Feature Article

Review of Food Poisoning Outbreaks Related to Food Premises and Food Businesses in 2021

This article reviews the food poisoning outbreaks (FPOs) related to local food premises and food businesses reported to the Centre for Food Safety (CFS) in 2021.

FPOs Related to Local Food Premises and Food Businessesas possible.

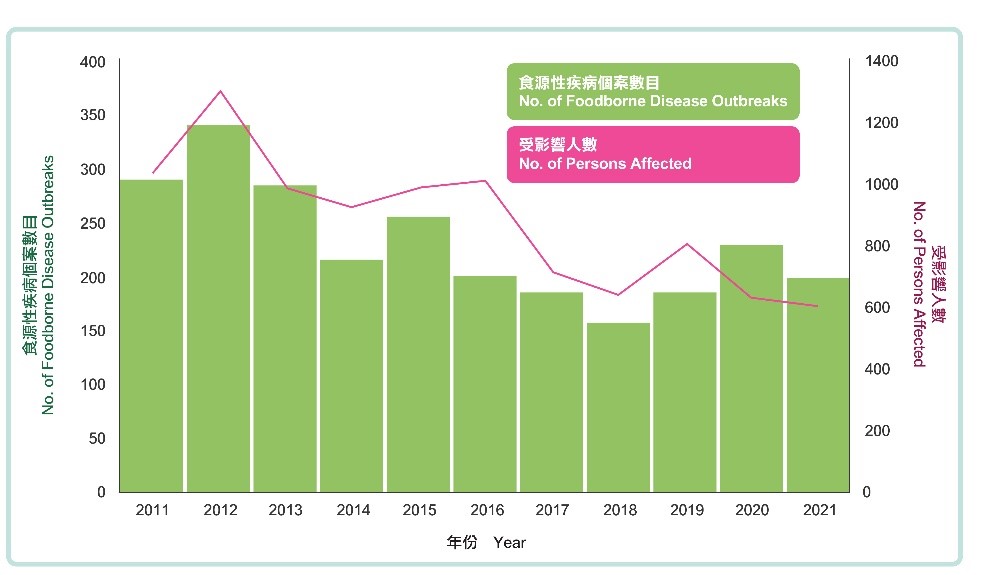

In 2021, the CFS received 199 referrals of FPOs in which 608 persons were affected (Figure 1).

Figure 1: Number of FPOs related to local food premises and food businesses and corresponding number of persons affected from 2011 to 2021

Causative Agents and Contributing Factors

In 2021, bacterial foodborne agents continued to be the main cause (67%) of FPOs, with Vibrio parahaemolyticus (54% of all bacterial cases) overtaking Salmonella (23%) as the leading agent, followed by Staphylococcus aureus (11%), Bacillus cereus (7.6%) and Clostridium perfringens (3.8%). Viral causes accounted for 27% of the FPOs in the year, the single causative agent being norovirus. The remaining FPOs (6%) were related to biochemical causes (e.g. mushroom toxins, ciguatera toxins). “Contamination by raw food”, consumption of “raw food” and “inadequate cooking” were the three most frequently identified factors contributing to all FPOs in 2021.

