2010 2nd Issue

Feature Articles

(I) Benefits of Nutrition Labels

The enactment of the Food and Drugs (Composition and Labelling) (Amendment: Requirements for Nutrition Labelling and Nutrition Claim) Regulation 2008 (the Amendment Regulation) signifies a new era of food labelling in Hong Kong. After the Amendment Regulation comes into force on 1 July 2010, most of the prepackaged food products sold in Hong Kong carry nutrition labels.

The introduction of the Nutrition Labelling Scheme aims to assist the public to make informed food choices, to encourage food manufacturers to apply sound nutrition principles in the formulation of food, and to regulate misleading or deceptive labels and claims. The information on nutrition labels is very useful. It enables consumers to compare the nutrient contents of different foods to make healthier food choices. For instance, they may choose foods lower in fat, sodium (or salt) and sugar. The nutrition information also let consumers know the nutrient contents of food so that they can estimate the contribution of energy and nutrients to the overall diet and choose the right food to suit their own dietary needs.Further details on the Nutrition Labelling Scheme can be found at the website www.nutritionlabel.gov.hk.

(II) Microbiological hazards in Chinese cold dishes

Newspapers reported that the Food and Environmental Hygiene Department was investigating a suspected food poisoning case involving several people who had fallen sick after consuming cold dishes such as jellyfish and pig knuckle.

|

Andrew (manager)

|

:

|

In such a hot weather, many customers like to eat cold dishes such as pig knuckle, five-spice beef, jellyfish, Lo Shui bean curd and bean curd with lime preserved eggs. How do these kinds of food cause food poisoning? |

|

|

|||

| Samuel (chef) |

: | Improper preparation and storage of cold dishes may pose a risk of food poisoning. | |

|

Andrew

|

:

|

Why?

|

|

|

Samuel

|

:

|

The inherent properties and preparation process of some Chinese cold dishes, such as Lo Shui and like products, jellyfish and bean curd with lime preserved eggs have potential microbiological hazards. The most common types of mi croorganisms that cause food poisoning are Escherichia coli, Salmonella species, Staphylococcus aureus and Bacillus cereus.

|

|

|

|||

|

Andrew

|

:

|

How do these microorganisms contaminate the food?

|

|

|

Samuel

|

:

|

Chinese cold dishes are normally prepared or cooked in advance and stored at room temperature for a period of time before serving and they are not usually reheated before consumption. Insufficient cooking, post-cooking contamination and prolonged storage at room temperature may also pose a risk of microbiological contamination.

|

|

|

Andrew

|

:

|

Oh, I see.

|

|

|

|||

|

Samuel

|

:

|

Foods will be directly or indirectly contaminated with microorganisms if food handlers fail to follow good personal and food hygiene practices in food preparation (e.g. not washing their hands thoroughly or storing cold dishes improperly). Taking jellyfish as an example, rinsing and soaking jellyfish with contaminated water, or improper storage of cooked jellyfish may cause microorganisms to grow in large number, affecting the microbiological quality of the food products. As for bean curd with lime preserved eggs, the preparation of this cold dish involves manual handling. Cutting the lime preserved eggs with a knife used to cut raw ingredients will lead to microbiological contamination. |

|

|

Andrew

|

:

|

Now I realise there are potential microbiological hazards in Chinese cold dishes. We must handle this kind of food very carefully.

|

|

Advice to Trade

To ensure food safety, the trade is advised to pay special attention to the following key points in preparing Chinese cold dishes:

.jpg)

- Estimate the demand of each dish carefully to avoid over-production.

- Cook food thoroughly (except for food eaten raw like marinated cold cucumber) with core temperature at 75°C or above for at least 30 seconds.

- Use separate utensils to handle raw food and cooked food or ready-to-eat food.

- Keep cold dishes in the refrigerator at 4℃ or below.

In addition, the trade is also advised to take note of the following food safety measures:

.jpg)

- Purchase food ingredients from reliable sources.

- Plan the production schedule ahead to avoid preparing food too far in advance.

- Ideally, use two separate refrigerators for storing raw food and cooked food or ready-to-eat food. If raw and cooked foods or other ready-to-eat food have to be stored in the same refrigerator,

- food should be stored in containers with lids to avoid contact between raw food and cooked food or ready-to-eat food; and

- raw meat, poultry and seafood should be stored below cooked food or ready-to-eat food to prevent juices from dripping onto the cooked food or ready-to-eat food.

