Feature Article

Food Safety Seminar for Trade 2017 - An Experience Sharing on Reducing the Use of Aluminium-containing Food Additives in Bakery Products and Reducing the Use of Salt in Food

The latest biennial Food Safety Seminar for Trade was successfully held at the Lecture Theatre of the Hong Kong Central Library on 7 July 2017 with the participation of over 200 members from the food industry. The event, organised by the Centre for Food Safety (“CFS”) of the Food and Environmental Hygiene Department, served as a platform for the Government and the trade to exchange information and views on food safety issues and combine efforts in ensuring food safety. During the seminar, trade members were advised on the legislative controls on food in Hong Kong. The Hazard Analysis and Critical Control Point (“HACCP”) System was also promoted. Besides, the trade was briefed on the updated “Guidelines on the Use of Aluminium-containing Food Additives” and the results of local studies on the reduction of salt and sugar in food were shared.

Mr Peter JOHNSTON, Quality and Food Safety Director (Greater China) of PARKnSHOP (HK) Limited, was invited as the guest speaker to share with the audience his corporation’s experience in reducing aluminium-containing food additives in bakery products and salt in food manufacturing. PARKnSHOP supermarkets, as the signatories of the Food Safety Charter 2016-2018, pledge to enhance food safety, to promote good image of the food trade and to provide safe and healthier food in accordance with the CFS guidelines. Mr JOHNSTON is also an individual associate member of the Hong Kong Retail Management Association.

Reducing the Use of Aluminium-containing Food Additives in Bakery Products

Aluminium-containing food additives serve different purposes in food processing. For example, baking powder is used as a raising agent for bakery products. Aluminium-containing food additives are the main source of aluminium in the human diet. The risk assessment study reports on aluminium in food released by the CFS in 2009 and 2016 identified relatively high concentrations of aluminium in certain food products available in the market, such as steamed bread/bun/cake, some bakery products and jellyfish (ready-to-eat form). According to the studies, the general population was unlikely to experience major undesirable health effects of aluminium. Nevertheless, for consumers who have brand loyalty to products with a high level of aluminium, their exposure to aluminium will increase and the adverse health effects of aluminium cannot be ruled out. To reduce aluminium in food, the CFS drew up the “Guidelines on the Use of Aluminium-containing Food Additives” in 2009 to set out the principles for applying aluminium-containing food additives in food production and provide recommendations to the trade for reducing the aluminium contents in their food products. The Guidelines were subsequently revised in 2016.

With reference to the above studies, Mr. JOHNSTON’s corporation checked the food items produced by its supermarkets. It was found that aluminium-containing food additives were applied in the manufacturing of coconut tarts and muffins, typically as baking power (raising agent) for the filling of coconut tarts and as ingredients for the muffin mix furnished by the supplier. To minimise the use of aluminium additives, the corporation requested the baking powder provider to deliver a new baking powder that was aluminium-free and would not affect the quality and flavour of its coconut tarts. As a result, the following formula was proposed:

Disodium dihydrogen pyrophosphate (E450)(i): 45%; sodium bicarbonate: 32%; calcium carbonate: 13%; corn starch (drying agent): 10%

The provider informed that this was an improved formula widely used by baked food manufacturers in many countries. Since the original tarts were popular among consumers, the corporation was concerned that a sudden change of recipe would affect the product’s flavour and sales. Therefore, a production test was conducted by modifying the formula of the baking powder. Subject to satisfactory evaluation of taste and quality, the new tart was offered for trial sale at designated stores. It was well received and gradually became available at all stores. Coconut tarts free of aluminium additives had been marketed for more than two years. Their sales continued to grow rather than dropped.

Likewise, the corporation asked the muffin mix supplier to switch to an aluminium-free raising agent. After testing, it was confirmed that the modified raising agent would not affect the quality and flavour of the muffins. The original product with aluminium-containing food additives was progressively replaced by the new muffin with aluminium-free mix. These products were well received in the market.

Mr. JOHNSTON said that aluminium-free baking powder had long been in existence, only that the corporation had not requested its baking powder supplier to modify the formula before. As the improved formula contained disodium dihydrogen pyrophosphate, phosphorus compounds might leave some taste in the food. However, the sweetness of coconut tarts/muffins could mask the unpleasant taste. There would be no apparent effect on the flavour of the products. Finally, Mr JOHNSTON suggested that food producers consider employing different aluminium-free additives having regard to the characteristics of their products in order to provide consumers with healthier food choices.