Highlights on Major Epi-linked FPOs in 2021

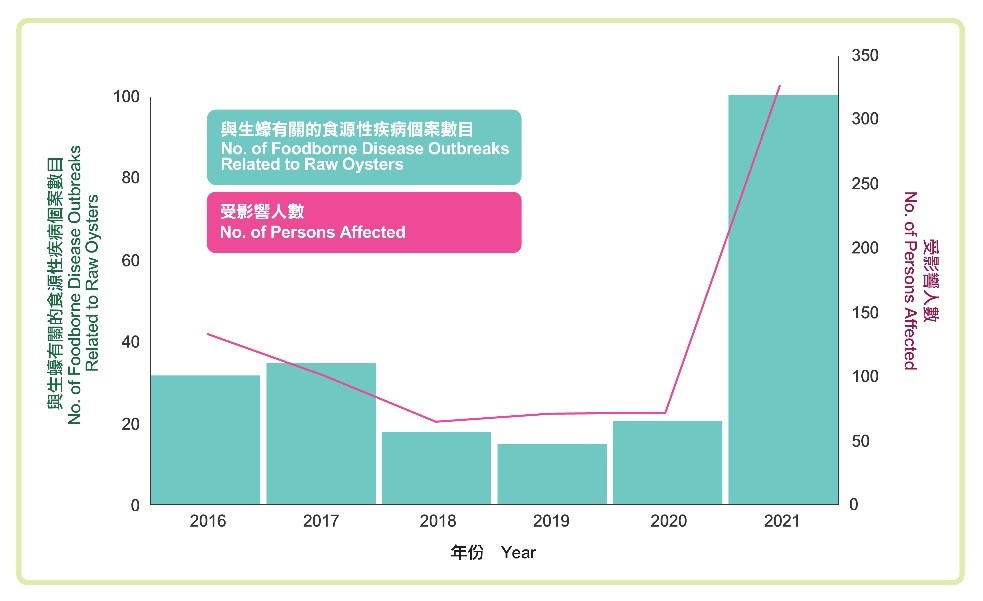

The CFS noted that there was an increase in FPOs related to raw oysters in 2021. A total of 101 cases (326 people affected) were recorded in the year, whereas it was 24 outbreaks in annual average in the five-year period from 2016 to 2020 (Figure 2). Live oysters were the incriminated food in the FPOs linked to raw oysters in 2021. Storage temperature and wet storage were the main issues identified.

Figure 2: Number of FPOs linked to raw oysters and corresponding number of persons affected from 2016 to 2021

The largest cluster of FPOs in 2021 was recorded in October. It comprised 32 epi-linked cases related to a restaurant with 99 people affected. The FPOs were confirmed to be caused by Vibrio parahaemolyticus. Raw oysters were among the incriminated food items in these outbreaks.

Importance of Storage Temperature

Field investigation of the above FPO cluster revealed that the refrigerators for storing ready-to-eat seafood at the restaurant were defective. According to the restaurant staff, the refrigerators had been malfunctioning for two to three days before the incriminated raw oysters were served for consumption by the affected persons. Not only was the refrigerator temperature above 4°C, the refrigerators were also overfilled to the extent that the cooling ability was compromised.

Pitfalls of Wet Storage

Wet storage of live oysters, including mixing and immersing oysters of different origins in the same tank, was identified in a number of FPOs associated with raw oysters in 2021. The stool sample of a patient in these cases was tested positive for norovirus. The CFS had instructed the importers/suppliers concerned to cease this practice and discard the reimmersed raw oysters.

For wet storage, live oysters are submerged under water or subjected to heavy spraying. In its Code of Practice for Fish and Fishery Products, the Codex Alimentarius (Codex) specifies that live bivalve molluscs must not be reimmersed in or sprayed with water after they have been packaged and sent off the distribution centre. In general, food authorities of oyster-exporting countries are against wet storage of live oysters subsequent to their export. In the European Union (EU), reimmersion of oysters after packaging is prohibited.

Oysters and Food Safety Risks

Oysters are filter feeders that will take in pathogenic microorganisms such as bacteria (including Vibrio parahaemolyticus) and viruses (norovirus, hepatitis A virus, etc.) from the surrounding seawater. These pathogens can grow rapidly at above 4°C. To contain the growth of these harmful microorganisms, it is important to maintain proper storage of raw oysters. Besides, we should beware of the food poisoning risks of consuming oysters without thorough cooking. Susceptible individual such as the elderly, young children, pregnant women and immunocompromised patients, are particularly affected.

Conclusion

In general, there was a downward trend in the number of FPOs associated with food premises and food businesses and the number of persons affected in the period 2012-2018. The figures remained somewhat static in the past three years. However, the numbers increased in 2021 due to lapses in food safety practices in relation to raw oysters. This illustrates that a lot of consumers can be affected by a small number of food traders negligent in hygiene practices.

