffets.

Stage 3 Develop a Food Safety Plan

Step 1 List hazards

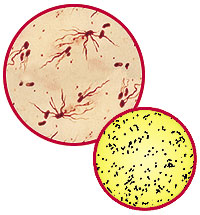

A hazard is anything that may cause a food to be unsafe for human consumption (Appendix 2). Use your flow diagram to identify all the hazards (food safety problems) associated with each step.

Examples of problems:

- Raw materials contain harmful micro-organisms (e.g. raw oysters contaminated with Norwalk-like virus and raw eggs contaminated with Salmonella)

- Harmful micro-organisms grow and produce toxin during processing

- Harmful micro-organisms or toxins survive after heating

- Food contains harmful chemicals (e.g. ciguatoxin in coral reef fish)

- Food contains extraneous physical objects (e.g. metal, glass fragments)

Of these, harmful micro-organisms as well as toxins produced by them are likely to be the most important problems that cause foodborne illnesses.

Step 2 Identify preventive measures and their control limits

List the measures and the control limits that can be used to control the identified problems (i.e. those identified at step 1) at each step of the catering operation. A control limit is a value or measurement (such as temperature or acidity) that must be met to ensure safety of the product.

Examples of preventive measures and their control limits are:

| Preventive measures | Control limits |

|---|---|

| I. Using reputable suppliers | Products bought from approved / licensed and reputable suppliers |

| II. Adequate freezing or chilling | Frozen / chilled foods should be stored at -18°C / 4°C or below |

| III. Using proper ways to thaw frozen foods |

Frozen foods should be thawed under/in

|

| IV. Cooking thoroughly | During cooking the core food temperature should reach 75°C or above for at least 30 seconds |

| V. Proper cooling | Cooked foods should be cooled from 60°C to 20°C in two hours and then to 4°C or below in the next four hours |

Step 3 Establish monitoring procedures

The monitoring of control limits will ensure that any loss of control (i.e. deviation from control limits) can be identified so that corrective actions can be taken before the product becomes unsafe. The methods used should be kept as simple as possible.

Examples of monitoring procedures include:

- Cooking temperature and time measurements

- Visual observation of "use by" date and stock rotation

- Visual observation of cleanliness of equipment and work surface

- Visual inspection of incoming food ingredients

Simple and clear work instructions for the control and monitoring procedures should be developed for staff to refer to:

I. What is to be checked? (e.g. the cooking temperature)

II. How is it checked? (e.g. use thermometer to measure temperature)

III. When is it checked? (e.g. measure once every half hour)

IV. Who does the check? (e.g. chef assistants)

Step 4 Establish corrective actions

If monitoring procedures reveal loss of control, corrective actions must be taken immediately. Examples of corrective actions:

- Reheat the food until its core temperature reaches 75°C or above for at least 30 seconds if the cooking temperature is inadequate.

- Adjust or repair the chiller if its temperature is higher than 4oC.

- Clean the equipment again if it is dirty.

Step 5 Keep records

Maintenance of monitoring records (e.g. temperature records of the freezer) helps evaluate whether preventive measures are adequate and efficient. You can make reference to the record sheets shown in Appendices 3 to 17 and choose the ones that are suitable for you to record the monitoring results.

Step 6 Check and review

In order to ensure that your FSP works properly, you should perform a systematic check periodically (e.g. once a week). An example of an FSP checklist is provided in Appendix 18 to assist you to develop your own inspection checklist. The checklist may help you determine areas in your operation requiring attention and improvement. In addition, you should also review your FSP at least once a year because your operation or products may change.

Examples of application of Food Safety Plan

Following are examples of possible problems and their controls for each step in the food service operation:

Step: Purchase

| Hazards | Control Limits | Monitoring Procedures* | Corrective Actions | Records | |||

|---|---|---|---|---|---|---|---|

| What | How | When | Who | ||||

|

Raw materials contaminated with

|

Raw materials obtained from approved / licensed and reputable suppliers | Evidence showing that suppliers follow good manufacturing practices | Inspect suppliers' premises and check their monitoring records | Once a year and before renewing contracts with suppliers | Purchasing manager | Avoid unqualified suppliers | Record of approved and unqualified suppliers (Appendices 5 and 6) |

| Suppliers' records on customer complaints | Check records | Before renewing contracts with suppliers | Purchasing manager | Avoid unqualified suppliers | |||

| Establish products' safety and quality specifications with suppliers (including delivery temperature of perishable foods) | Requirements mentioned in product specification | Check product specification | Before purchasing | Purchasing manager | Avoid ordering substandard foods | Purchasing record form (Appendix 7) and product specification | |

* Monitoring procedures (e.g. frequency of monitoring) should be tailor-made to suit your own operation.