Reducing the Use of Salt in Food

The World Health Organization recommends that the daily sodium intake of an average adult should be less than 2,000 mg so as to reduce the risk of coronary heart disease and stroke. In this connection, the CFS conducts studies on the sodium content in local food items from time to time. It was revealed that the sodium level per 100g of the same food item varied substantially among different restaurants. Against this background, Mr JOHNSTON suggested reducing sodium (salt) in the food products available in the cooked food sections of PARKnSHOP supermarkets on a trial basis. In general, the staff was worried that the taste of food would be affected and consumers would be less willing to buy the food items. Subsequently, the corporation selected some fried rice/noodle dishes and savoury dishes for testing. The ultimate aim was to lower the sodium content of food by 40%. Totally ten adjudicators tried ten odd food items, the sodium levels of which were reduced ranging from 6% to 60%. Surprisingly, they could not tell any marked difference in taste. The difference was only noticeable in some food items with ingredients milder or bitter in taste. Mr JOHNSTON said the result proved that there was obviously room for sodium reduction in certain food items.

Despite the above, Mr JOHNSTON remarked that cooks mainly relied on their personal taste and experience to prepare food. They were generally less sensitive to the salty taste and tended to use more salt in seasoning. It would be difficult to change their habit. As such, it was necessary to establish a simple and practical mechanism to control the sodium content in food, such as centralised distribution of ingredients and strengthening of staff training, so as to achieve salt reduction. However, taking note of the business setting of an average restaurant, he believed this would not be easy to accomplish. In his view, staff education/training was very important. There was a substantial need for the staff to understand the health impact of an excessive salt (sodium) intake. He added that his corporation would continue to study effective means to reduce salt in food.

For further information about Food Safety Seminar for Trade 2017, please visit http://www.cfs.gov.hk/english/whatsnew/whatsnew_act/Food_Safety_Seminar_for_Trade_2017.html.

Readers' Corner

Food Additives in Meats

Meat is a source of protein, vitamins and minerals. It is used to prepare different meat dishes and processed meat products. To enhance food safety and quality, food additives are safely used in meat processing by the trade. For example, in order to extend the shelf life of meats and reduce wastage, preservatives are added as antimicrobials to retard the growth of microorganisms, while antioxidants are used to act against meat deterioration due to oxidation. Besides, other additives may be applied in food manufacturing to improve sensory quality, such as the addition of flavour enhancer to intensify meat flavour, or stabiliser to improve the texture of meat products.

Food Additives that May be Added to Processed Meats

Hot summer months are a high-risk period of bacterial food poisoning since bacteria grow more rapidly in warm environments. The CFS would like to remind the public to stay vigilant particularly during summer times to ensure food safety.

|

Phosphates can retard microbial growth and reduce rancidity in meats. Moreover, they can increase the water-holding capacity of meats and stabilise the texture of meat products (e.g. sausages) by creating a strong muscle protein structure so that the products will not crumble into pieces after heat treatment. |

|

Sodium nitrite can give processed meats (e.g. luncheon meat) a red colour and a curing flavour after heating. It can also retard the oxidative process and most importantly, inhibit the growth of Clostridium botulinum. |

General Principles for Using Food Additives

The use of food additives is acceptable only when it can achieve an advantage or serves a distinct or some particular technological functions. The quantity of additives for use in food should be limited to the lowest possible level necessary to accomplish their desired technical effects. In addition, their application should not present an appreciable health risk to consumers at the intended level of use or mislead consumers. For example, sulphur dioxide, a common preservative in many foods, is prohibited in fresh meats as it can delay the oxidative process to keep the fresh meat colour (purplish-red or cherry-red) from changing to brownish red, thus giving consumers the false impression that the meats are still fresh.

Regulation of Food Additives in Hong Kong

All foods available for sale in Hong Kong must be fit for human consumption. The Preservatives in Food Regulation (Cap. 132BD) specifies the types of permitted preservatives and antioxidants and their respective maximum permitted levels in specified foods including meats.

Advice to the Trade

- Ensure that the food items are in compliance with the relevant statutory requirements.

- Food additives should be used within the bounds of Good Manufacturing Practice. The quantity added should be limited to the lowest possible level necessary to accomplish the desired technological effect(s).

- Be sure to provide accurate food information on food labels, including the specific additives in use, for reference by consumers.