To reduce risks, raw oysters should only be consumed in or obtained from reliable licensed premises. Oysters intended for consumption after cooking should not be eaten raw. The trade is also reminded to place emphasis on hygiene practices and stop wet storage of raw oysters.

Mascot ON in Lesson

Avoid Importing or Manufacturing Food Products Containing Cannabidiol

Canada passed the Cannabis Act in 2018 to legalise and regulate access to cannabis for recreational use. We would be able to buy food products and beverages containing cannabis in Canada. However, illicit import of cannabis or any products that contain controlled cannabinoids (e.g. tetrahydro-cannabinol, or THC) constitutes a criminal offence under the Dangerous Drugs Ordinance (Cap. 134) in Hong Kong.

Cannabidiol (CBD) is another cannabinoid present in cannabis plants. It is not a dangerous drug controlled under the Ordinance. Nonetheless, as it is difficult to extract pure CBD, other controlled cannabinoids (e.g. THC) are likely to be found in food products and drinks that contain CBD.

Local food traders should avoid breaching the law by exercising due care not to import or manufacture products that contain cannabis or THC. Members of the public should pay attention to the list of ingredients and the labelling on food products when bringing them from overseas into Hong Kong or ordering food online.

(Remarks: The control of cannabidiol (CBD) as a dangerous drug under the Dangerous Drugs Ordinance (DDO) (Cap. 134) has come into effect since 1 February 2023).

Safety of Genetically Modified (GM) Food

Some places like mainland China, Australia, New Zealand, Canada, the EU and the United States have implemented pre-market safety assessment schemes (PMSASs) for GM foods to tie in with their development of relevant industries and confirm the safety of newly emerging GM events.

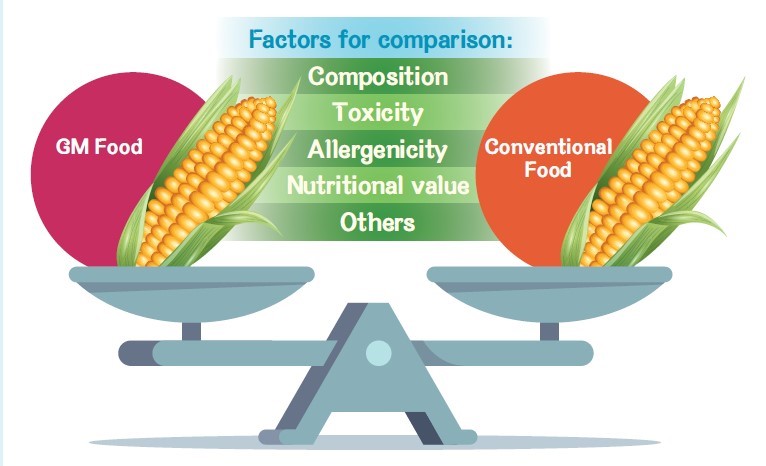

While the operational details of PMSASs in different places may vary, these schemes all adopt the scientific principles and guidelines recommended by the Codex and the Organisation for Economic Cooperation and Development. In other words, they are operated within the same framework. The safety assessment approach is based on the principle of the comparative approach, i.e. the safety of a GM food is assessed in relation to its conventional counterpart having a history of safe use, taking into account both intended and unintended effects (see Figure).

Figure: The comparative approach aims at determining whether a GM product has new or altered hazards in order to establish its safety in relation to its conventional or non-GM counterpart. The conventional counterpart, which has a long history of consumption, is generally considered safe.

Today, the World Health Organization states that GM foods currently available on the international market have passed safety assessments and are unlikely to pose risks to human health. In addition, there is no evidence that GM foods have resulted in food safety issues in the countries where they are available for sale after assessment.

In recent years, studies conducted by institutes in different places (e.g. the Institute of Genetics and Developmental Biology of the Chinese Academy of Sciences, the US National Academy of Sciences, the Royal Society of the United Kingdom, the US Society of Toxicology, the Australian Academy of Science and the American Cancer Society) also commonly point out that GM foods are as safe for consumption as their non-GM counterparts.