- Food handlers should observe good personal hygiene:

- wear clean and light-coloured outer clothing or protective overalls. If clothes become soiled during food preparation, change or clean them as necessary;

- wash hands thoroughly with soap under running water for 20 seconds before and after handling food and after going to the toilet;

- cover open wound with bright-coloured waterproof adhesive plasters or gloves; and

- stop any food handling work when there are signs or symptoms suggesting of an infectious disease such as diarrhoea, vomiting, fever, sore throat and abdominal pain.

(III) Trade Webzone – CFS website

In order to make it easier for the trade to search for information, the CFS has launched the dedicated webpage of Trade Webzone where different types of information related to the trade are provided, including the latest news on food safety, legislation and guidelines on food safety, etc. In Regulatory Control of Food, relevant guidelines are listed under different food regulations for the trade's reference to enable them to better understand the regulations.

In order to make it easier for the trade to search for information, the CFS has launched the dedicated webpage of Trade Webzone where different types of information related to the trade are provided, including the latest news on food safety, legislation and guidelines on food safety, etc. In Regulatory Control of Food, relevant guidelines are listed under different food regulations for the trade's reference to enable them to better understand the regulations.

From the Event Dates for Trade, members of the trade can browse important events including the activities which the CFS organises for them and choose to take part in any activities they find relevant. The rolling bar of the Trade Webzone also gives out the latest trade related information.

The contents of Food Alert This Week, Latest News and Recommendations will be updated regularly to provide the latest information and publications. To have a look at this information-rich webpage, please visit the following website:

http://www.cfs.gov.hk/english/trade_zone/trade_zone.html

Readers' Corner

(I) New Code of Practice for the Reduction of Acrylamide in Foods endorsed by the Codex Alimentarius Commission (Codex) in 2009 at the 32nd session

.jpg)

Acrylamide is an industrial chemical that has been used to make polyacrylamide materials for a variety of uses. Acrylamide was first identified in carbohydrate-rich foods processed at high temperature by the National Food Administration in Sweden in 2002. This was proved by subsequent studies conducted by various countries. According to the studies, acrylamide may be carcinogenic in humans, so its presence in foods has aroused public concern. Over the years, large-scale studies have been conducted in the international community to investigate the major food source for human intake of acrylamide and to explore measures to reduce the risk. Following years of discussion and efforts, the Codex endorsed the CoP for the Reduction of Acrylamide in Foods in 2009.

The available evidence shows that acrylamide is mainly formed as a result of the Maillard reaction between asparagine (an amino acid) and reducing sugar (especially glucose and fructose) in foods (such as potatoes and cereals) at high temperature, normally over 120°C, with low moisture contents. Acrylamide is generated in foods during frying, roasting and baking of carbohydrate-rich foods such as French fries, potato chips, coffee, biscuits, pastries and bread.

The Codex formulated the CoP for the Reduction of Acrylamide in Foods to provide guidance on reducing the formation of acrylamide in potatoes and cereals for national and local authorities, manufacturers and other organisations. The measures cover strategies mainly on three areas in the production process: (1) raw materials; (2) addition of other ingredients; and (3) food processing and heating.

The Codex formulated the CoP for the Reduction of Acrylamide in Foods to provide guidance on reducing the formation of acrylamide in potatoes and cereals for national and local authorities, manufacturers and other organisations. The measures cover strategies mainly on three areas in the production process: (1) raw materials; (2) addition of other ingredients; and (3) food processing and heating.

(1) Raw materials:

Raw materials with low reducing sugar and low asparagine contents may be used. As for agriculture, in the cultivation of cereals, sulphur deficient soil and excessive nitrogen fertilisation should be avoided because they will increase the asparagine contents in cereals. Food manufacturers may choose raw materials with low reducing sugar contents, e.g. in the manufacture of potato products, potato cultivars with low reducing sugar contents may be chosen, but immature potatoes as well as those stored at low temperatures should be avoided.

(2) Addition of other ingredients:

The ingredients added to foods may also contain reducing sugar and asparagine. For potato-based snacks produced from doughs, food manufacturers may use raw materials with lower reducing sugar or asparagine contents (e.g. rice flour) to partially replace the potato. For cereal based products, rice flour may be used to partially replace wheat flour so as to reduce asparagine contents in the flour. Besides, asparaginase can also reduce asparagine contents in raw materials.