Step: Receiving

Raw materials or ingredients must be checked against the specifications on deliveries. Depending upon the degree of risk they present, some food or raw ingredients will need to be checked more frequently.

| Hazards | Control Limits | Monitoring Procedures | Corrective Actions | Records | |||

|---|---|---|---|---|---|---|---|

| What | How | When | Who | ||||

| Damaged packaging and contamination with foreign matter (including food poisoning bacteria) | Packaging is intact and has no visible foreign matter | Integrity of packaging and signs of contamination | Visual checking | Receiving raw materials | Receiver | Reject raw materials and inform suppliers | Records of incoming food and supplies (Appendices 8,9 and 10) |

| Delivery vehicles are clean and hygienic and are not used for the transport of chemicals | Hygienic condition of vehicles and evidence of the vehicle being used to transport chemicals | Visual checking | Receiving raw materials | Receiver | Reject raw materials and inform suppliers | ||

| Presence and growth of food poisoning bacteria during delivery | No sign of deterioration of raw materials (e.g. appearance and odour, etc.) | General conditions of raw materials | Check the appearance of raw materials (ie. colour, smell, texture, etc.) | Receiving raw materials | Receiver | Reject raw materials and inform suppliers | |

| Not exceeding the expiry date of raw materials ("use by" or "best before" date) | Expiry date of raw materials | Check the labels | Receiving raw materials | Receiver | Reject raw materials and inform suppliers | ||

| Temperature of raw materials on arrival: 4℃ or below (chilled foods) / entirely frozen (frozen foods) | Temperature of raw materials / Appearance of food | Use thermometer and check the appearance of food | Receiving raw materials | Receiver | Reject raw materials and inform suppliers | ||

| Store chilled / frozen foods at 4℃/-18℃ or below immediately after receiving (e.g. within ten minutes) | Procedures for receiving and storing food | Visual checking | Receiving raw materials | Store keeper |

|

||

Step: Dry storage

Dry storage includes the storage of some kinds of fruits and vegetables, dried foods (e.g. cereals and seasonings) and canned or bottled foods.

| Hazards | Control Limits | Monitoring Procedures | Corrective Actions | Records | |||

|---|---|---|---|---|---|---|---|

| What | How | When | Who | ||||

|

Cross-contamination |

Group and store food according to their properties and store food in appropriate containers | Storage conditions | Visual checking | Storing / taking food ingredients | Store keeper |

|

|

| Packaging is intact and has no visible foreign matter | General conditions of food | Visual checking | Storing / taking food ingredients | Store keeper |

|

||

| Keep storage area dry and clean | Hygienic condition of storage area | Visual checking | Before off-duty | Assistant manager | Clean the storage area immediately | ||

| Cleaning records | Check records | Before off-duty | Assistant manager | Remind staff to clean storage area according to the schedule | Cleaning records (Appendix 13) | ||

| Storage area is not infested with pests | Signs of pests | Visual checking | Weekly | Assistant manager | Use proper methods (e.g. rodent traps) to capture and kill pests where there are signs of pests or employ a pest control company | Pest control monitoring and inspection records (Appendices 14 and 15) | |

| Growth of food poisoning bacteria | Use first-in-first-out (FIFO) rotation (Use date codes or marks to show the time sequence of food storage) | Date codes / marks (e.g. expiry date / receiving date) | Check date codes / marks | Daily | Store keeper | Discard food if its expiry date is passed or it has no date codes / marks | Stock records |

Step: Refrigerated storage

| Hazards | Control Limits | Monitoring Procedures | Corrective Actions | Records | |||

|---|---|---|---|---|---|---|---|

| What | How | When | Who | ||||

| Cross-contamination (e.g. cooked food contaminated by raw food) | Cover/ wrap all food and store cooked and raw food separately | Storage condition | Visual checking | Storing / taking food ingredients | Store keeper |

|

|

| Keep storage area clean | Hygienic condition of storage area | Visual checking | Storing / taking food ingredients | Store keeper | Clean the storage area immediately | ||

|

Growth of food poisoning bacteria and formation of toxins |

Storage temperature at 4C or below | Temperature of the chiller | Use thermometer | Three times a day (in the morning, at noon and before off-duties) | Store keeper |

|

Temperature record sheet for chiller (Appendix 9) |

| Storage area with good air circulation | Storage conditions | Visual checking | Storing / taking food ingredients | Chef assistant | Reorganise layout | ||

| Use first-in-first-out (FIFO) rotation (Use date codes or marks to show the time sequence of food storage) | Date codes / marks (e.g. expiry date / receiving date) | Check date codes / marks | Daily | Chef assistant | Discard food if its expiry date is passed or it has no date codes / marks | Stock records | |