In Hong Kong, the Government has previously proposed to implement a mandatory PMSAS for GM foods. As most food in Hong Kong is imported, the CFS of the Food and Environmental Hygiene Department (FEHD) has been monitoring international studies on GM food safety to further develop related proposals.

The CFS notes that in recent years, study reports of different places have pointed out that GM foods are as safe for consumption as their non-GM counterparts. GM events of GM foods commercially produced and sold internationally have generally passed safety assessments in other countries and regions with a PMSAS in place for years. They are unlikely to pose health risks to humans. Therefore, another round of local pre-market safety assessment for GM foods will have little practical effect on improving the food safety level in Hong Kong and may not be an effective use of resources.

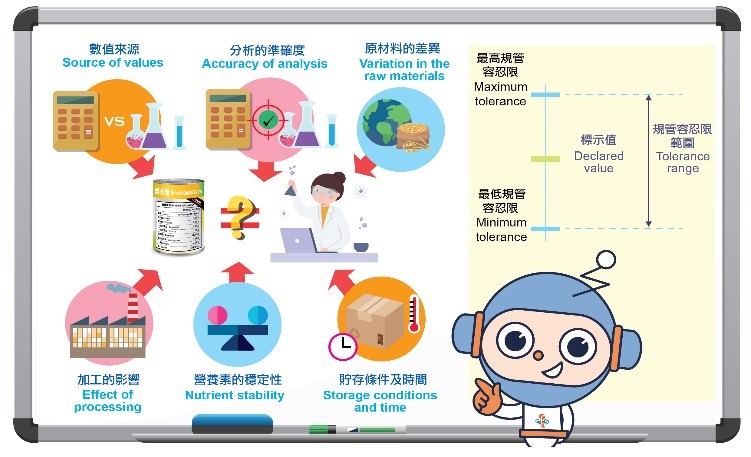

Providing Reliable Food Nutrition Labels

Food is a difficult matrix. The declared values of a nutrient may not be entirely consistent with the test values of a specific food sample obtained in a laboratory. This can be caused by several factors. Due to differences in seasons, processing procedures, sources of ingredients, nutrient stability and storage conditions (see Figure below), there may be batch-to-batch discrepancies in the nutrient values of the same food product or even discrepancies in nutrient values within the same batch. However, the nutrient contents of foods should not deviate substantially from their labelled values. Against the above background, the Government has set tolerance limits for nutrition labelling with a view to providing an important benchmark for the trade to follow.

The Codex’s Guidelines on Nutrition Labelling have laid down some major principles for setting tolerance limits for declaring nutrition information on food labels. By making reference to these principles and the practices of jurisdictions including mainland China, Singapore and the United States, Hong Kong has set tolerance limits for various kinds of nutrients, as listed out in the technical guidance notes applicable to general prepackaged foods and formulae and foods for infants and young children (IYC).

Uncertainty in measurement is unavoidable. It relates to the range of possible measured values within which the true value of a measurement falls. For example, a certain nutrient of a food is measured to be 10.0mg/100g by testing, but various factors, such as sample homogeneity, precision of instrument, testing methods and environment, will affect the accuracy of the measurement result. Measurement uncertainty refers to a plausible range. Taking the range 8.5 to 11.5mg/100g as an example, it is the range within which the true value of a nutrient lies. As measurement uncertainty is not considered in setting tolerance limits, it is usually taken into account in compliance checking.

Labelling of Negligible Amounts of Nutrients

It is an international practice to regard nutrients of insignificant amounts as negligible and declare such amounts as “zero”. However, the definition of “zero” for different nutrients varies among different jurisdictions. Using trans fat as an example, if a food product contains 0.5g or less of trans fat per serving, “0g” can be declared on the nutrition label in the United States, whereas in Hong Kong “zero” trans fat means that there is no more than 0.3g of trans fats per 100g of food.

The trade should pay extra attention in labelling certain nutrients of a food product as “zero” in amount. For example, a prepackaged food with no free sugar added can still have sugar in its primary ingredients. For the sake of compliance, the trade should refer to the technical guidance notes published by the CFS to familiarise themselves with the definitions of different nutrients applicable to food available in the local market.