The ingredients added to foods may also contain reducing sugar and asparagine. For potato-based snacks produced from doughs, food manufacturers may use raw materials with lower reducing sugar or asparagine contents (e.g. rice flour) to partially replace the potato. For cereal based products, rice flour may be used to partially replace wheat flour so as to reduce asparagine contents in the flour. Besides, asparaginase can also reduce asparagine contents in raw materials.

During the heating stage in the manufacture of bread and other cereal based foods, reducing sugar may be cut down as far as possible and ingredients with reducing sugar should be avoided. Besides, measures for reducing the formation of acrylamide include using potassium or sodium containing raising agents to replace ammonium containing raising agents for biscuits and bakery wares, adding calcium carbonate for bread, and pre-processing with suitable additives (e.g. sodium pyrophosphate and calcium salts, etc.) for potato products.

(3) Food processing and heating:

Acrylamide is formed during food processing and heating stages. Therefore, adjusting a suitable cooking time, controlling the cooking temperature and food moisture are crucial factors in reducing the formation of acrylamide. Avoid baking, grilling or frying food excessively are also effective methods.

The Codex has also made recommendations on reducing the formation of acrylamide in certain foods in the CoP. For manufacture of bread, the duration of fermentation of bread doughs may be extended so as to reduce asparagine contents. For potato cultivars with higher levels of reducing sugars, blanching the potatoes in water and vacuum frying may decrease reducing sugar contents. For potatoes, a thick-cut strip contains less acrylamide than a fine-cut one. Optimising the cooking time and temperature to produce a crisp product with a pale golden yellow colour and removing dark coloured potato chips may reduce acrylamide contents in the products. Food manufacturers should conduct tests to identify the most suitable measures for their products.

The Codex has mentioned specifically in the CoP that measures on reducing the formation of acrylamide must take into account the considerations for food safety. Avoid introducing new measures that change the chemical composition and microbiological content in foods, hence affecting food safety. Besides, it should also be noted that the new measures should not change the nutritional values and organoleptic properties of the foods. When formulating new measures that are suitable for their products, manufacturers should be aware of these factors to ensure food safety and maintain product quality. To formulate new measures suitable for their products, the trade may visit the website of the Codex

(http://www.codexalimentarius.net/download/standards/11258/CXP_067e.pdf) for details on the CoP for the Reduction of Acrylamide in Foods.

(II) Amendment to the Sweeteners in Food Regulations

With a view to reflecting the latest development in food science and technology, and to keeping abreast of international standards, the Administration proposed to allow two more sweeteners, namely steviol glycosides and neotame, to be used in food. The Joint Food and Agriculture Organisation / World Health Organisation Expert Committee on Food Additives (JECFA) has evaluated both sweeteners and found that they are safe for use in food.

Steviol glycosides

Steviol glycosides (INS No. 960) are natural constituents of the plant Stevia rebaudiana Bertoni, a member of the Compositae family. The leaves of this plant contain at least ten different glycosides, the major constituents being stevioside and rebaudioside A. Steviol glycosides, which are 200 – 300 times sweeter than sucrose, have broad applications as sweetener in drinks, desserts, fruit products and table-top sweeteners.

Neotame

Neotame (INS No. 961) is a dipeptide methyl ester. Its chemical structure is similar to that of aspartame, another permitted sweetener. Neotame has a sweetness potency of 7 000-13 000 times that of sucrose. Being a high potency sweetener, neotame can be used to sweeten foods and beverages and as a table-top sweetener.

Permitted sweeteners in food

The Sweeteners in Food (Amendment) Regulation 2010 (the Amendment Regulation) proposes to add steviol glycosides and neotame to the list of permitted sweeteners. The Amendment Regulation was tabled at the Legislative Council on 26 May 2010. Having gone through the negative vetting procedure at the Legislative Council, the Amendment Regulation will take effect from 1 August 2010, whereas the types of sweeteners permitted to be used in food will increase from eight to ten, namely-

acesulfame potassium

alitame

aspartame

aspartame-acesulfame salt

cyclamic acid (and sodium, potassium, calcium salts)

saccharin (and sodium, potassium, calcium salts)

sucralose

thaumatin

steviol glycosides

neotame

Advice to the Trade

- Ensure that the food products comply with the requirements on food additives and labelling in local regulations.