Red Swamp Crayfish and Rhabdomyolysis

Last year, two suspected cases of rhabdomyolysis after consumption of red swamp crayfish were reported by the Centre for Health Protection of the Department of Health. Rhabdomyolysis is characterised by disintegration of skeletal muscle fibres, which can result in kidney damage and other complications. The cause of rhabdomyolysis remains unclear. The disease is suspected to be associated with a heat-stable toxin that accumulates in the implicated food. There are actually more common causes of rhabdomyolysis, such as crush injury, overexertion, alcohol abuse, congenital metabolic myopathies, heat or cold injury, drugs and toxins. To ensure food safety, the CFS advises consumers of the following:

Advice to the Trade

- Purchase live red swamp crayfish from aquaculture farms that are regulated by the relevant authorities and from reputable exporters. Purchase red swamp crayfish products (e.g. cooked frozen crayfish tail meat) from processing plants that have adopted the HACCP (or equivalent food safety management systems) to monitor the production process.

- In Hong Kong, all food available for sale in the market must be fit for human consumption. The trade should ensure that the food they sell or import is fit for human consumption and comply with the relevant legal standards.

Red swamp crayfish (Procambarus clarkii)

(The common commercial size is 7.5 to 10.5 cm)

News on New Dishes

Mixed Veggie Curry with Rice

Japanese cuisine has been well received by people in Hong Kong. Apart from the commonly seen sashimi and sushi, Japanese curry has also grown in popularity in recent years. Unlike the Hong Kong-style curry with its strong flavour, Japanese curry tastes lighter and fresher. In this issue, Chef KWOK with over thirty years of cooking experience, who is now working at “Camper’s”, a Food Safety Charter signatory, is invited to demonstrate the preparation of a Japanese curry dish for us. The dish, “Mixed Veggie Curry with Rice”, has an assortment of 15 vegetables and is both tasty and healthy.

| Preparation Steps | Small Tips, Big Wisdom | |

|---|---|---|

|

Receiving

|

Purchase the ingredients such as curry cube, vegetables, Japanese pearl rice and spices from approved and reliable suppliers. | Upon receipt of the ingredients, check carefully to ensure their freshness. Vegetables should be refrigerated at 4ºC or below for later use. Place the other ingredients in the cabinet in an orderly manner. Foods should be consumed within their shelf life. Stick to the “first-in-first-out” principle and use the oldest stocks with the shortest shelf life first. |

|

Rinsing

|

Rinse the vegetables before use. | Rinsing vegetables thoroughly under clean running water can effectively reduce the risk of pesticide intake. Scrub produces with hard surfaces with a clean brush to remove dirt and substances including pesticides and contaminants from the surface and crevices. |

|

Cutting and Pureeing

|

Slice or cut the vegetables with some pureed for the sauce. Keep the ingredients refrigerated at 4ºC or below for later use. | Cutting the ingredients into the required shapes can shorten the time of subsequent high-temperature cooking, thus preventing the formation of harmful substances. |

|

Preparing the Sauce

|

Melt the curry cube. Add in the vegetable puree, spices and a little sea salt to prepare the curry sauce. | Estimate the amount of sauce needed in advance to avoid over-production. Keep the cooked curry sauce hot in boiling water for later use. Its internal temperature should reach 60ºC or above in order to prevent food-borne diseases. |

|

Cooking

|

Finely dice the pumpkin, sweet potato and corn after rinsing them with clean water. Put the diced vegetables and the washed rice into an electric rice cooker for cooking the vegetable rice. | Keep the vegetable rice hot (internal temperature at 60ºC or above) in the electric rice cooker to prevent foodborne diseases. |

|

Deep-frying and Stir-frying

|

Deep-fry the cut eggplant and lotus root for about 30 seconds. Then put in the cut onion, green, red and yellow bell peppers and pumpkin and deep-fry them for another 30 seconds. Stir-fry the cut broccoli, cauliflower, celery, carrot, zucchini and French beans for about two minutes. Add in the deep-fried eggplant, lotus root, onion, green, red and yellow bell peppers and pumpkin, stir-fry them for around two minutes until done. |

Lightly deep-fry the eggplant, lotus root, onion, green, red and yellow bell peppers and pumpkin. They should not be deep-fried to dark brown. The time of high-temperature cooking must not be too long in order to avoid the formation of harmful substances. |

|

Serving

|

Dish up the cooked vegetables and pour the curry sauce onto them. Serve with the vegetable rice. |

Keep the sauce hot (internal temperature at 60ºC or above) before pouring it onto the vegetables. Consume the food immediately after dishing-up. If the food is not eaten within the same day after heating, it should be cooled as quickly as possible and properly refrigerated to prevent the multiplication of Bacillus cereus. |

Tips from Chef KWOK:

- It is advisable to put vegetables into the boiling oil in order, with the ones requiring the longest cooking time first so that each ingredient is adequately deep-fried without getting overdone. For vegetables that cook slowly, deep-fry them lightly until half-cooked, then stir-fry them with the other vegetables until done. This can avoid leaving the ingredients in the boiling oil for too long a time and prevent the formation of harmful substances.

