Feature Articles

(I) Hygienic handling of frozen confections to prevent food poisoning in hot summer

On a hot summer afternoon, Charlie came home from a football game. He casually took out a cup of ice-cream from the fridge, placed it on the table and rushed into the bathroom for a shower. Thirty minutes later,………

| Charlie: | Mom, I put an ice-cream on the table before taking a shower. Where is it now? |

|---|---|

| Mom: | Charlie, I have dumped it into the rubbish bin. |

| Charlie: | Why? The ice-cream hasn't gone bad yet, has it? |

| Mom: | Charlie, let me tell you how ice-cream is made. In the production of frozen confection, such as ice-cream in original wrappers, soft ice-cream, frozen yoghurt and sundae, heat treatment is applied to minimise microbiological hazards without causing undesirable changes to taste, texture or appearance of the food. After heat treatment, the products are kept at low temperature to prevent microbial growth at subsequent storage. |

| Charlie: | That means my ice-cream is safe to eat! |

| Mom: | Despite the heat treatment, contamination by pathogens in the environment or other food is possible at any point during processing, packaging, storage, delivery and retailing. Therefore, we should apply appropriate preventive measures to ensure they are safe for consumption. For example, ice-cream should be kept in the freezer at -18°C or below before it is consumed; otherwise, bacteria can multiply rapidly in the ice-cream at room temperature and food poisoning may result from eating such spoiled ice-cream. |

| Charlie: | Oh! If stored improperly, frozen confections may lead to food poisoning. So from now on, every time I bring home any ice-cream, I'll put it into the freezer immediately and only take it out when I am ready to eat it! |

Advice to Trade

- Obtain ingredients, such as milk, cream and ice-cream mix, from licensed and reputable sources, and inspect the ingredients before acceptance.

- Use the ingredients before their expiry dates.

- Store ingredients and final products at proper temperature (chilled items: 4°C or below; frozen items: -18°C or below).

- Check the temperature during transport and the temperature of equipment, like refrigerators, freezers and vending machines, regularly.

- Discard defrosted products and do not re-freeze any melted frozen confections for sale.

- For soft ice-cream, drain off and discard the leftover of soft ice-cream in the vending machines daily.

- Maintain all equipment and utensils in a clean and good condition; clean equipment and refrigerators, and sanitize them with approved disinfectants daily.

- Observe personal and environmental hygiene during all preparation and handling processes.

(II) Supplementary Information to Microbiological Guidelines for Ready-to-eat Food ("Supplementary Information")

As part of the Government's ongoing efforts to enhance food safety for the protection of public health and consumer interest, the Administration conducts regular review on microbiological food standards and guidelines and, where necessary, amends the standards / guidelines taking international standards and local situation into consideration. To facilitate monitoring and control of microbiological quality of bottled water, edible ice and non-bottled drinks, an Ad Hoc Working Group on Microbiological Safety of Food was formed in 2008 under the Expert Committee on Food Safety ("Expert Committee") to establish the microbiological criteria for bottled water and edible ice, and to review the microbiological criteria for non-bottled drinks. The Supplementary Information presents the criteria adopted by the Expert Committee. To familiarise the trade with the Supplementary Information, a trade seminar was organised on 24 April 2009 at the Lecture Hall of the Hong Kong Science Museum in Tsim Sha Tsui, and printed copies were distributed to the trade.

For a better understanding of the Supplementary Information, the public or the food trade can visit the website:

http://www.cfs.gov.hk/english/food_leg/files/sup_inf-microbio_r-t-e_guidelines_e_final_V1a.pdf

while the website:

http://www.cfs.gov.hk/english/faq/faq_11.html#sup_infoe

provides the frequently asked questions and answers relating to the Microbiological Guidelines for Ready-to-eat Food and the Supplementary Information.