Compliance Checking and Communication with the Trade

In Hong Kong, the regulations related to nutrition labelling are stipulated under the Food and Drugs (Composition and Labelling) Regulations (Cap. 132W). The CFS has implemented a surveillance system for nutrition labelling. From 2018 to 2020, the CFS conducted more than 21 000 label inspections. A total of 1 500 samples were tested. The unsatisfactory rates were 0.45% and 6.2% respectively. The 98 unsatisfactory samples involved nutrient discrepancies in energy, protein, fat, carbohydrate, sugar and sodium. The CFS has instructed the vendors concerned to take remedial actions, including suspending the sale of the affected prepackaged food products until rectification of the irregularities concerning nutrition labels is made.

Considering the possible differences in nutrient contents within the same batch of food products, the Expert Committee on Food Safety of the CFS endorsed the proposal to collect as many as 12 samples from the same batch of food products in sampling where possible. Overseas jurisdictions such as Canada have similar recommendations and opine that several samples should be collected for nutrition label inspections.

As for communication with food businesses, the CFS organises regular technical meetings and workshops to facilitate compliance with the relevant requirements by food traders. In addition, the CFS has set up a designated website as a nutritional labelling database with practical guidelines on preparation of legible labels, determination of serving sizes and making of nutrition claims for reference by the public. The website can also be used for seeking accredited laboratories in and outside Hong Kong.

In short, food traders are advised to ensure that the information provided on nutrition labels is accurate. For more details about declaring nutrition information, they can refer to the technical guidance notes on general prepackaged foods and IYC formulae and foods published by the CFS.

Figure: Factors leading to discrepancies between declared nutrient values and test values obtained in laboratories (left), and an illustration of tolerance limits (right)

Spot Check

Separation of Duties to Minimise Risks of Cross-contamination

The food trade is committed to fighting the epidemic to safeguard the health of customers. Apart from implementing social distancing measures and providing takeaway options, food traders have also stepped up efforts in enhancing personal hygiene of their staff and maintaining food safety and environmental hygiene. In collecting used utensils, restaurant staff would easily come into contact with the salvia of customers left on the utensils. Their hands are likely to be contaminated by viruses. If they do not wash their hands thoroughly before serving meals to other customers, it may result in cross-contamination. To minimise such risks, restaurants should arrange for designated staff to clear eating utensils used by customers. These staff members should not take up other duties, including serving meals. They are also advised to wear a different set of uniforms for easy identification by customers and other staff members.

In fact, restaurant staff in various positions and customers should observe hand hygiene at all times.

Safe Kitchen/Trade Talks/Food Safety Guidelines

Safe Kitchen

Introduction to “Safe Kitchen” Scheme

To facilitate trade members in adopting the Five Keys to Food Safety and good hygienic practices to enhance food safety in daily operation, the CFS has integrated the existing channels of risk communication to launch a new platform, namely “Safe Kitchen”, to communicate with the trade. The platform serves to provide food safety information of greater practical importance to meet the operational needs of catering outlets.

The “Safe Kitchen” platform disseminates up-to-date food safety information (including food safety guidelines and relevant legislative amendments) to the trade through a host of channels including WhatsApp, emails and dedicated websites. In response to food poisoning outbreaks in restaurants, the platform will also issue food alerts to remind the trade of the points to note in preventing future occurrences so that the risk of food poisoning can be minimised.

New dedicated websites and risk information exchange platforms will be rolled out under the “Safe Kitchen” Scheme. In addition, training materials tailor-made for the trade and different workshops for kitchen staff will be provided to enhance food safety and hygiene awareness among food handlers. Members of the trade are welcome to scan the following QR code to download the registration form for the “Safe Kitchen” Scheme in order to receive the latest food safety information in a timely manner.

Food Safety Talks 2022

The CFS will organise food safety talks and the Workshop on Good Hygiene Practices (GHPs) from April to November 2022 to promulgate proper food processing procedures among food handlers, with a view to enhancing food safety by promoting GHPs and the implementation of the Food Safety Plan in food processing through active participation of the food trade and full cooperation between the trade and the Government.