- Estimate the amount of sauce needed in advance to avoid over-production. This can help minimise pathogenic hazards.

- When dishing up, the rice should be separated from the vegetables topped with the curry sauce so that it will not absorb too much sauce at one time. Customers may dip the rice with the sauce according to personal preferences. In this way, the principle of healthy diet with less salt and sugar can be achieved.

- Blanch the vegetables if a lighter plate is preferred.

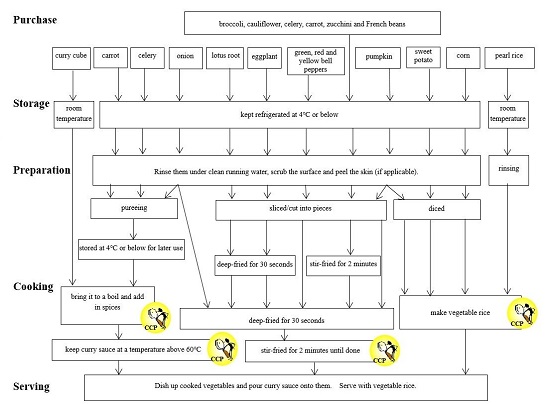

Food Safety Plan Corner

Mixed Veggie Curry with Rice

Ingredients:

Pumpkin, sweet potato, corn, eggplant, lotus root, broccoli, cauliflower, celery, carrot, zucchini, French beans, onion, green, red and yellow bell peppers, Japanese pearl rice, curry cube and spices

Steps:

- Take out the vegetables that are refrigerated at 4ºC or below.

- Rinse the vegetables thoroughly under clean running water, and use a clean brush to scrub the produces with hard surfaces.

- Slice or cut the vegetables, and puree an appropriate amount of carrot, celery and onion for the sauce. Keep the ingredients refrigerated at 4ºC or below for later use.

- Melt the curry cube. Add in the vegetable puree, spices and a little sea salt to prepare the curry sauce.

- Finely dice the pumpkin, sweet potato and corn after rinsing them with clean water. Put the diced vegetables and the washed rice into an electric rice cooker for cooking the vegetable rice.

- Deep-fry the cut eggplant and lotus root for about 30 seconds. Then put in the cut onion, green, red and yellow bell peppers and pumpkin and deep-fry them for another 30 seconds.

- Stir-fry the cut broccoli, cauliflower, celery, carrot, zucchini and French beans for about two minutes. Add in the deep-fried eggplant, lotus root, onion, green, red and yellow bell peppers and pumpkin, then stir-fry them for around two minutes until done.

- Dish up the cooked vegetables and pour the curry sauce onto them. Serve with the vegetable rice.

Production Process

Briefing of Activities

Using WhatsApp to Broadcast Food Safety Message to Consumer Liaison Group Members

As social media become increasingly popular, rumours of food safety also spread on various platforms.

To address this problem, the Consumer Liaison Group (“CLG”) has launched a programme to distribute food safety information to members via the WhatsApp broadcasting function so that they can share accurate information on food safety with friends and family members. Participants will receive the information from the CLG through WhatsApp. To protect privacy, members will not see the data (including phone numbers) of other recipients on the broadcasting list.

If you are interested in joining the CLG and the programme, please visit http://bit.ly/2x9Hxdx or email us at clg@fehd.gov.hk.

Upcoming Activities

Centre for Food Safety Trade Talk and Workshop on HACCP 2018

The CFS is organising the Trade Talk and Workshop on HACCP from March to December 2018 with the main aim of promoting proper food handling practices among employees of the food business. Through the collaboration between the Government and the trade and the active participation of stakeholders, food practitioners are encouraged to adopt the HACCP System and develop a “Food Safety Plan” in food processing to enhance food safety.

Food Safety Q&A

Why Are Bacteria Present in Cooked Meat?

It is common knowledge that raw meat should be cooked thoroughly before consumption. Thorough cooking can generally destroy most bacteria in raw meat, including the pathogenic ones. Nevertheless, food poisoning may still occur if there are subsequent lapses in food safety practices after cooking the meat.

