Risk Assessment Studies

Report No. 7

MICROBIOLOGICAL RISK ASSESSMENT OF ICE-CREAM

SEPTEMBER 2001

Food and Environmental Hygiene Department

HKSAR

Correspondence:

Risk Assessment Section

Food and Environmental Hygiene Department

43/F, Queensway Government Offices,

66 Queensway,

Email: enquiries@fehd.gov.hk

Table of Contents:

- Abstract

- Introduction

- Objective

- Production of Ice-cream

- Potential Microbiological Hazards

- Regulatory Framework

- Microbiological Quality of Ice-cream

- Discussion

- Conclusion & Recommendations

- Reference

- Figure 1: Flow Chart of Ice-cream Production

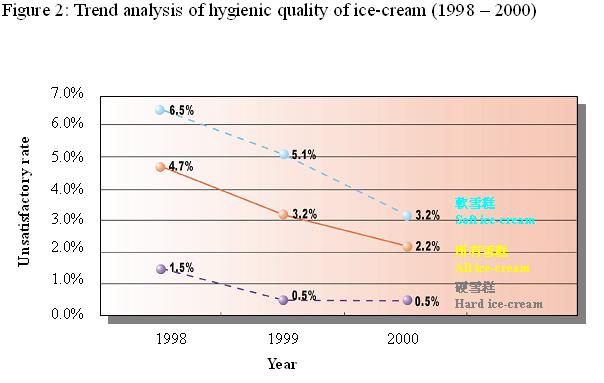

- Figure 2: Trend Analysis of Hygienic Quality of Ice-cream

- (1998 – 2000)

- Table 1: Hazards and Typical Control in the Production of Ice-cream

- Table 2: Microbiological Surveillance Results of Ice-cream

- (1998 – 2000)

Risk Assessment Studies

Report No. 7

MICROBIOLOGICAL RISK ASSESSMENT OF ICE-CREAM

An Evaluation of Microbiological Surveillance of Ice-cream

1998 – 2000

Abstract

Ice-cream is a frozen dairy product. It is sold in soft or hard status. The production of ice-cream includes totally eight steps. Pasteurization, freezing and hardening are the main steps to eliminate the microbiological hazards. In

INTRODUCTION

Ice-cream represents a congealed dairy product produced by freezing a pasteurized mixture of milk, cream, milk solids other than fat, sugars, emulsifier and stabilizers. Products of dairy origin are the main ingredients of ice-cream. These include whole milk, skimmed milk, cream, frozen cream, condensed milk products and milk solid. Other ingredients include flavouring matters and water. Fruits, nuts, candies and syrups are optionally added into ice-cream for flavour enrichment. Two types of ice-cream, soft and hard, are available on the market.

OBJECTIVE

2. This paper describes the manufacturing procedures, identifies the potential microbiological hazards and outlines the local regulatory framework of ice-cream products. The food surveillance findings in the period of 1998-2000 are reviewed and analyzed to evaluate the actual microbiological hazards in ice-cream.

PRODUCTION OF ICE-CREAM

3. The production of ice-cream includes many steps classified under the following three main parts (Figure 1) –

- Ice-cream mix making (mixing of ingredients, pasteurization and homogenization);

- Soft ice-cream production (aging and freezing); and

- Hard ice-cream production (packaging, hardening and storage).

4. The manufacturing of ice-cream mix involves mixing of ingredients, pasteurization and homogenization. For soft ice-cream, pre-made ice-cream mix is supplied to the retail outlets under refrigeration (< 7°C). Aging and freezing at around -5°C are performed in the vending machines at the retail level. Other ingredients, such as fruits and nuts, may be added to the soft ice-cream at the time of sale for flavour enrichment. In frozen confection factories, the soft ice-cream will be packed and hardened to produce the hard ice-cream. The following paragraphs describe the technological details of each processing step.

Mixing of ingredients

5. The first step of preparing ice-cream mix is to combine the liquid ingredients and heat them to around 43°C. Then, sugar and other dry ingredients, except nuts and fruits, are added to the lukewarm mix.

Pasteurization

6. The mixture is then pasteurized by a heating process, either in batch or continuous modes, depending on the production size. Pasteurization temperatures for ice-cream mix, around 70°C for 10 – 30 minutes (1), are higher than that for plain milk because high fat and sugar contents tend to protect bacteria from heat treatment.

Homogenization

7. The pasteurized mix is then homogenized. High pressures of 4.1 x 106 Pa (600 psi) to 1.7 x 107 Pa (2500 psi) are used to break down fat globules(2). This pressure can clump fat globules and, together with the added emulsifiers, can prevent churning of fat into butter granules (milk fat) during freezing step. Homogenization also improves the texture of ice-cream. In other words, the ice-cream becomes smoother. After that, the homogenized mix is cooled down to 4°C for further processing. For production of soft ice-cream using vending machines, it is packed and delivered to the retail outlets.