The talks will be conducted in Cantonese and the participants will receive a certificate of attendance. Please refer to the CFS website for details.

Food Safety Guidelines

Beware of Toxic Plants Resembling Radix Fici Simplicissimae

Many people like to have soup for a meal. Some families even make soup every day. Various ingredients can be used for making soup. Radix Fici Simplicissimae (RFS) is a popular ingredient for soup preparation in recent years.

RFS is the root of a plant belonging to the Moraceae family. Although RFS is not toxic, its plant grows in wild areas where some poisonous plants like Gelsemium elegans (a toxic plant of the Loganiaceae family) are prevalent. As RFS and the roots of these toxic plants are quite alike, they may be mixed up during harvesting. In Hong Kong, there were poisoning cases involving the consumption of RFS suspected to be contaminated with toxic plants.

Advice to the Trade

- Avoid picking wild plants for food.

- Source food from reliable suppliers.

- Do not consume plants not known to be edible. Do not use these plants if you are in doubt.

Is Wet Storage Appropriate for Imported Raw Oysters?

A popular seafood enjoyed by connoisseurs worldwide, raw oysters are also an infamous culprit of food poisoning. The shellfish, often served uncooked, continues to appear in the records of local foodborne disease outbreaks. The CFS notices that some importers would reimmerse imported raw oysters into saltwater tanks for storage before sale. Such an improper practice in handling oysters intended for direct consumption was implicated in several food poisoning cases this year. This temporary storage method is meant for extending the shelf-life of oysters, but it may pose additional food safety risks to consumers.

Oysters with Inherent Risks

Being a filter feeder, an oyster can filter litres of water hourly. As oysters would absorb suspended food particles from the seawater during feeding, disease causing microorganisms such as bacteria (e.g. Vibrio parahaemolyticus and Vibrio vulnificus) and viruses (e.g. norovirus and Hepatitis A virus) would accumulate in them. Hence, there is a risk of direct intake of these microorganisms in consuming undercooked oysters. In terms of food safety, eating raw oysters is not recommended, particularly for susceptible individuals.

However, some consumers still prefer eating raw or lightly cooked oysters. To strike a balance between market demand and customers’ safety, oyster farms often strictly follow the guidelines stipulated by different jurisdictions. For instance, the EU stipulates that only oysters raised from Class A production areas (i.e. with the least bacterial count) can be harvested for direct consumption, and sometimes additional purification procedures are put in place to minimise microbiological contamination. Despite all safety measures, occasionally imported raw oysters can still be contaminated with pathogens, leading to food poisoning and food recalls.

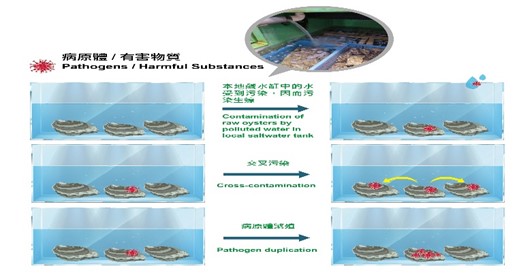

Problems with Wet Storage

Wet storage refers to the practice of storing live shellfish temporarily by submerging them in water or under heavy spraying. In its Code of Practice for Fish and Fishery Products, the Codex specifies that live bivalve molluscs must not be reimmersed in water or sprayed with water after they have been packaged and sent off the distribution centre. In fact, reimmersion can ruin the end-product quality of raw oysters. Moreover, the temperature of the saltwater tank is usually not low enough to suppress bacterial growth. Mixing of raw oysters from different batches in the same water tank can result in cross-contamination of shellstocks. Instead of prolonging the shelf-life of oysters intended for direct consumption, food traders should store raw oysters in a controlled and uninterrupted cold chain for the shortest possible time to ensure food safety.