(III) Human Swine Influenza and Food Safety

One day when Tommy came home after school ……

| Tommy: | Mom, I'm not going to school next week. Could you apply for leave of absence from school for me, please? |

|---|---|

| Mom: | There is an examination next week, isn't it? Why do you skip school? |

| Tommy: | Don't you know that there are confirmed cases of human swine influenza in Hong Kong ? I'm scared. I'd rather stay at home and not eating pork to prevent infection. |

| Mom: | Do you know what human swine flu exactly is? |

| Tommy: | ?????? |

| Mom: |

Human swine influenza is caused by influenza A/H1N1 virus. Its transmission occurs in the same way as seasonal flu, mainly through coughing or sneezing of infected people. We may also become infected by touching our nose or mouth after touching objects soiled with the virus. |

| Tommy: | Will eating pork cause infection? |

| Mom: | No, it won't. Human swine flu is not transmitted by food. Eating properly handled and cooked pork and pork products is safe. As a general rule, pork should be cooked thoroughly before consumption with central part of the pork reaching at least 75°C. |

| Tommy: | But I'm concerned that you might get infected when you handle raw pork! |

| Mom: | My dear Tommy. I'll not touch my face and other body parts when handling raw pork. Thereafter, I'll wash my hands thoroughly with warm soapy water and use hot water and detergent to cleanse all working surfaces, utensils and equipment that have been in contact with raw pork. There will be no room for slip-ups then. |

| Tommy: | We will also wash our hands with warm soapy water before and after meals. |

| Mom: | Well, your worries are now allayed. Go back to your room and prepare for your examination! |

| Tommy (murmuring): | Alas! I haven't read even a page of the book. The examination next week …… |

Advice to Trade

The food trade should remind their staff to observe good personal hygiene. If staff develop respiratory symptoms or fever, they should cease work immediately and see a doctor right away. Moreover, they could adopt the following measures to ensure food safety and environmental hygiene.

Choose

- Purchase pork from licensed fresh provision shops.

- Don't buy pork from questionable sources.

Clean

- Avoid touching raw pork directly when buying pork in the market.

- Observe good hygienic practices when handling raw pork. Upon touching raw pork, don't touch your face and other body parts. Thereafter, immediately wash hands thoroughly with warm soapy water. Thoroughly cleanse surfaces, utensils and equipment that have been in contact with raw pork with hot water and detergent.

- Tableware and towels provided to customers should be thoroughly washed before re-used. Provide customers with additional chopsticks or spoons for common serving of food.

- Provide liquid soap, disposable towels or hand-dryers in toilets.

- Step up cleansing and disinfection of the walls, floors, utensils, tables, chairs and equipment in the premises.

- Step up cleansing, inspection and maintenance of all ventilating systems in the premises, including air outlets, air filters, fresh air inlets and ventilating ducts.

- Keep the ventilating systems of the premises in operation during business hours.

Separate

- If raw pork is not used for immediate cooking, store it in a refrigerator. Raw food, including raw pork should be stored in containers with lids and put below cooked and ready-to-eat food.

- All food, beverages and tableware should be stored and covered properly.

Cook

- Pork should be cooked thoroughly before consumption with central part of the pork reaching at least 75°C.

Safe temperature

- Check the temperature of the refrigerator with a thermometer and ensure the fridge is kept at 4°C or below and the freezer at -18°C or below.

Readers' Corner

(I) Microbiological Risks of Siu-mei and Lo-mei

| Dad: | Son, the hawker ahead of us is selling BBQ pork and lo-mei. Let's buy some BBQ pork for your mom. |

|---|---|

| Fatty: | Dad, we have no idea if he is licensed or not, or if the BBQ pork he sells is hygienic or not! |

Siu-mei and lo-mei ( 燒味及鹵味 ), both traditional Chinese foods, are considered high-risk items in terms of microbiological risks. What should we do with them before we can consume them safely?

What are Siu-mei and Lo-mei?