- Adhere to the Good Manufacturing Practice in a way that only the lowest possible quantity of sweetener is added to food to enhance the sweetness.

Food News

Turn and Look for Healthier Food Choices

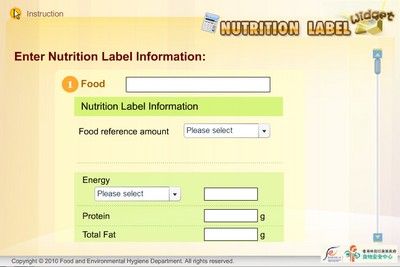

Nutrition Labelling Series – Nutrition Label Widget

The Nutrition Labelling Scheme comes into force on 1 July 2010. In order to enhance public understanding of nutrition labels and nutrition claims, the Centre for Food Safety has launched a dedicated website on nutrition labelling at www.nutritionlabel.gov.hk. In addition to disseminating information on nutrition labels and nutrition claims, the website also provides a device named Nutrition Label Widget for the public to compare energy and nutrient contents of different prepackaged foods and to calculate energy and nutrient intakes from prepackaged foods. We will explain how to use the Nutrition Label Widget in this issue.

Getting Started

- Start-up Nutrition Label Widget

- Click the link "Information for Consumers"

from www.nutritionlabel.gov.hk and select

from www.nutritionlabel.gov.hk and select  to activate Nutrition Label Widget.

to activate Nutrition Label Widget.

- Click the link "Information for Consumers"

- Enter information on nutrition label

-

After reading the instructions, start inputting the name of food and information on nutrition labels to the Widget.

-

Then, click

to enter into the calculation mode or select

to enter into the calculation mode or select  to enter into the comparison mode.

to enter into the comparison mode.

-

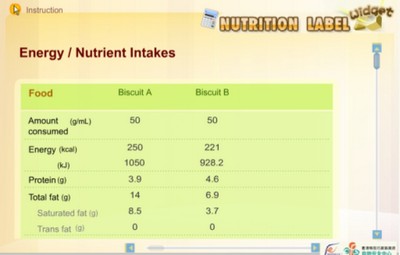

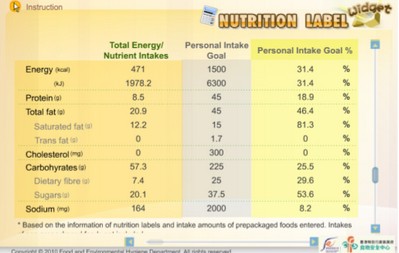

- Calculation Mode - Calculate energy and nutrient intakes from prepackaged food

-

Enter the amount of food consumed and then click

- The Widget will calculate the energy and nutrient intakes from the food.

And also the total energy and nutrient intakes.

-

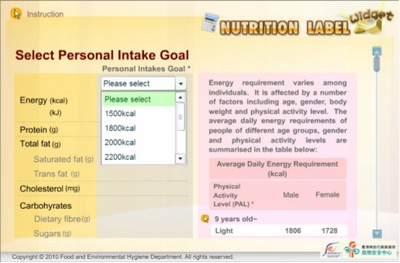

- Calculate Personal Intake Goal Percentage After Food Consumption

-

Click

- Refer to the information on gender, age and physical activity level on the right column and select your Personal Intakes Goal for energy.

- After clicking

, the Widget will calculate the nutrient intakes.

, the Widget will calculate the nutrient intakes. -

The Widget will also show the percentage of personal intake goal.

-

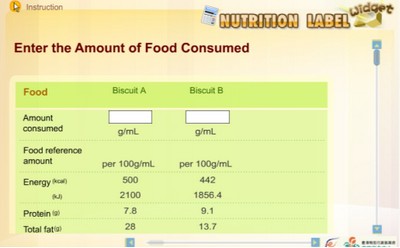

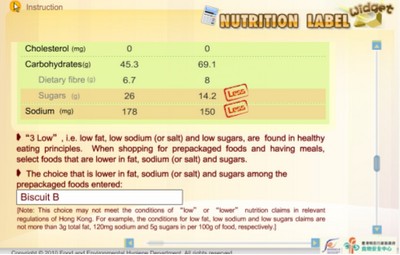

- Comparison Mode - Compare energy and nutrient contents of prepackaged food

-

Click.