Step: Frozen storage

| Hazards | Control Limits | Monitoring Procedures | Corrective Actions | Records | |||

|---|---|---|---|---|---|---|---|

| What | How | When | Who | ||||

| Growth of food poisoning bacteria | Temperature of freezer at -18 C or below | Temperature of freezer | Use thermometer | Three times a day (in the morning, at noon and before off-duties) | Store keeper | Adjust temperature or repair freezer where appropriate | Temperature record sheet for freezer (Appendix 11) |

| Storage area with good air circulation | Storage condition | Visual checking | Storing / taking food ingredients | Store keeper | Reorganise layout | ||

Step: Preparation

| Hazards | Control Limits | Monitoring Procedures | Corrective Actions | Records | |||

|---|---|---|---|---|---|---|---|

| What | How | When | Who | ||||

| Cross-contamination | Use appropriate methods (e.g. color code) to distinguish the utensils and cutting boards for handling ready-to-eat foods from raw foods. | Utensils and cutting boards | Visual checking | During working | Chef assistant |

|

Corrective action record sheet (if taken) (Appendix 12) |

| Ready-to-eat fruits and vegetables are clean and hygienic | Procedures of washing fruits and vegetables | Visual checking | During working | Chef assistant | Discard contaminated ready-to-eat fruits and vegetables | ||

|

Growth of food poisoning bacteria and formation of toxin |

Frozen foods to be thawed under / in

|

Methods of thawing (e.g. thawing temperature, food is packed in waterproof package, water is cool and running while thawing) | Visual checking | During working | Chef |

|

|

| Frozen foods are adequately thawed (no hardening with ice) before cooking | Condition of the thawed foods | Touching and visual checking | Before cooking | Chef assistant | Thaw the food under suitable condition further | ||

| Maximum time for holding thawed foods and cold perishable foods at above 4℃is four hours | Length of time holding perishable foods at above 4oC in food preparation area | Visual checking | During working | Chef assistant |

|

||

Step: Cooking

| Hazards | Control Limits | Monitoring Procedures | Corrective Actions | Records | |||

|---|---|---|---|---|---|---|---|

| What | How | When | Who | ||||

| Survival of food poisoning bacteria and bacteria spores | Core food temperature reaches 75°C or above for at least 30 seconds | Core food temperature | Use thermometer | Each batch | Chef | Continue cooking food to required temperature | Temperature record sheet |

|

Condition of food during and after cooking | Visual checking | Each batch | Chef | Continue cooking food until thoroughly cooked | ||

Step: Cooling

| Hazards | Control Limits | Monitoring Procedures | Corrective Actions | Records | |||

|---|---|---|---|---|---|---|---|

| What | How | When | Who | ||||

| Cross-contamination | Food is protected from contamination during cooling | Cooling environment (whether there is any source of contamination) | Visual checking | During working | Chef assistant |

|

|

| Containers are clean and hygienic | Cleanliness of containers | Visual checking | Before use | Chef assistant | Clean and sanitise the containers | ||

| Growth of food poisoning bacteria and formation of toxin | Containers less than five cm/ two inches high | Height of containers | Visual checking | Before use | Chef assistant | Use shallow containers | |

| Cool to 4℃ or below in six hours (Cool from 60℃ to 20℃ in two hours and then to 4℃ or below in the next four hours) | Cooing time and temperature of foods | Use timer and thermometer | Every hour | Chef assistant |

|

Temperature record sheet | |

Step: Reheating

| Hazards | Control Limits | Monitoring Procedures | Corrective Actions | Records | |||

|---|---|---|---|---|---|---|---|

| What | How | When | Who | ||||

| Survival of food poisoning bacteria | Heat food to a core temperature 75°C or above for at least 30 seconds | Core food temperature | Use thermometer | Each batch | Chef | Continue reheating food to required temperature | Temperature record sheet |

Step: Hot holding

| Hazards | Control Limits | Monitoring Procedures | Corrective Actions | Records | |||

|---|---|---|---|---|---|---|---|

| What | How | When | Who | ||||

| Cross-contamination | Cover / wrap all food | Storage conditions | Visual checking | During working | Chef assistant |

|

|

| Growth of food poisoning bacteria and formation of toxin | Keep food above 60°C | Temperature of food in holding containers | Use thermometer | Every two hours | Chef assistant |

|

Temperature record sheet (Appendix 11) |

Step: Display (applicable to businesses providing buffets)

| Hazards | Control Limits | Monitoring Procedures | Corrective Actions | Records | |||

|---|---|---|---|---|---|---|---|

| What | How | When | Who | ||||

| Cross-contamination | Display ready-to-eat foods* separately from non ready-to-eat foods (e.g. uncooked meat) | Condition during display | Visual checking | During display | Attendants# | Discard contaminated food and review the display layout | |