Figure: Contamination risks of raw oysters during wet storage

Fulfilling Requirements to Secure Food Safety

Wet storage of imported raw oysters is not in line with international requirements. Food authorities of oyster exporting countries like France, Ireland and Australia are against wet storage of oysters after export. In the EU, reimmersion of oysters following packaging is prohibited. In Hong Kong, it is a licensing condition of the restricted food permit issued by the FEHD that oysters to be eaten in raw state shall be kept at a temperature between 0°C and 4°C. Hence, keeping oysters at higher temperatures will constitute a breach of the condition and may affect the validity of the permit/licence. Furthermore, wet storage could tamper with the quality of raw oysters such that the oysters may not be compatible with the food standards endorsed by the health certificate and recognised by the authorities of exporting countries as fit for human consumption. To protect public health and the quality of raw oysters, food traders are advised to observe the above requirements.

Key Points to Note

-

Consumption of raw oysters carries inherent risks.

-

Wet storage allows microorganisms to spread and replicate in the saltwater tank. The quality of oysters and food safety will be compromised. The water for wet storage can also be a source of contamination.

-

Authorities of oyster exporting countries may not recognise raw oysters undergoing wet storage as fit for human consumption.

Advice to the Trade

-

Do not reimmerse raw oysters in water. It can ruin the quality and safety of oysters.

-

Purchase raw oysters with corresponding health certificates from reliable sources. Upon delivery of stocks, verify them and make sure that they are all attached with a shellfish tag which allows tracking of the products from harvest to sale.

-

In receiving a shipment of raw oysters, make sure that the oysters meet the temperature requirement (i.e. below 4°C) and immediately place them in a cooler in the temperature range of 0°C to 4°C for temporary storage.

News on CFS

- Trade Talk on Reducing Acrylamide, Glycidyl Fatty Acid Esters (GE) and 3-monochloropropane-1,2-diol (3-MCPDE) in Food

On 25 October 2021, the CFS organised the Trade Talk on Reducing Acrylamide, Gglycidyl Fatty Acid Esters (GE) and 3-monochloropropane-1,2-diol (3-MCPDE) in Food to facilitate the trade in minimising acrylamide in food (especially potatoes, cereal-based products and stir-fried vegetables). The CFS’s previous risk assessment studies on the above substances were presented. The recommended levels and standards related to these substances set by international and local food regulatory bodies and the relevant trade guidelines were also introduced.

Please browse the following webpages for the content of the talk:

https://www.cfs.gov.hk/english/whatsnew/whatsnew_act/whatsnew_act_2021_Trade_Talk.html

https://www.cfs.gov.hk/english/food_leg/files/Acrylamide_E_New_3.pdf

https://www.cfs.gov.hk/tc_chi/food_leg/files/Acrylamide_C_New_3.pdf -

Food Safety Seminar for Trade 2021

The CFS held a food safety seminar for the trade on 22 December 2021. It was conducted by Dr Christine WANG, Controller, CFS, Dr Henry NG, Principal Medical Officer (Risk Assessment and Communication) and Dr Samuel YEUNG, Consultant (Community Medicine) (Risk Assessment and Communication). Members of the expert team (including Dr Jason ON, Fisheries Officer (Veterinary Public Health), Ms Janny MA, Scientific Officer (Standard Setting), Dr Violette LIN, Scientific Officer (Nutrition Labelling), Ms Melva CHEN, Scientific Officer (Programme Planning), Mr HO Kwok-wai, Scientific Officer (Salt Reduction) and Mr NG Wai-keung, Superintendent (Food Surveillance)) were present to share the latest food safety information with the participants.

The topics discussed included “Storage of Imported Raw Oysters, “Harmful Substances in Food (Amendment) Regulation 2021”, “Handling of Burgers in Local Restaurants ― From a Food Safety Perspective”, “Food Labelling and Nutrition Labelling of Prepackaged Food” and “Updated ‘Salt / Sugar’ Label Scheme for Prepackaged Food Products”. The seminar enabled the Government and the trade to exchange information and views on current and important food safety issues in Hong Kong for collaborative action to protect food safety.