-

If information of only one food product has been entered, please enter information on the nutrition label of other food product(s) before making the comparison.

-

Comparison is made on the basis of 100g/ml of food.

-

If the amount of total fat, sugars and sodium of a food product are less than that of the others, the Widget will list the recommended choice. For example:

-

As the Widget is so user-friendly, why not try it out on the internet? With the help of the Widget, you can compare the energy and nutrient contents of different food products and calculate the energy and nutrient intakes from the food concerned.

http://www.cfs.gov.hk/english/programme/programme_nifl/programme_nifl_public.html

Briefing of Activities

(I) Food Safety Day 2010

Food Safety Day is an annual highlight organised by the Centre for Food Safety (CFS). This year's Food Safety Day is on 28th June 2010, shortly before the implementation date of the Nutrition Labelling Scheme on 1 July 2010. The CFS joined hands with the Radio Television Hong Kong, the Education Bureau and the Committee on Home-School Co-operation in organising the Food Safety Day 2010 as a preface to the third phase of the Publicity and Education Campaign on Nutrition Labelling. With "For Your Health Count on Nutrition Label 1+7" as the theme, this year's event aimed to enhance understanding of nutrition labelling among students through various activities (such as interactive games and creative competitions) and to promote the use of nutrition labelling in achieving a healthy diet. The event was held at Hong Kong Southorn Stadium, Johnston Road, Wan Chai, Hong Kong on 28 June 2010.

(II) Food Safety Charter 2010

Proper food handling is an important measure by which to prevent foodborne diseases. The World Health Organisation (WHO) had previously developed the Ten Golden Rules for Safe Food Preparation, and subsequently grouped the messages under simpler headings and introduced the Five Keys to Safer Food poster for spreading WHO's food hygiene message throughout the world.

The Centre for Food Safety (CFS) launched the Food Safety Charter since 2008. Members of the food trade are invited to sign up to the Charter to promote the Five Keys to Food Safety in concerted effort. Building on the success in the past two years, the CFS will continue to invite food trade associations and licensed food premises to sign up to the Food Safety Charter 2010 to promote and practise the Five Keys to Food Safety. Members of the trade who wish to sign up to the Food Safety Charter 2010 may look out for CFS's announcement or visit its website at www.cfs.gov.hk for the latest information.

Food Safety Q&A

Question :

I always find dessicant (anti-moisture) packets inside food packages. How should they be handled?

Answer:

Desiccants are often included in food packages to maintain low humidity in the package, and in turn limit mould growth and extend shelf-life. Desiccants in food packages are usually in the form of small beads or powder, and are normally packed in sachets. Those small beads are silica gel. Being chemically and biologically inert, silica gel does not react with other substances easily, and does not cause harm to human if they ingest a small amount of silicia gel accidentally. The white powder is calcium oxide, also called quicklime. It becomes caustic when in contact with moisture and may cause burning sensation, stomach cramps and diarrhoea if swallowed accidentally.

Desiccant is not a food and thus food manufacturers should put up warning "Do Not Eat 請勿食用" on the sachets of dessicant in both English and Chinese. Furthermore, consumers are advised to discard the desiccant once the food package is opened to avoid accidental consumption. One should not eat the food if the sachet of desiccant is found broken.

Food Safety Plan Corner

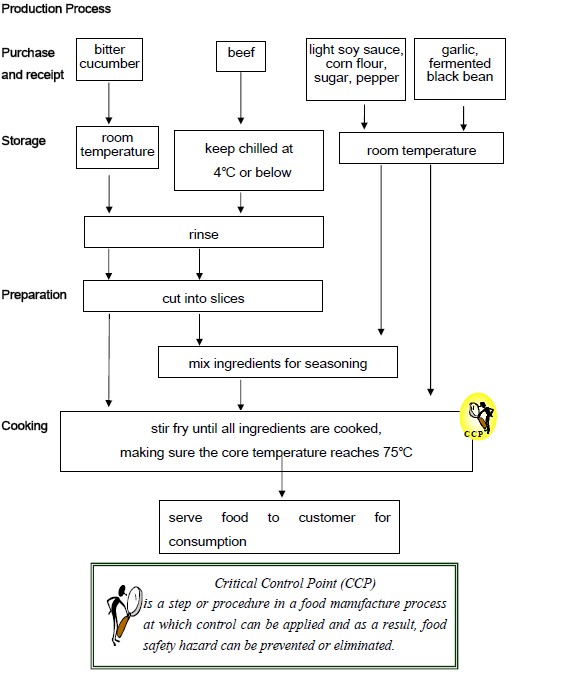

Critical Control Point of Preparing Stir-fried Bitter Cucumber with Beef

.jpg)