| Use different sets of utensils to handle ready-to-eat foods* and non ready-to-eat foods | Utensils for handling food | Visual checking | During display | Attendants | Discard contaminated food and clean the contaminated utensils | ||

| Avoid topping up an displayed batch of food with a fresh one | Handling of food | Visual checking | During buffet operation hours | Chef | Retrain the staff | ||

| Displayed leftovers are not kept for further use | Handling of leftovers | Visual checking | During and after display | Chef | Discard all leftovers | ||

| Growth of food poisoning bacteria and formation of toxin | Keep food above 60°C | Temperature of food | Use thermometer | Every hour | Attendants |

|

Temperature record sheet (Appendix 11) |

| Keep cold foods (e.g. raw oysters, sashimi and salad) at 4℃ or below | Conditions during display | Visual checking | During display | Attendants | Discard food if it is held above 4℃ for more than four hours and review display procedures | Temperature record sheet for chiller (Appendix 11) | |

| Temperature of chillers | Use thermometer | Every two hours | Attendants | Adjust storage temperature or repair chiller where appropriate | |||

| Keep displaying food in small portions | Condition during display | Visual checking | During display | Manager | Review the quantity of food for display to shorten display time and retrain the relevant staff to explain the procedures of display | ||

* Sashimi and raw oysters are classified as ready-to-eat foods.

#Attendants should be present at buffet tables to monitor the hygienic condition of displayed food.

Step: Transport

| Hazards | Control Limits | Monitoring Procedures | Corrective Actions | Records | |||

|---|---|---|---|---|---|---|---|

| What | How | When | Who | ||||

| Cross-contamination | Delivery persons have good personal hygiene practices | Personal hygiene practices of staff | Visual checking | During delivery | Supervisor | Retrain delivery persons | |

| Delivery vehicles are clean and hygienic and are not used for the transport of chemicals | Hygienic condition of vehicles and evidence of the vehicles being used to transport chemicals | Visual checking | During delivery | Supervisor |

|

Vehicle inspection sheet | |

| Growth of food poisoning bacteria and formation of toxin | Keep hot foods above 60°C and cold foods at 4°C or below | Temperature of foods | Use thermometer | During delivery | Delivery person |

|

Temperature record sheet (Appendix 11) |

Chapter 4

Basic requirements for a Food Safety Plan

An FSP should also include some basic activities (e.g. cleaning and sanitation, personal hygiene, pest control, waste disposal and staff training) so that potential problems arising from the food production process will be prevented more effectively. Listed below are the examples of these activities.

A. Cleaning and sanitation

Food preparation areas, facilities, equipment and all food contact surfaces should always be kept clean because food residues and dirt may contaminate food resulting in food poisoning. A cleaning programme should therefore be developed to ensure that cleaning and sanitising be carried out in a systematic, regular and effective manner.

The steps for cleaning and sanitising of utensils are as follows:

- Remove debris by wiping, scraping

- Rinse with hot water

- Clean with detergents

- Rinse with water

- Sanitize with hot water or chemical sanitisers (instructions for use and safety precautions on the labels should always be followed when using chemical sanitisers)

- Air dry

In order to ensure that cleaning and sanitation is carried out effectively in your premises, you should develop a well-planned cleaning and sanitation programme and maintain relevant records for evaluation. A well-planned cleaning and sanitation programme should include the following elements:

- areas, utensils and equipment to be cleaned

- frequency of cleaning required for each item

- cleaning procedure specified for each item

- equipment and methods to be used

- chemicals or systems to be used

- the staff responsible for each task

An example of cleaning programme

| Item | Frequency | Equipment and chemicals | Method | Responsible person |

|---|---|---|---|---|

| STRUCTURE | ||||

| Floors | End of each day or as required | Broom, damp mop, brush, detergent and sanitiser |

|

|

|

Walls, window and ceiling |

Monthly or as required |

Wiping cloths, brush and detergent |

|

|

| FOOD CONTACT SURFACES | ||||

|

Work tables and sinks |

After use |

Wiping cloths, detergent and sanitiser |

|

|

| EQUIPMENT | ||||

| Utensils, cutting boards, knives, and other cooking equipment | After each use | Wiping cloths, brush, detergent and sanitiser |

|

|

| Refrigerator, freezers and storage areas | Weekly or as required | Wiping cloths, brush and detergent |

|

|

| HAND CONTACT SURFACES | ||||

|

Door knobs, drawers and switches |

Daily |

Wiping cloths and detergent |

|

|

B. Personal hygiene

Good personal hygiene is essential to ensure food safety. Food poisoning bacteria may be present on the skin and in the nose of healthy people. All food handlers must therefore maintain a high standard of personal hygiene and cleanliness in order to avoid transferring food poisoning micro-organisms to food. The following points need to be considered by all food handlers:

Handwashing

Hands must be washed:

- Before working

- Before preparing food

- After going to toilets

- After handling raw foods

- After licking fingers, coughing, sneezing, eating, drinking or smoking

- After touching ears, nose, hair, mouth, or other bare body parts

- After touching pimples or sores

- After handling waste

- After carrying out cleaning duties

- After changing soiled clothes

- After handling animals

- After any other unhygienic practices

1. Wet hands with warm running water

2. Apply soap

3. Rub hands for 20 seconds (If necessary, use a nail brush to clean nails. However, the brush must be kept clean and sanitary.)

4. Rinse hands thoroughly

5. Dry hands with a paper towel (the paper towel can then be used to turn off the tap)

6. Turn off the tap with the paper towel

Hand care

- Keep fingernails short and clean

- Cover all wounds or cuts on hands or arms completely with bright-coloured waterproof wound strip

- Wear disposable gloves if there are wounds on hands. Change both gloves and wound strip regularly

Clothing and appearance

- Uniforms and aprons (or clothes) should be clean at the beginning of a work shift

- Wear a hair restraint (hat or hairnet)

- Avoid wearing jewellery while handling and preparing food

- Avoid using strong perfumes/after-shaves

- Do not wear uniforms / aprons outside the food preparation area

Personal hygiene practices while handling food

· Avoid touching nose, mouth, hair and skin during food preparation

· Do not smoke in food premises

· Do not cough or sneeze directly onto food. Wash hands after coughing or sneezing

· Wash hands after blowing nose

· Use disposable tissues to wipe hands

Infection

· Food handlers should be free from any illnesses such as gastroenteritis or flu

· Cease working and report to the manager when feeling ill

C. Pest control

Pests may contaminate food and cause foodborne illness. A pest control programme should be developed to eliminate pests and prevent pests from infesting your food premises. An effective pest control programme should be able to prevent access, deny harbourage and eradicate any pests present.

Design of facilities

- Seal all gaps around fittings or in walls or floors

- Keep doors to the outside closed at all times

- Fit windows open directly into food preparation areas with screens (with apertures of two mm2or less) to keep insects out

- Cover ventilation ducts and floor drains

Preventive measures

- Store food and supplies properly:

- Cover them properly

- Store them at least 30cm/twelve inches off the floor and 15cm/six inches away from walls

- Store them at low humidity (50 per cent or less)

- Apply first-in-first-out system

- Remove cartons, newspapers, etc. that may attract and harbour pests

- Store and remove garbage properly and regularly. Keep refuse bins covered

- Keep garbage in sealed plastic bags and inside tightly covered refuse bins

- Clean up spillages of food immediately · Keep toilets clean and hygienic

Inspection

- Inspect both outside and inside of premises frequently (e.g. weekly) for signs of pests

- Check incoming food and supplies for signs of pests (e.g. any pest is harboured inside the packaging of food and supplies)

- An example of a pest control inspection record sheet is provided in Appendix 14

Elimination

- Use chemical, physical or biological means (e.g. rodent traps) where there are signs of pests

- Use a zapper or insecticutor to capture and kill flying insects. Ensure zappers are not above or within three metres of a food preparation or storage area.

- Avoid spraying insecticide over food preparation surfaces

- Hire a professional pest control company when necessary

- An example of a pest control monitoring record sheet is provided in Appendix 15

D. Waste disposal

Waste can be regarded as any item of foods, ingredients, packaging materials, etc. which is not suitable for further use and intended to be disposed of. Waste should be controlled carefully since it presents a risk of contamination of food.

- Waste disposal bins should be placed near the working area of food preparation rooms and positioned conveniently to operating staff

- Waste disposal bins should be clearly distinguishable from other storage bins

- A defined area should be allocated for the storage of waste pending disposal

- When food waste is removed from food preparation area pending disposal, it must be placed in a tightly covered waste storage bin

- Plastic liners should be used in waste disposal and storage bins

- Waste disposal and storage bins should be emptied when full or on a regular basis

- Waste disposal bins should be cleaned and sanitised daily and placed upside down and off the floor to drain overnight

E. Staff training

Training offers food handlers a better understanding of how food can become contaminated, and how foodborne illnesses can be avoided through proper food handling procedures. Each food business must decide what training their food handlers need by identifying the areas of their work most likely to affect food hygiene and safety.