Aging

8. Aging is the first step in soft ice-cream production. The mix is held in sterilized vats from 3-24 hours at temperature of around 4°C or lower. It allows some physical changes, such as fat crystallization, adsorption of protein onto fat globules, and incensement of the mix's viscosity. These changes lead to quicker whipping to the desired overrun [1] in freezing process, smoother ice-cream body and texture, and slower ice-cream melt-down.

Freezing

9. During freezing, air is incorporated in the mix and cooled down to around -5°C. Freezing must be performed as quickly as possible to prevent the formation of large ice crystals. The air cells in ice-cream should be small and evenly distributed in order to maintain a stable frozen foam. At this low temperature, -5°C, not all water particles are crystallized and, therefore, ice-cream is only in semisolid state. The semisolid ice-cream emerging from the freezer is similar to the constituency of soft ice-cream produced at the retail level. Other ingredients, like fruits, nuts, or syrup, may then be added to enrich the flavour of ice-cream.

Packaging

10. To produce hard ice-cream, the semisolid ice-cream is packed into cartons or drums for hardening process to form specific shape of ice-cream products and to have longer shelf-life (more than one year).

Hardening

11. The pre-packed semisolid ice-cream is then placed in a hardening room where the temperature of about -34°C is maintained. This low temperature keeps the core temperature of ice-cream at around -18°C. Hardening should be performed quickly to prevent the formation of large ice crystal and to maintain better quality of ice-cream.

Storage

12. After hardening, the hard ice-cream will then be placed back in the cold store rooms with temperature of around -18°C. From this stage, the hard ice-cream must be kept at -18°C or below throughout storage, transportation and display.

POTENTIAL MICROBIOLOGICAL HAZARDS

13. Ice-cream, a milk-based product, is a good media for microbial growth due to high nutrient value, almost neutral pH value (pH ~6-7) and long storage duration of ice-cream (3). However, pasteurization, freezing and hardening steps in the production can eliminate most of the microbiological hazards. According to the Frozen Confections Regulation under Chapter 132, ice-cream must be heat-treated during the production process. Pasteurization is most commonly applied heat treatment in the dairy industry. This can destroy almost all pathogenic bacteria in milk. The subsequent process that subjects the mixtures to freezing temperature can also inhibit the growth of any remaining flora. Hardening is also the important control point that further reduces the hazards (4). Furthermore, as automatic machines are commonly used for ice-cream making in dairy industry, the chance of contamination through direct hand manipulation can be reduced.

14. Nevertheless, there are some steps in the production of ice-cream that (Figure 1) can lead to the microbiological hazards. Table 1 summarizes the possible hazards associated with different stages of ice-cream production (5). Heat treatment by pasteurization can destroy most of the specific pathogens that pose risk to public health. However, the potential microbiological hazards found in the final products can still be introduced after pasteurization through adding contaminated ingredients and improper handling procedures (6). This is especially important in the preparation of soft ice-cream as its final stage of the production is carried out at point of sale. Some pathogens that can survive in food even at low temperature include Salmonella spp., Listeria monocytogenes, Campylobacter spp. and Yersinia spp. (7).

15. For ice-cream products, L. monocytogenes is of significant food safety concern worldwide (3). In Hong Kong, regular surveillance to monitor L. monocytogenes in ice-cream has been in place. In 1997, L. monocytogenes was found in 4 imported ice-cream samples. Consequently, the importer had voluntarily recalled all incriminated ice-cream products on sale. No report of any persons being affected was received in that case.

REGULATORY FRAMEWORK

Local manufacture and sale

16. The composition of ice-cream is defined in Part II of Schedule 1 of the Food and Drugs (Composition and Labelling) Regulations (Chapter 132, sub. leg. W). Ice-cream shall contain not less than 5% fat, 10% sugar and 7.5% milk solids other than fat: Provided that ice-cream containing any fruit, fruit pulp or fruit puree shall either conform to the aforesaid standard or, alternatively, the total content of fat, sugar and milk solids other than fat shall not be less than 25% of the ice-cream including the fruit, fruit pulp or fruit puree, as the case may be, and such total content of fat, sugar and milk solids other than fat shall include not less than 7.5% fat, 10% sugar and 2% milk solids other than fat. For the purpose of the aforesaid standard relating to ice-cream, "sugar" means sucrose, sugar or solids of any sweetening material derived from starch, provided that no ice-cream shall contain less than 7.5% sucrose.