Siu-mei is a group of meat products that has been roasted at a temperature of 200°C or above. Pork and poultry meat are often used for making siu-mei. Examples include roasted duck ( 燒鴨 ), roasted goose ( 燒鵝 ), roasted pork ( 燒肉、燒豬、燒排骨 ) and BBQ pork ( 叉 燒 ). Lo-mei is a foodstuff that has been soaked or immersed in large volumes of seasoning sauces prior to cooking. Some lo-mei items may be braised again after cooking and / or at the time of serving. Food groups that are commonly used to produce lo-mei include poultry meat ( 貴妃雞、豉油雞、鹵水鵝、鹵水雞肶及雞翼 ), red meat ( 鹵水牛肉 ) and offal products ( 鹵水雞腸、鵝腸及生腸 ).

Preparation of Siu-mei and Lo-mei

Roasting is the critical step to cook siu-mei products. At a temperature of 200°C or above, almost all microbiological hazards would be eliminated. The products are then cooled, delivered and displayed for sale. As for lo-mei, the main process involved is the use of marinade to impart the special taste and texture to the meat and offal. The meat and offal are first cooked with seasoning sauce or water, and then braised in the sauce for a period of time to enrich their flavour. The finished products can be served hot or cold.

Microbiological Risks of Siu-mei and Lo-mei

Some microorganisms, such as Campylobacter spp., Salmonella spp., Clostridium botulinum, Clostridium perfringens and Bacillus cereus, are the normal flora naturally present in raw meat and offal. Other microorganisms, such as Staphylococcus aureus, may be introduced during food preparation. In addition, the characteristics of the environment including relative humidity and temperature can influence the growth of microorganisms in siu-mei and lo-mei.

In terms of pathogenic contamination, Salmonella spp. and Staphylococcus aureus are the bacteria of concern. Salmonella spp. is commonly transmitted due to poor food and environmental hygiene, whereas Staphylococcus aureus is the normal flora found in hands and noses. Poor personal hygiene and post-heat treatment contamination are therefore the main reasons for the contamination of siu-mei and lo-mei by these bacteria. Moreover, storage of siu-mei and lo-mei for a prolonged period of time at ambient temperature is favourable for microbial growth. In view of these, we recommend the application of Hazard Analysis and Critical Control Point (HACCP) by the trade as the basis of the food safety plan to ensure food safety for siu-mei and lo-mei.

Advice to Trade

- Purchase

- Buy the ingredients, such as raw meat and offal, from approved and reliable sources.

- Inspect the incoming goods and documents before acceptance to verify that there is no sign of contamination or damage.

- Appropriate and clean vehicles should be used to transport the siu-mei and lo-mei. The siu-mei and lo-mei should be properly protected during transportation to avoid cross- contamination.

- Preparation

- Raw and cooked meats should be handled with separate utensils to avoid cross-contamination.

- Carefully estimate the demand for siu-mei and lo-mei to avoid over-production. This can prevent prolonged display and storage of siu-mei and lo-mei at ambient temperature.

- Observe good personal hygiene. No smoking, eating or hair stroking during preparation. Open wounds should be properly covered.

- Wash hands thoroughly with warm soapy water before and after handling siu-mei and lo-mei.

- Siu-mei and lo-mei should be thoroughly cooked.

- Display and Storage

- Store raw and cooked meats separately.

- Siu-mei and lo-mei should be stored and displayed in insect-proof and dust-proof cabinets.

- Foods other than siu-mei and lo-mei, especially raw foods such as seafood and Chinese preserved sausages, should not be stored in the same cabinet for siu-mei and lo-mei.

- Equipment including trays, towels, chopping boards and knives should be maintained in hygienic conditions and cleansed regularly.

- Different staff should be tasked with handling cash and food.