Examples of basic knowledge of food safety:

- Main factors contributing to outbreaks of foodborne illnesses

- Temperature control of potential hazardous foods

- Proper ways of using equipment (e.g. the skill of using thermometer, knowledge of handling cooking and storage equipment)

Examples of basic knowledge of food hygiene:

- Skills and significance of maintaining good personal hygiene practices

- Knowledge and skills of cleaning and sanitising

- Pest control

- It is a good practice for a business to identify the training needs of each staff member

- It is also a good practice to keep training records of every staff member

- Training needs should be reviewed on a regular basis and should be assessed against the role and responsibilities, existing skills, experience and previous training of the staff

- An example of a staff training record sheet is provided in Appendix 16

F. Handling customer complaints

Customer complaints should be handled carefully because they help reflect possible problems that may be overlooked by the management during food production. Depending upon the results of investigation, appropriate amendments to the FSP should be made where necessary.

- Establish complaint handling procedures

- Document all customer complaints

- Record details including the date, customer details, reasons for complaining and action taken

- An example of a customer complaint record sheet is provided in Appendix 17

Chapter 5

Relevant websites

For more information about Food Safety Plan, please browse the following websites:

Regional food safety authorities

Food Standards Australia New Zealand

Canadian Food Inspection Agency

U.S. Food and Drug Administration

Food Safety and Inspection Service (U.S.)

International organisations

Food and Agriculture Organisation

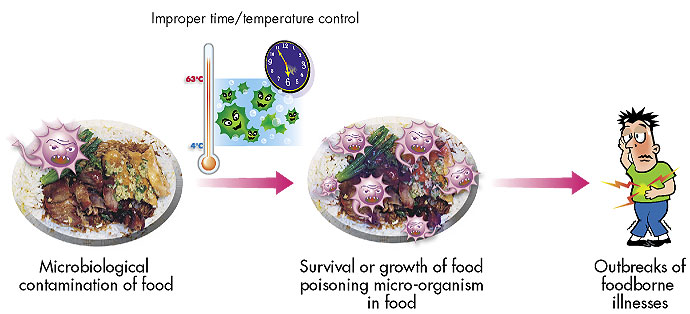

Appendix 1

Main factors contributing to outbreaks of foodborne illnesses

Below is a list of the most common factors contributing to outbreaks of foodborne illnesses. These factors can be categorized into two groups:

1. Microbiological contamination of food

i. Use of unsafe food source

ii. Cross-contamination

iii. Infected food handlers

2. Survival or growth of food poisoning micro-organisms in food (related to improper time / temperature control)

i. Inadequate cooking

ii. Prolonged storage of food between 4°C and 60°C (Temperature danger zone at Appendix 1(i))

iii. Improper cooling

iv. Inadequate reheating

v. Inadequate thawing of food before cooking

vi. Preparation of food too far in advance and storage of food at temperature danger zone vii. Improper handling of leftovers

Appendix 1(i)

Temperature danger zone

Food should be stored at 4℃ or below or above 60℃ to retard the growth of food poisoning bacteria.

* Note: Some of the food poisoning bacteria can still grow at low temperature, e.g. Listeria monocytogenes.

Appendix 2

Examples of hazards

A hazard is anything in food that may cause harm to consumers. Hazards may be biological, chemical or physical:

Biological

| Sources | Suspected Food Items | |

|---|---|---|

| Salmonella spp. | gastro-intestinal tract of humans and animals | Meat and its products, milk and eggs, etc |

| Staphylococcus aureus | skin, hair, nose and throat of humans, and animals | Flour confection, milk and its products, egg products, ham and ready-to-eat foods (e.g. cooked food, sandwiches and sushi), etc |

| Vibrio parahaemolyticus | marine environment and seafood | Shellfish to be eaten raw and undercooked shellfish, etc |

| Listeria monocytogenes | soil, faeces of humans and animals, sewage and grease | Raw milk, soft cheese, poultry, meat and cold dishes (e.g. salad, coleslaw and sandwiches), etc |

| Norwalk-like virus | Sewage and shellfish | Salad, raw vegetables and shellfish (e.g. oysters), etc |

| Hepatitis A virus | Sewage and shellfish | Shellfish (e.g. clams and oysters), etc |

Chemical

| Suspected Food Items | |

|---|---|

| Prohibited pesticides | Leafy vegetables |

| Toxins (Fish) | Coral reef fish |

| Mycotoxins | Corn, nuts / peanuts and their products, cereal and figs |

Physical

| Glass fragments |

| Metal fragments |

| Stones |

Appendix 3

Food Safety Plan Worksheet

| Production Flow Chart |

Appendix 4

Food Safety Plan Worksheet

Step

| Hazards | Control Limits | Monitoring Procedures | Corrective Actions | Records | |||

|---|---|---|---|---|---|---|---|

| What | How | When | Who | ||||

|

|

|||||||

Appendix 5

Approved Suppliers Record Form

| Product | Details of supplier (e.g. name, address, phone number and food safety management system, etc) | Date approved | Remarks | Signature | Date |