Despite the bitter taste, bitter cucumber is a popular food among Chinese. An experienced cook may marinate bitter cucumber in salt before cooking to reduce the bitterness.

In the following, we provide safety tips on preparing a popular dish called Stir-fried Bitter Cucumber with Beef. We demonstrate the application of a food safety management plan her while making this dish.

Ingredients

Fresh beef 200 grams (about 5 taels) ‧ Bitter cucumber 2 pieces.

Seasoning

Light soy sauce 1 teaspoon ‧ Corn flour 1 teaspoon ‧ Sugar 1 teaspoon

Pepper a little ‧ Garlic 5 grams ‧ Fermented black beans 5 grams

Steps:

- Rinse and cut bitter cucumber into slices.

- Cut beef into slices. Add light soy sauce, corn flour, sugar and pepper. Marinate for 15 minutes.

- Add oil into wok. Stir fry the beef in the wok lightly. Dish up for later use.

- Preheat the wok and add half a tablespoon of oil. Add garlic and fermented black beans. Stir fry until they smell good. Add bitter cucumber and stir fry until tender. Then add beef, stir fry evenly and serve.

Guidelines on Production of Stir-fried Bitter Cucumber with Beef

- Purchase and receipt

- Purchase the ingredients from reliable and hygienic shops.

- When buying and receiving the ingredients, make sure that:

- the ingredients are fresh and wholesome.

- the fresh beef is purchased from a licensed fresh provision shop.

- the bitter cucumber is neither damaged nor bruised on the surface.

- prepackaged food items (e.g. pepper, light soy sauce) are used before the expiry date.

- Storage

- Store the ingredients at safe temperature as soon as possible.

- Beef not for immediate use should be stored in a refrigerator. The temperature inside the refrigerator should be checked and recorded regularly with a thermometer to ensure that the fridge remains at 4℃ or below.

- Raw beef should be stored in a container with a lid and put under cooked food or ready-to-eat food to avoid cross-contamination. Raw food and cooked food should most preferably be stored in different refrigerators.

- Practise the first-in-first-out principle for storage. Check and record the storage date of the ingredients.

- Store the ingredients at safe temperature as soon as possible.

- Preparation

- Before cooking, wash all food contact surfaces (including worktops, chopping boards and utensils, etc.) thoroughly.

- Before cooking / in the course of preparing food, wash hands thoroughly with running water and liquid soap.

- Use two different sets of utensils (including knives, chopping boards, bowls and chopsticks) to handle raw food and cooked food separately.

- Before cooking, rinse the bitter cucumber and beef.

- Marinated beef not for immediate cooking should be stored in a refrigerator at 4℃ or below.

- Cooking

- The food should be thoroughly cooked before consumption until the meat juice becomes clear and not red.

- Use a clean food thermometer to measure the core temperature of the food, which should reach at least 75℃. (CCP)

- Management System

- Implement a preventive food safety management system (such as the Hazard Analysis Critical Control Point) to identify and control any food safety problems that may emerge during production.

Truth against Fallacy

Washing Vegetables

Fallacy

Vegetables available in the market are clean and can be consumed after a brief rinse.

Fact

Beisdes surface dirt, vegetables available on the market may be tainted with contaminants such as heavy metals and pesticide residues. To reduce the intake of contaminants due to consumption of tainted vegetables, members, of the public can wash vegetables well in clean running water for several times, then soak them in water for an hour or blanch them in boiling water for one minute and discard the water.

Answer

Enquiry and Subscription

Printed copies of the Food Safety Express can be collected at the Communication Resource Unit located at 8/F, Fa Yuen Street Municipal Services Building, 123A Fa Yuen Street, Mong Kok, Kowloon. For enquiry, please call 2381 6096. The public may also visit the website of the Centre for Food Safety (http://www.cfs.gov.hk) for the online version.