To start with, raw meat may be contaminated with spores of certain pathogenic bacteria, such as Clostridium perfringens (“C. perfringens”) that are not readily destroyed at normal cooking temperatures. The heat of cooking will rather activate the spores to germinate and develop into vegetative cells, which can multiply rapidly in food left at room temperature for a long time. Consuming food that contains high levels of C. perfringens vegetative cells may lead to foodborne illnesses. Since food poisoning induced by C. perfringens is usually associated with inadequately cooked food or cooked food that is stored under sub-optimal temperature or cooled for an extended period of time, foods prepared in bulk (especially cooked meat and poultry dishes) and those stored at ambient temperatures with a long cooling period after cooking are at high risk.

In addition, pathogenic bacteria may be introduced into ready-to-eat cooked meat through cross-contamination. They will multiply in large quantities as a result of time and temperature abuse of the food, causing foodborne illnesses in consumers.

To ensure food safety, raw meat should be cooked thoroughly prior to consumption. The public should patronise reliable shops and always maintain good personal and food hygiene. Ready-to-eat cooked meat should be discarded if it has been held at room temperature for more than four hours. If cooked meat is kept at room temperature for less than two hours, it can be refrigerated for final use later or used before the 4-hour limit expires. Finally, food should be reheated thoroughly with the core temperature reaching 75ºC or above.

Truth against Fallacy

Fake Rice or Not?

Moon (wife) Charlie (husband)

Moon: (Exclaiming) Oh no! Put down your bowl of rice, Charlie! It’s fake rice!

Charlie: What's wrong?

Moon: Look! The grains become longer and do not crack when I roll them. This must be fake rice! Earlier the media reported that fake rice was available in the market. It’s true, isn’t it?

Charlie: Don't panic, dear. Rice contains 90% starch, and rice starch consists of amylose and amylopectin. The cooking and eating quality of rice is greatly affected by the ratio between amylose and amylopectin and their fine structures. Long-grain rice has a higher amylose content. It gives a firm and fluffy texture with grains separate when cooked. Short-grain rice, on the other hand, has a low amylose content and is soft and sticky with grains clinging together after cooking. However, this relationship is becoming blurred due to continuous improvement of rice quality from producers.

Moon: But the grains can be rolled without cracking. Why?

Charlie: First of all, most rice grains can be rolled and elongated when cooked, as rice grains have a certain degree of flexibility and elasticity. For example, glutinous rice has the highest elasticity. Grains that crack more readily upon rolling are probably those which have been refrigerated or kept overnight after cooking. It is because when cooked rice is cooled for a period of time, the starch inside the grain will undergo a process called “retrogradation” during which amylose and linear parts of amylopectin molecules will rearrange themselves to form a firmer and less flexible structure that makes the grain brittle.

Moon: Ah.

Charlie: The CFS takes rice samples at the import, wholesale and retail levels for testing under its routine Food Surveillance Programme. So, don’t believe hearsays easily.

Moon: Oh, I see.

Charlie: Now dear, please get me another bowl of rice.

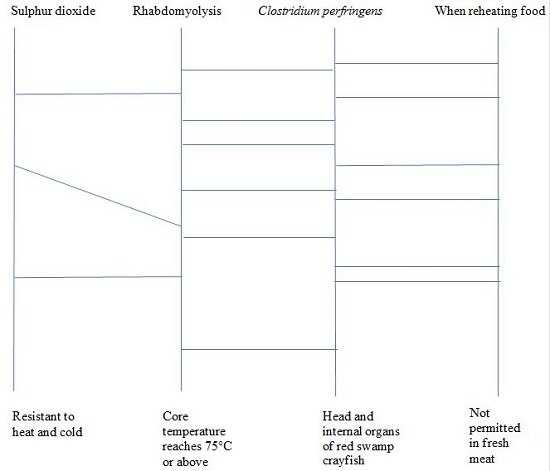

Brain Gym

Matching (Ghost Leg)

Answers:

1. Sulphur dioxide

Answer: Not permitted in fresh meat

2. Rhabdomyolysis

Answer: Head and internal organs of red swamp crayfish

3. Clostridium perfringens

Answer: Resistant to heat and cold

4. When reheating food

Answer: Core temperature reaches 75°C or above

Enquiries and Subscription

Printed copies of the Food Safety Bulletin can be obtained from the Communication Resource Unit at 8/F, Fa Yuen Street Municipal Services Building, 123A Fa Yuen Street, Mong Kok, Kowloon. For enquiries, please call 2381 6096. The public may also visit the CFS website ( www.cfs.gov.hk ) for the online version.

Enquiry hotline 2868 0000

E-mail address enquiries@fehd.gov.hk

CFS website www.cfs.gov.hk.