17. For control of ice-cream, premises manufacturing ice-cream must be covered by valid Frozen Confection Factory licence under the Frozen Confection Regulation. Frozen Confection permits are also required for retail outlets selling ice-cream in bulk or cone in original wrappers. All these premises are also required to comply and observe relevant licencing requirements and conditions.

18. The Frozen Confection Regulation stipulates the requirement for the manufacturing of frozen confections including ice-cream and the microbiological standards of the finished products. In addition, the microbiological limits for Listeria monocytogenes in the guidelines of ready-to-eat food are used for the monitoring.

19. For imported ice-cream, the Frozen Confections Regulation requires that all frozen confections imported to HKSAR from a source of manufacture must be approved by the Food and Environmental Hygiene Department (FEHD). As of June 2001, a total of 29 brands of imported ice-cream products have been approved for sale in the local market.

MICROBIOLOGICAL QUALITY OF ICE-CREAM

20. In Hong Kong, ice-cream samples are regularly taken at points of entry, local manufacturing plants, and retail outlets for food safety control. According to the Frozen Confections Regulation, any frozen confection for sale should not contain more than 50 000 bacteria per gram or more than 100 coliform organisms per gram.

Hygiene quality

21. In 1998 – 2000, a total of 16,379 ice-cream samples were taken and examined for TBC and coliform organisms. 61% (10,018 samples) were soft ice-cream products and 39% (6,361 samples) were hard ice-cream products. Of the period under study, 543 out of 16,379 ice-cream samples (3.3%) failed the stipulated hygienic quality. The corresponding figures for soft and hard ice-cream were 4.9% (492) and 0.8% (51) respectively. It is obvious that majority of the failed samples were soft ice-cream.

22. Trend analysis revealed similar findings (Figure 2). The overall unsatisfactory rates in 1998, 1999 and 2000 were 4.7% (241/5176), 3.2% (182/5633) and 2.2% (120/5570) respectively. For soft ice-cream, the unsatisfactory rates in the same period were 6.5% (212/3268), 5.1% (171/3326) and 3.2% (109/3424) respectively. For hard ice-cream, the unsatisfactory rates in 1998, 1999 and 2000 were 1.5% (29/1908), 0.5% (11/2307) and 0.5% (11/2146) respectively.

Presence of specific pathogens

23. From 1998 through 2000, 198 additional ice-cream samples, including 94 soft ice-cream samples and 104 hard ice-cream samples, were taken for L. monocytogenes examination (Table 2). None of them was found unsatisfactory. In other words, L. monocytogenes was not isolated in any 25g of those ice-cream samples.

DISCUSSION

24. TBC and coliform organisms are commonly used to reflect hygienic status of final products and effectiveness of hygienic practice in production. Reviewing the food surveillance results, a decreasing trend of unsatisfactory rates of ice-cream was observed (4.7% in 1998; 3.2% in 1999 and 2.2% in 2000). It reflected that the hygienic quality of ice-cream sold on local market and the hygienic practice in the processing plants had been improving gradually.

25. Although the hygienic quality of both types of ice-cream were improved in the past three years, the relatively high unsatisfactory rates of soft ice-cream were observed. One main reason is that the preparation of ice-cream involves handling at both factory and retail level. At retail shops, improper storage temperature and prolonged storage time affect the hygienic quality of ice-cream mix. The problem may be aggravated by contamination from vending machines which had not been properly cleansed and disinfected (8).

26. L. monocytogenes has not been isolated in either soft ice-cream or hard ice-cream samples from 1998 to 2000. It reflected that good environmental hygiene in production of ice-cream was maintained.

CONCLUSION & RECOMMENDATIONS

27. The above study showed that the overall risk associated with the consumption of ice-cream is low. In the manufacturing processes, pasteurization is effective in destroying most of pathogenic bacteria and freezing and hardening processes can inhibit the microbial growth. Automatic machines that are widely used for ice-cream production in dairy industry minimizes direct hand manipulation and possibility of cross contamination. Furthermore, low temperature (< 7°C) of ice-cream mix is unfavorable to the multiplication of bacteria.

28. The overall unsatisfactory rates of soft ice-cream was higher than that of hard ice-cream. Good manufacturing practice (GMP) would be a good way to improve hygienic quality of soft ice-cream, especially in all steps after pasteurization. For the consumers, they should also observe some key points to avoid the exposure to microbiological hazards. The following are some recommendations.