(II) Pathogens Commonly Found in Bakery Products

Master A met dispirited Master B in the road one morning.

| Master A: | Why are you in such low spirit? Did you lose a lot on the stock market? |

|---|---|

| Master B: | I made some losses. But the worst part is that just as I am putting all my effort into the bakery after the financial tsunami, a Health Inspector came the other day and said that my cakes were suspected of causing food poisoning. You can't have harder luck than that! |

| Master A: | What can you do about what already happened? Let's look forward and think about some remedial measures. Today I am going to have tea with a veteran of our trade. Let's ask him for advice. |

Over tea

| Veteran : | Actually, bakery foods are very common. In recent years, many bakeries introduce new varieties of bakery products in addition to the traditional ones in a bid to give their products a greater public appeal. Bakery products like fresh cream cakes, swiss rolls and tiramisu are very popular. These goodies may involve a number of manual procedures during production, and with higher health risks too. |

|---|---|

| Master B: | In fact, food safety is already my greatest concern. How could there be a problem still? |

| Veteran: | Do you know that the pathogens commonly found in bakery products include Staphylococcus aureus, Salmonella spp. and Bacillus cereus? Staphylococcus aureus is generally found in foods contaminated by contact with the unclean hands, noses or wounds of food handlers or customers. Salmonella spp. often comes from the ingredients of bakery products, such as eggs and meat used for stuffing. Bacillus cereus may be present in flour. If these bacteria are not killed in the production process and survive in the bakery products, or the environment is unhygienic and the temperature is improper for the keeping of bakery products, cross-contamination and proliferation of bacteria may occur. As a result, health problems or even food poisoning may result from the consumption of these foods. |

| Master B: | You are a true master. If I had met you earlier, I would not have found myself with the present problem. It is a great lesson for me! |

Advice to Trade

- Choose

- Purchase ingredients from hygienic and reliable suppliers.

- Specify delivery temperatures.

- Use safe raw materials (e.g. pasteurized egg pulp or cream).

- Check the quality of incoming raw materials and whether their expiry dates have passed.

- Separate

- Store bakery products and raw materials separately to avoid cross-contamination.

- Safe Temperature

- Store chilled food at 4°C or below, frozen food at -18°C or below.

- Cook

- Bake bread thoroughly.

For meat pies, core temperature of meat stuffing should reach at least 75°C.

- Bake bread thoroughly.

- Clean

- Observe personal and environmental hygiene.

- Wash hands thoroughly with warm soapy water before preparing food.

- Keep delivery vehicles clean.

- Use clean packaging tools, cover and package the products properly.

Food Safety Plan Corner

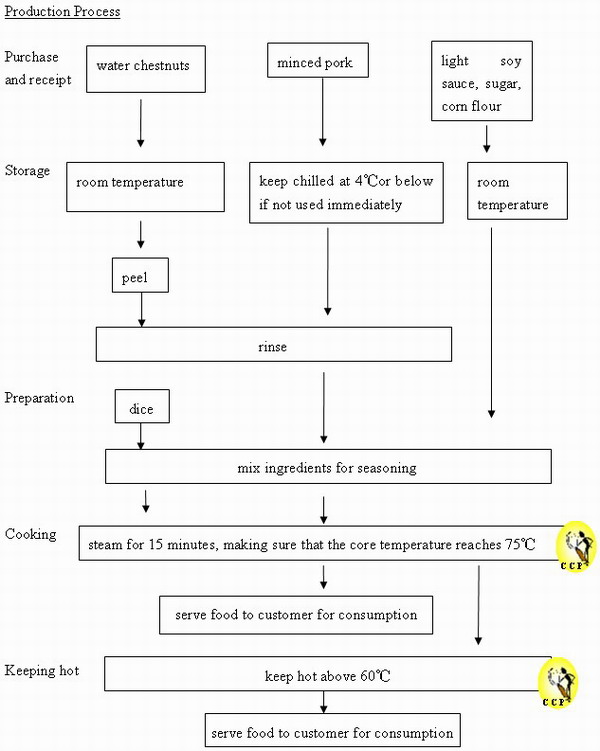

Critical Control Point of Preparing Steamed Minced Pork with Water Chestnut

Steaming, stir-frying, pan-frying and deep-frying are the most common cooking methods. Unlike the other three methods, steaming does not need additional oil, making it a low-fat and healthier way of cooking. A steamed dish, i.e. steamed minced pork with water chestnut, is chosen this time for introducing and illustrating the Critical Control Points during preparation. By ensuring food safety at all times, your customers can enjoy the food safely.