Please visit the following webpage for detailed information about the seminar:

https://www.cfs.gov.hk/english/whatsnew/whatsnew_act/Food_Safety_Seminar_for_Trade_2021.html -

Trade Talk and Press Briefing on“Food Safety of Burgers”

Burgers are very popular in Hong Kong. In recent years, some local restaurants even provide burgers prepared with rare or medium rare meat patties. Their taste and mouthfeel are much distinct from well-done burgers.

To promote awareness of food safety of burgers among the trade, the CFS organised a trade talk on “Food Safety of Burgers” on 24 February 2022 to illustrate the proper ways of handling burgers under the Hazard Analysis and Critical Control Point system. It is hoped that by enhancing food traders’ understanding of food safety and healthy eating, everyone can enjoy food in a safe and healthy way.

The CFS has also complied the Guideline on Safe Preparation of Burgers at Food Premises to facilitate catering premises to take appropriate measures in food preparation in ensuring that the beef burgers produced and sold are safe for consumption.

The CFS has also complied the Guideline on Safe Preparation of Burgers at Food Premises to facilitate catering premises to take appropriate measures in food preparation in ensuring that the beef burgers produced and sold are safe for consumption.

Ask Our Mascots

Cooked or Undercooked

#Steak: I want to be a good steak.

#Mascot ON: Fine. Find a food thermometer and see if it would rate you as “well-done”.

Is the above scene familiar to you? How can we tell if a piece of meat is fully cooked? Yes, we can use a food thermometer to check if the core temperature of the meat is over 75°C. This is the way to obtain an accurate reading.

There are different types of food thermometers (https://bit.ly/3ETGNrf). In using a food thermometer to check the internal temperature of a food item, bear in mind the following:

✅ Place the tip of the probe into the centre of the food (or the thickest part of a piece of meat);

✅ Do not let the thermometer touch any bony parts of the food or any side of the food container;

✅ Clean the thermometer thoroughly each time after use.

If you know the correct ways to use a food thermometer, you should not be worried about mixing up raw or undercooked food with cooked food.

Knowledge Improvement Quiz

- To prevent foodborne diseases, we should:

- consume raw seafood.

- ensure that the food in a hot pot or a barbecue meal is thoroughly cooked before consumption.

- use the same set of chopsticks and utensils to handle raw and cooked food.

- In using a food thermometer to check the internal temperature of a food, we should bear in mind the following:

- Let the thermometer touch the bony parts of the food.

- Insert the probe into the centre of the food (or the thickest part of a piece of meat).

- Place the thermometer on the food surface.

- Which of the following is the correct way to thaw frozen foods?

- Leave the food to be thawed on the kitchen worktop for thawing at room temperature in advance (e.g. one day ahead).

- Immerse the food to be thawed in still water.

- Place the food to be thawed in the fridge (0°C to 4°C) in advance (e.g. one day ahead).

Answers:

1. B 2. B 3. C

Diary of Mascot ON

Captain GUS Teaches You How to Defrost Food Safely

ON: People tend to cook more at home during the COVID-19 pandemic. Do you know the importance of complete thawing of food and the correct defrosting methods? For this question, I have invited Captain GUS, who is experienced in thawing food, to explain the proper defrosting methods to ease your worries.

Captain GUS: Food cannot be thoroughly cooked unless it is fully thawed. If food is thawed at room temperature, the bacteria present in the food before freezing may grow again. To ensure food safety, two defrosting methods are recommended.

-

For fast defrosting of frozen meat, place the meat under cold running water or put it in the microwave oven and select the “defrost” setting. Rapid Defrosting

Rapid Defrosting

ATTENTION

ATTENTION

Food cannot be refrozen after rapid defrosting. The defrosted food should be cooked and consumed immediately

-

Defrosting in the Fridge

Defrosting in the Fridge

Place the food to be thawed in the fridge (0℃ to 4℃) in advance (e.g. one day ahead).

ATTENTION

ATTENTION

To prevent cross-contamination due to dripping of juices from raw meat or seafood onto other foods, store the food to be thawed in a sealed container and place it under cooked or ready-to-eat foods.