Advice to trade

29. Key steps in production must be observed by the trade. These include –

- Obtain ingredients, such as milk, cream and ice-cream mix, from licensed and reputable sources;

- Store ingredients at proper temperature (frozen items: -18°C or below; chilled items: 0-4°C);

- Maintain the ice-cream mix (< 7°C) and ice-cream products (< -18°C) at adequate temperatures from manufacturing factory to retail outlets;

- Discard the defrosted products and do not re-freeze any melted ice-cream for sale;

- Drain off and discard the leftover of soft ice-cream daily;

- Maintain all equipment and utensils in clean and good condition; and

- Observe hygienic practices during all preparation and handling processes.

Advice to public

30. Consumers are advised to pay attention on the following –

- Buy ice-cream from reputable shops;

- Do not buy and consume any hard ice-cream which is out of expiry date or not in a good quality;

- Store ice-cream products in freezer after purchasing;

- Observe the hygienic conditions of the retail shops including common area, equipment, utensils and food handling;

- Consume soft ice-cream immediately; and

- Do not eat too much ice-cream and take a balanced diet.

REFERENCE

- Potter, N.N. & Hotchkiss, J.H. Food Science. Fifth edition. Published by: Chapman & Hall. New York. 1995.

- Walstra P. et al. Dairy Technology: Principle of Milk Properties and Processes. Marcel Dekker. New York. 1999.

- Bell, C. & Kyriakides. Listeria : Apractical approach to the organism and its control in foods. Blackie Academic & Porfessional. London. 1998.

- Andreasen, TG & Nielsen, H. Ice cream and aerated desserts. In: The technology of dairy products. 2nd Edition. Edited by Early, R. Blackie Academic & Professional. London. 1998.

- ICMSF. Micro-organisms in Foods 6 – Microbial Ecology of Food Commodities. Blackie Academic & Professional London. 1998

- Marshall, RT. Ice Cream and Frozen Yoghurt. In: Applied Dairy Microbiology. Edited by Marth, EH & Steele, JL. Marcel Dekker. New York. 1998.

- ICMSF. Micro-organisms in Foods 5 – Characteristics of Microbial Pathogens. Blackie Academic & Professional. London. 1996.

- Kambamanoli-Dimou, A. Ice Cream. In: Encyclopedia of Food Microbiology. Vol.2. Edited by Robinson, RK, Batt, CA & Patel, PD. Academic Press. 2000.

Risk Assessment Section

FPHB/FEHD

September 2001

Figure 1: Flow chart of ice-cream production

Table 1: Hazards and typical control in the production of ice-cream

| Process | Hazard | Control measure |

|---|---|---|

| Raw materials | Presence of pathogens |

|

| Pasteurization | Survival of pathogens |

|

| Aging | Recontamination Growth of micro-organisms |

|

| Filling in packaging step | Recontamination |

|

| Addition of ready-to-eat ingredients (e.g.: fruits, nuts, or syrup) |

Recontamination |

|

| Hardening | Recontamination |

|

| Storage & Transportation | Growth of micro-organisms |

|

Source: ICMSF. Micro-organisms in Foods 6 – Microbial Ecology of Food Commodities. P. 563.

Table 2: Microbiological surveillance results of ice-cream (1998 – 2000)

| Type of ice-cream | 1998 | 1999 | 2000 | Total | ||||

|---|---|---|---|---|---|---|---|---|

| No. of sample | No. of unsat. sample (unsat. rate) | No. of sample | No. of unsat. sample (unsat. rate) | No. of sample | No. of unsat. sample (unsat. rate) | No. of sample | No. of unsat. sample (unsat. rate) | |

| TBC & coliform | ||||||||

| Soft | 3,268 | 212 (6.5%) | 3,326 | 171 (5.1%) | 3,424 | 109 (3.2%) | 10,018 | 492 (4.9%) |

| Pre-packed | 1,908 | 29 (1.5%) | 2,307 | 11 (0.5%) | 2,146 | 11 (0.5%) | 6,361 | 51 (0.8%) |

| Total | 5,176 | 241 (4.7%) | 5,633 | 182 (3.2%) | 5,570 | 120 (2.2%) | 16,379 | 543 (3.3%) |

| L. monocytogenes | ||||||||

| Soft | 40 | 0 (0%) | 41 | 0 (0%) | 13 | 0 (0%) | 94 | 0 (0%) |

| Pre-packed | 27 | 0 (0%) | 39 | 0 (0%) | 38 | 0 (0%) | 104 | 0 (0%) |

| Total | 67 | 0 (0%) | 80 | 0 (0%) | 51 | 0 (0%) | 198 | 0 (0%) |

[1] Overrun is a term to describe the increase in volume caused by whipping air into ice-cream mix during freezing process. The usual range of overrun in soft ice-cream is 40% and in hard ice-cream is 70-100%. If ice-cream has 100% overrun, it has a volume of air equal to the volume of mix. In other words, 1 liter of mix makes 2 liters of frozen ice-cream of 100% overrun.