Ingredients

| Fresh minced pork | 300 grams (about 8 taels) |

|---|---|

| Water chestnut | 6 pieces |

Seasoning

| Light soy sauce | 1 teaspoon |

|---|---|

| Sugar | 1/2 teaspoon |

| Corn flour | 1 teaspoon |

Steps

- Peel, rinse and dice water chestnuts.

- Add water chestnuts and seasoning into the minced pork, mixing well. Marinate for 15 minutes.

- Steam for 15 minutes on high heat.

Guidelines on Production of Steamed Minced Pork with Water Chestnut

- Purchase and receipt

- Purchase the ingredients from reliable and hygienic suppliers.

- When buying and receiving the ingredients, make sure that:

- the ingredients are fresh and wholesome.

- the fresh minced pork is purchased from a licensed fresh provision shop.

- the water chestnuts are neither damaged nor bruised on the surface.

- prepackaged food items (e.g. sugar, corn flour) are used before the expiry date.

- Storage

- Store the ingredients immediately at safe temperature as soon as possible.

- Minced pork not for immediate use should be stored in a refrigerator. The temperature inside the refrigerator should be checked regularly with a thermometer and recorded to ensure that the fridge remains at 4°C or below.

- Raw minced pork should be stored in a container with a lid, and put under cooked food or ready-to-eat food to avoid cross-contamination. Raw food and cooked food should most preferably be stored in different refrigerators.

- Practise the first-in-first-out principle for storage. Check and record the storage date of the ingredients.

- Store the ingredients immediately at safe temperature as soon as possible.

- Preparation

- Before cooking, wash all food contact surfaces (including worktops, chopping boards and utensils) thoroughly.

- Before cooking / in the course of preparing food, wash hands thoroughly with warm soapy water.

- Use two different sets of utensils (including knives, chopping boards, bowls and chopsticks) to handle raw and cooked food separately.

- Before cooking, rinse the minced pork and water chestnuts.

- Marinated pork not for cooking immediately should be stored in a refrigerator at 4°C or below.

- Cooking

- The food should be thoroughly cooked before consumption until the meat juice becomes clear and not red.

- Use a clean food thermometer to measure the core temperature of the food, which should reach at least 75℃. (CCP)

- Keeping hot / Consumption

- The cooked food should be served to customers for consumption as soon as possible. It should not be kept at room temperature for more than 2 hours.

- The food not for immediate consumption should be kept hot in a pre-heated plate or steamed pot above 60℃. (CCP)

- Management System

- A preventive food safety management system (such as the Hazard Analysis Critical Control Point) should be implemented to identify and control any food safety problems that may emerge during production.

Food News

Turn and Look - For Healthier Food Choices

Nutrition Labelling Series – Measuring Units for Nutrients

In the last issue, we introduced energy and its measuring units. In this issue, we would like to provide you with answers to some of the questions concerning units for nutrients.

Question 1: Are measuring units for nutrient contents the same as units for weight?

Generally speaking, measuring units for nutrient contents are units for weight. For measuring nutrient contents, metric units (e.g. gram, milligram or microgram) are used in the international community. Therefore, we usually say 60 grams of protein and 1 000 milligrams of calcium, instead of 2 ounces of protein and 0.003 ounce of calcium.

Question 2: Why is the measuring unit for Vitamin A (μg Retinol Equivalents) different from the units for other nutrients?

More than one type of similar bioactive compounds (e.g. β-carotene, α - carotene) can be converted into Vitamin A (its scientific name is known as "Retinol") in the human body. And the conversion rate and absorption rate of various bioactive compounds are different (e.g. 6 μg of β-carotene is only equal to 1 μg of Vitamin A). Therefore, the content of these bioactive compounds cannot be directly applied in calculating the total content of Vitamin A.