|---|---|---|---|---|---|

Appendix 6

Unqualified Suppliers Record Form

| Product | Details of supplier (e.g. name, address, phone number and food safety management system, etc) | Causes of failure | Signature | Date |

|---|---|---|---|---|

Appendix 7

Purchasing Record Form

| Ordered date | Name of product | Supplier | Amount of product | Packaging |

Specification |

Arrival date | Signature |

|---|---|---|---|---|---|---|---|

Appendix 8

Record Form for Receiving Frozen Products

| Date | Time | Name of product | Supplier | Amount of product | Packaging |

Temp |

Comments | Corrective actions (if any) | Signature |

|---|---|---|---|---|---|---|---|---|---|

Appendix 9

Record Form for Receiving Chilled Products

| Date | Time | Name of product | Supplier | Amount of product | Packaging | Temp(oC) | Comments | Corrective actions (if any) | Signature |

|---|---|---|---|---|---|---|---|---|---|

Appendix 10

Record Form for Receiving Dry Products

| Date | Time | Name of product | Supplier | Amount of product | Packaging | Comments |

Corrective actions |

Signature |

|---|---|---|---|---|---|---|---|---|

Appendix 11

Temperature Log

|

|

| Date | Time | Temperature | Comments |

Corrective actions |

Signature | |||

|---|---|---|---|---|---|---|---|---|

|

|

|

|

||||||

| Audited by : | Date: |

* Please delete where inappropriate.

Appendix 12

Corrective Action Record Form

| Date | Time | Control limit contravened | Corrective action | Signature |

|---|---|---|---|---|

Appendix 13

Cleaning Schedule Record Form

|

Equipment to be cleaned |

Location of the equipment |

||

|---|---|---|---|

|

Cleaning agents to be used |

Cleaning frequency |

||

|

Cleaning method |

|

||

| Date | Time | Signature | Remark |

|---|---|---|---|

| Audited by:: |

Date: |

Appendix 14

Pest Control Inspection Record Form

| Date | Location checked | Sign of pests (Yes / No) | Action taken | Signature |

Appendix 15

Pest Control Monitoring Record Form

| Date | Location checked | Type of baits | Evidence of infestation | Action taken | Signature |

|---|---|---|---|---|---|

Appendix 16

Staff Training Record Form

| Name | |

|---|---|

| Position |

| Previous training received | ||||

|---|---|---|---|---|

| Name of programme/ Type of certificate | Contents | Organisation | Date of training | |

|

Additional training required:

|

||||

Appendix 17

Customer Complaint Record Form

|

Date of complaint |

|

|---|---|

|

Name of the complainant |

|

|

Telephone number of the complainant |

|

|

Cause of the complaint |

|

|

Ways of sending the complaint |

Oral / Written |

|

Staff receiving the complaint |

|

|

Staff handling the complaint |

|

|

Result of the investigation |

|

|

Corrective action taken |

|

|

Response of the complainant |

Not satisfactory/Satisfactory |

|

Remarks |

Appendix 18

Food Safety Plan Manager

Self-inspection Checklist

Part 1

| Checked by: | Date: |

I Personal Hygiene

|

Standard |

Yes | No | N/A | Comments | Date corrected |

|---|---|---|---|---|---|

| Employees wear proper clothing | |||||

| Food handlers wear hair restraints | |||||

| Fingernails are short, unpolished and clean | |||||

| Jewellery is limited to watch and plain ring | |||||

| Gloves are changed at critical points | |||||

| Open sores, cuts or bandages on hands are completely covered while handling food | |||||

| Adequate handwashing and drying facilities are available | |||||

| Wash hands routinely and thoroughly, follow proper handwashing procedures | |||||

| No smoking in preparation, service, storage, and warewashing areas | |||||

| Eat, drink or chew gum only in designated areas away from work areas | |||||

| Employees take appropriate action when coughing or sneezing | |||||

| Disposable tissues are used and disposed of when coughing/blowing nose | |||||

| Personnel with infections restricted | |||||

| Employee illnesses are documented |

II.Utensils and Equipment

| Standard | Yes | No | N/A |

Comments

|

Date corrected |

|---|---|---|---|---|---|

| All small equipment and utensils, including cutting boards and can openers, are thoroughly cleaned between uses | |||||

| Small equipment and utensils are air dried | |||||

| Work surfaces are clean to sight and touch | |||||

| Work surfaces are washed and sanitised between uses | |||||

| Thermometers are washed and sanitised between each use | |||||

| Drawers and racks are clean | |||||

| Small equipment is inverted, covered, or otherwise protected from dust or contamination when stored |