To accurately calculate the total content of Vitamin A in food, all bioactive compounds must first be converted to Vitamin A (or Retinol Equivalents), and then added up as the total. The unit for calculating Vitamin A is therefore known as μg Retinol Equivalents (μgRE), which refers to the total content of Vitamin A and the bioactive compounds. A similar concept also applies to the calculation of Vitamin E (unit for calculation: α-Tocopherol Equivalents (mg α-TE)) and folic acid (unit for calculation: μg Dietary Folate Equivalents (μg DFE)).

Question 3: Why is Vitamin A expressed in international units (IU) on some nutrition labels?

International Units (IU), commonly used in the past (1 μgRE= 3.33 IU), are less often used nowadays. Under the regulation on nutrition labeling, to come into force in July 2010, all nutrients should be expressed in metric units (i.e. gram, milligram or microgram).

Briefing of Activities

(I) Regional Symposium on Regulation of Pesticide Residues in Food

The Centre for Food Safety (CFS) and the European Commission (EC) jointly organised the Regional Symposium on Regulation of Pesticide Residues in Food (the "Symposium") on 27 and 28 March 2009 at Hotel Nikko Hongkong in Tsim Sha Tsui. The aim of this one-and-a-half-day Symposium was to keep participants abreast of the latest development in the regulation of pesticide residues in food in the international arena. Topics of the Symposium centred around three areas of pesticide residues in food, namely regulatory control, risk assessment and standard setting. It was our honour to have a number of distinguished speakers from Mainland China and overseas food safety authorities, in addition to the experts from the European Union, to share with us their experience, expertise and insight in these areas.

We were also very honoured to have Mr CHEUK Wing-hing, J.P., Director of Food and Environmental Hygiene and Mrs Maria CASTILLO FERNANDEZ, Head of Office of the European Commission in Hong Kong and Macao to deliver opening speeches. Speakers of the Symposium were Mr Denis J. HAMILTON, representative of the Joint FAO/WHO Meeting on Pesticide Residues; Dr. Francesca ARENA, Administrator, Health and Consumers Directorate General, European Commission; Professor Ying JI, Director of Pesticide Residue Control Division, Institute for the Control of Agrochemicals, Ministry of Agriculture, The People's Republic of China; Dr. Peter CHAN, Director General, Health Evaluation Directorate, Pest Management Regulatory Agency, Health Canada; Dr. Paul BRENT, Chief Scientist, Food Standards Australia New Zealand; Ms Hermine REICH, Senior Scientific Officer, European Food Safety Authority; Dr. Karsten HOHGARDT, Scientific Director, Head of Unit Health, Federal Office of Consumer Protection and Food Safety, Germany; and Dr. Anne FUNG, Principal Medical Officer of the CFS.

The Symposium brought together over 140 participants from the food trade, academia, Government departments and relevant authorities of the Mainland and Macao . Participants actively exchanged their views and ideas on the regulation of pesticide residues in food. They found the arrangement of the Symposium to their great satisfaction and expressed that the detailed accounts given by various speakers and discussions during the one-and-a-half-day Symposium had enhanced their understanding of the latest development in the regulatory control of pesticide residues in food in the international front and the proposed regulatory framework locally in Hong Kong . Both Ms Marie-Paule BENASSI, First Counsellor-Food Safety, Health and Consumer Protection, Delegation of the European Commission in Beijing , China and Dr. Constance CHAN, Controller of the CFS highly commended the Symposium in their closing addresses. Please visit the following CFS web page for the speakers' presentation materials and the photo gallery of the Symposium:

http://www.cfs.gov.hk/english/whatsnew/whatsnew_act/whatsnew_act_21_introduction_