III.Cleaning and Sanitising

|

Standard |

Yes | No | N/A | Comments | Date corrected |

|---|---|---|---|---|---|

| Three-compartment sink is properly set up for warewashing (wash, rinse and sanitise) | |||||

| Cleaning procedures are in place for utensils, equipment and premises | |||||

| Chorine test kit or thermometer is used to check sanitising rinse | |||||

| If heat sanitizing is used, utensils should be immersed in boiling water | |||||

| If using chemical sanitiser, proper dilution should be ensured | |||||

| Cleaning chemicals and equipment are stored properly | |||||

| The utensils are allowed to air dry | |||||

| Adequate clean wiping cloths are provided | |||||

| Cleaned tableware and utensils are properly stored |

IV.Waste Disposal

|

Standard |

Yes | No | N/A | Comments | Date corrected |

|---|---|---|---|---|---|

| Adequate waste disposal bins are provided | |||||

| Waste disposal bins are washed and sanitised | |||||

| Waste disposal bins are emptied as necessary | |||||

| Cartons and waste are removed from food preparation area | |||||

| Waste storage area is insect- or rodent-proved | |||||

| Proper storage is available for brooms, mops, and other cleaning utensils outside food preparation area |

V. Pest Control

|

Standard |

Yes | No | N/A | Comments | Date corrected |

|---|---|---|---|---|---|

| Screens are put on open windows and doors and properly maintained | |||||

| A pest control program is in place | |||||

| No evidence of pests is present |

Part 2

| Checked by: | Date: |

Food Production

|

Stage |

Control limits |

Yes | No | N/A | Comments | Date corrected |

|---|---|---|---|---|---|---|

|

Receiving |

Inspect incoming food and supplies immediately upon receipt | |||||

| All foods and supplies are promptly moved to proper storage areas | ||||||

| Receiving area is clean and free of food debris, boxes or other refuse | ||||||

| Chilled and frozen products are arriving at correct temperature | ||||||

| Products are supplied by approved suppliers | ||||||

|

Dry Storage |

Storage area is dry and well ventilated | |||||

| All foods and paper supplies are stored off the floor | ||||||

| All foods are labelled with name and (expiry / delivery) date | ||||||

| FIFO (First-in-first-out) is used | ||||||

| There are no bulging or leaking canned goods in storage | ||||||

| Opened bulk-food supplies are stored in containers with tight-fitting lids | ||||||

| Food is protected from contamination | ||||||

| All surfaces and floors are clean | ||||||

| Chemicals and cleaning supplies are stored away from food and other food-related supplies | ||||||

|

Cold Storage |

Thermometers are conspicuous and accurate | |||||

| Proper temperatures are maintained: 4oC or below for chillers and -18oC or below for freezers | ||||||

| All foods are stored off the floor | ||||||

| Units are clean | ||||||

| Food is arranged in a way to allow air circulation | ||||||

| Cooked foods are stored above or separately from raw foods | ||||||

| Proper chilling procedures have been practised | ||||||

| All foods are properly wrapped, labelled and dated | ||||||

| FIFO (First-in-first-out) is used | ||||||

|

Food Handling |

Frozen foods are thawed under refrigeration or in cold running water | |||||

| Food is kept under appropriate temperature (i.e. cold foods at 4°C or below and hot foods above 60°C) | ||||||

| Food is tasted using proper method | ||||||

| Food is prevented from cross-contamination | ||||||

| Food is handled with clean utensils or clean hands | ||||||

| Avoid touching parts of utensils that directly contact food | ||||||

| Proper cooling procedures have been practised | ||||||

| Hot Holding | Units are clean | |||||

| Food is heated to 75°C or above for at least 30 seconds before placing in hot holding | ||||||

| Temperature of food being held is above 60°C | ||||||

| Food is protected from contamination | ||||||

| Display | Display of ready-to-eat and non ready-to-eat foods is separated | |||||

| Different sets of utensils are used to handle ready-to-eat and non ready-to-eat foods | ||||||

| Hot foods are kept above 60°C | ||||||

| Cold foods (e.g. raw oysters, sashimi and salad) are kept at 4℃or below | ||||||

| Transport | Transport containers and carts are regularly cleaned and sanitised | |||||

| Proper temperatures are maintained during transport: at 4℃ or below for cold foods and 60℃ or above for hot foods | ||||||

| Transport carts and containers for food are covered | ||||||

| Transport vehicles are clean |

This document can be downloaded from the Food Safety Plan webpage of

the Centre for Food Safety: www.cfs.gov.hk

For more information, please contact the

Communication Resource Unit, Food and Environmental Hygiene Department at

8/F, Fa Yuen Street Municipal Services Building,

123A Fa Yuen Street, Mongkok, Kowloon

or

at tel 2381 6096

8/2009