on_symposium.html

(II) Nutrition Label Calculator

Providing nutrition information on food labels is an important public health tool to promote a balanced diet as consumers can obtain specific nutrition information on individual food products and make healthy food choices. The Centre for Food Safety (CFS) has developed an online Nutrition Label Calculator (NLC) which enables food manufacturers and traders to prepare nutrition labels for prepackaged food products in compliance with the Food and Drugs (Composition and Labelling) (Amendment: Requirements for Nutrition Labelling and Nutrition Claim) Regulation 2008. The NLC can facilitate users to make nutrition labels basing on the nutrition information of foods obtained by direct chemical analysis of food samples or indirect nutrient analysis of food ingredients. The labels can be generated in various formats (e.g. tabular format or linear format) in Chinese, English or in both languages. Nutrient contents in foods can also be expressed in different ways: per 100 grams (g) or per 100 millilitres (ml), per package or per serving and in percentage of Nutrient Reference Values (NRV) etc. Apart from energy and the seven nutrients which are mandatorily required to be labelled, users may include other nutrient values in labels. The CFS has held a sharing session in mid-June and shared the experience in using the NLC with the trade. For details of the NLC, please visit the following web page of the CFS:

http://www.cfs.gov.hk/english/programme/programme_nifl/nlc-intro.html

(III) Food Safety Seminar for Trade

The Centre for Food Safety (CFS) will hold a one-day Food Safety Seminar for Trade on 17 September 2009 at the Lecture Theatre of the Hong Kong Central Library in Causeway Bay . During the seminar, doctors and health inspectors of the CFS will talk about food safety issues that are of concern to the trade. The CFS aims to inform the trade of the latest regulatory requirements and guidelines on food safety, thereby strengthening the tripartite collaboration among the Government, the food trade and consumers, and ensuring that food sold in Hong Kong is safe and fit for human consumption.

A presentation ceremony of Food Safety Charter 2009 is scheduled to be held on the same day. The CFS will later send letters to members of the trade, inviting them to attend the seminar. They may also look for related announcements on the web page of the CFS.

(IV) Food Safety Charter 2009

In 2008, the Centre for Food Safety (CFS) launched the Food Safety Charter 2008 in the hope of joining hands with the trade to promote the 5 Keys to Food Safety. The 5 Keys to Food Safety, namely, Choose, Clean, Separate, Cook and Safe Temperature, are the five simple and effective keys advocated by the World Health Organization to prevent food-borne diseases. The campaign was warmly welcomed by the trade, with a total of 20 food trade associations and over 1600 licensed food premises / supermarkets / convenience stores participating. After the successful implementation of Food Safety Charter 2008, the CFS, to continue to promote food safety, sincerely invites food trade associations and licensed food premises to participate in Food Safety Charter 2009. For more details, please look for announcements on the CFS web page (www.cfs.gov.hk).

Brief Notes on the Legislation

Amendment to the Chinese Rendition of "Use by" Date on Labels of Prepackaged Foods

The proposed amendment to the Chinese rendition of "use by" date on labels of prepackaged foods was passed by the Legislative Council on 30 April 2008 and published in the Gazette on 9 May 2008. The amendment intends to better reflect the legislative intent and to tie in with the Chinese translation of "use by" date (" 此日期或之前食用 ") in Schedule 6 to the Food Business Regulations, Cap. 132X on the labelling of chilled beef, mutton or pork. The amendment aims to replace the Chinese rendition of "use by" date (" 此日期前食用 ") in the provisions of the Food and Drugs (Composition and Labelling) Regulations, Cap. 132W by " 此日期或之前食用 " . The amendment will take effect on 1 July 2010 . The relevant notice was published in the Gazette in May 2009. The trade may change the labels during the transition period before 30 June 2010 . The trade should note that only the Chinese rendition will be amended while the English wordings remain unchanged. Moreover, no amendments have been made to the wordings of "best before" date (" 此日期前最佳 "). For details of the amendment, please visit the CFS web page (http://www.cfs.gov.hk) for the relevant information.